Are you gearing up for an interview for a Glassware Finisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glassware Finisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

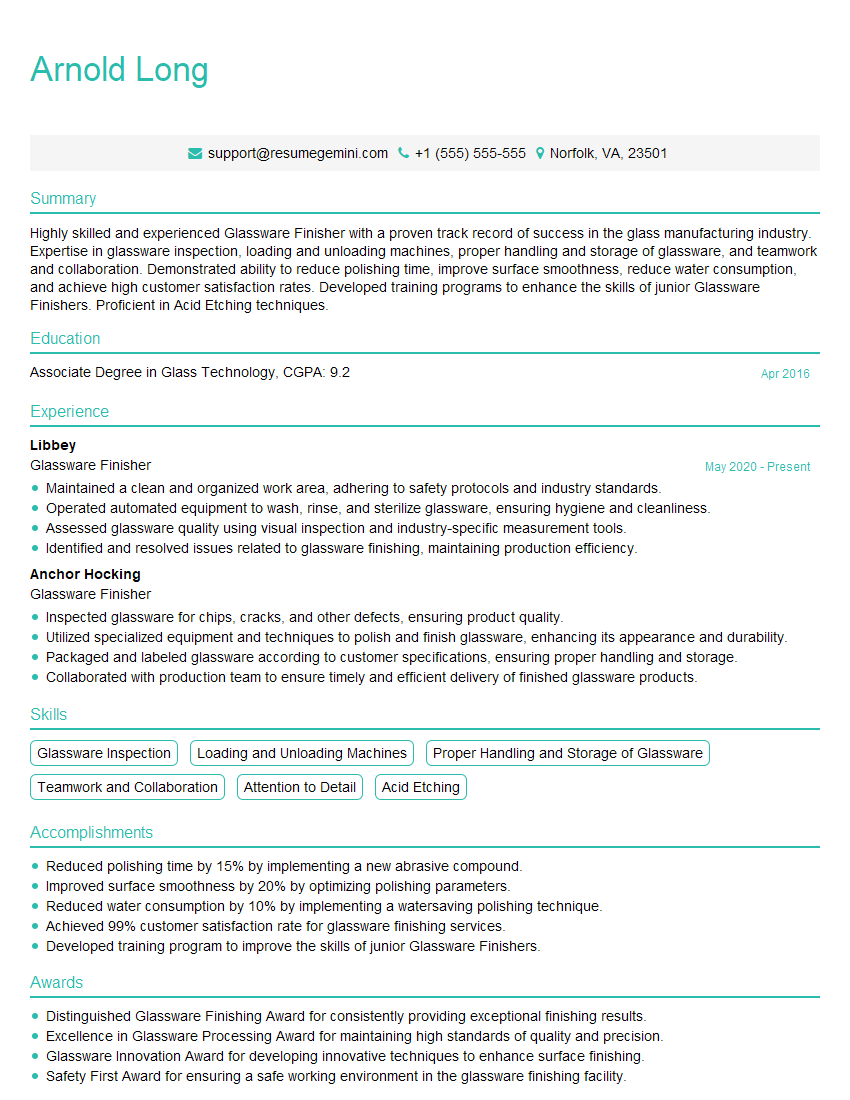

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glassware Finisher

1. What is the process of glassware finishing?

- Glassware finishing is the final stage in the production of glassware, where the raw glass is transformed into a finished product.

- The process involves a variety of techniques, including cutting, grinding, polishing, and decorating.

- The goal of glassware finishing is to create a product that is both visually appealing and functional.

2. What are the different types of glassware finishing techniques?

Cutting:

- Cutting is used to create the basic shape of the glassware.

- This can be done using a variety of tools, including diamond saws, water jets, and lasers.

Grinding:

- Grinding is used to smooth the edges of the glassware and to create a more uniform surface.

- This can be done using a variety of abrasive materials, such as sand, pumice, and carbide.

Polishing:

- Polishing is used to create a smooth, shiny surface on the glassware.

- This can be done using a variety of polishing compounds, such as cerium oxide and diamond paste.

Decorating:

- Decorating is used to add a decorative element to the glassware.

- This can be done using a variety of techniques, such as sandblasting, etching, and engraving.

3. What are the important physical properties of glassware that you should be aware of?

- Strength: Glassware is a relatively strong material, but it can be easily damaged by impact or thermal shock.

- Hardness: Glassware is a hard material, but it can be scratched by harder materials, such as diamonds and tungsten carbide.

- Brittleness: Glassware is a brittle material, which means that it can break easily if it is subjected to a sudden impact or a sharp change in temperature.

- Transparency: Glassware is a transparent material, which means that it allows light to pass through it.

- Thermal conductivity: Glassware is a poor conductor of heat, which means that it does not transfer heat well.

4. What are the safety precautions that must be followed when working with glassware?

- Always wear safety glasses when working with glassware.

- Never handle glassware with bare hands. Always use gloves.

- Do not use glassware that is chipped or cracked.

- Do not heat glassware directly over an open flame.

- Do not cool glassware too quickly. This can cause it to crack.

- Store glassware in a safe place where it will not be knocked over or damaged.

- Dispose of broken glassware properly.

5. What are the different types of glassware that you have worked with?

- Borosilicate glass

- Soda-lime glass

- Lead glass

- Crystal glass

- Fused quartz

6. What are the challenges of working as a glassware finisher?

- The work can be repetitive and physically demanding.

- The working conditions can be hot and humid.

- There is a risk of injury from sharp edges and broken glass.

- The work can be stressful, as there is often a high demand for quality products.

7. What are the rewards of working as a glassware finisher?

- The work is challenging and rewarding.

- The work can be creative and expressive.

- The work is often in high demand.

- The work can pay well.

8. What are your career goals?

- I would like to become a master glassware finisher.

- I would like to learn new glassware finishing techniques.

- I would like to work with different types of glassware.

- I would like to eventually start my own glassware finishing business.

9. What are your strengths as a glassware finisher?

- I am a hard worker.

- I am a quick learner.

- I am a perfectionist.

- I am a team player.

10. What are your weaknesses as a glassware finisher?

- I am sometimes impatient.

- I can be a bit of a perfectionist.

- I am not always the best at working under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glassware Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glassware Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Glassware Finisher is responsible for ensuring that glassware is properly cleaned, sterilized, and prepared for use in a laboratory or other scientific setting. Glassware Finishers meticulously inspect and handle glassware to maintain the highest levels of cleanliness and accuracy, playing a crucial role in the smooth operation of scientific experiments and research.

1. Cleaning and Sterilizing Glassware

Glassware Finishers thoroughly clean and sterilize glassware using appropriate techniques and detergents.

- Manually or mechanically wash glassware to remove dirt, debris, and contaminants.

- Immerse glassware in sterilizing solutions to eliminate microorganisms.

- Rinse and dry glassware to ensure complete removal of cleaning agents and sterilization residues.

2. Inspection and Quality Control

Glassware Finishers meticulously inspect glassware for any defects or damage that could compromise their integrity.

- Visually inspect glassware for cracks, chips, or other imperfections.

- Check glassware for cleanliness and freedom from contaminants or residues.

- Identify and discard any glassware that does not meet quality standards.

3. Packaging and Storage

Glassware Finishers carefully package and store glassware to protect it from damage and contamination.

- Wrap glassware in protective materials, such as paper or foam, to prevent breakage.

- Store glassware in designated areas to maintain cleanliness and organization.

- Label and track glassware for inventory and traceability purposes.

4. Maintenance and Calibration

Glassware Finishers assist in maintaining and calibrating equipment used in the cleaning and sterilization process.

- Monitor and adjust equipment settings to ensure optimal cleaning and sterilization.

- Calibrate equipment regularly to maintain accuracy and reliability.

- Perform routine maintenance tasks to extend equipment lifespan and prevent breakdowns.

Interview Tips

Preparing for a Glassware Finisher interview requires thorough research and a clear understanding of the role’s responsibilities. Here are some tips to help candidates ace the interview:

1. Research the Organization and Position

Familiarize yourself with the laboratory or organization you are applying to and the specific requirements of the Glassware Finisher position.

- Review the organization’s website and mission statement.

- Identify the laboratory’s research areas and specialized equipment.

- Study the job description thoroughly to understand the expectations and responsibilities.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in glassware handling, cleaning, and sterilization techniques.

- Quantify your experience in cleaning and sterilizing glassware in a laboratory setting.

- Provide specific examples of how you have ensured the accuracy and quality of glassware.

- Highlight your attention to detail and commitment to maintaining a clean and organized work environment.

3. Demonstrate Knowledge of Laboratory Procedures

Show that you understand the importance of following laboratory protocols and safety guidelines.

- Explain your knowledge of proper glassware handling techniques to prevent breakage and contamination.

- Discuss your understanding of laboratory safety procedures and emergency protocols.

- Describe how you would maintain a sterile working environment to prevent cross-contamination.

4. Be Enthusiastic and Professional

Convey your enthusiasm for the position and the field of laboratory science.

- Express your interest in working in a laboratory environment and contributing to scientific research.

- Show your eagerness to learn new techniques and procedures.

- Maintain a professional demeanor throughout the interview and ask insightful questions.

Next Step:

Now that you’re armed with the knowledge of Glassware Finisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Glassware Finisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini