Are you gearing up for a career in Tube Bender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tube Bender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

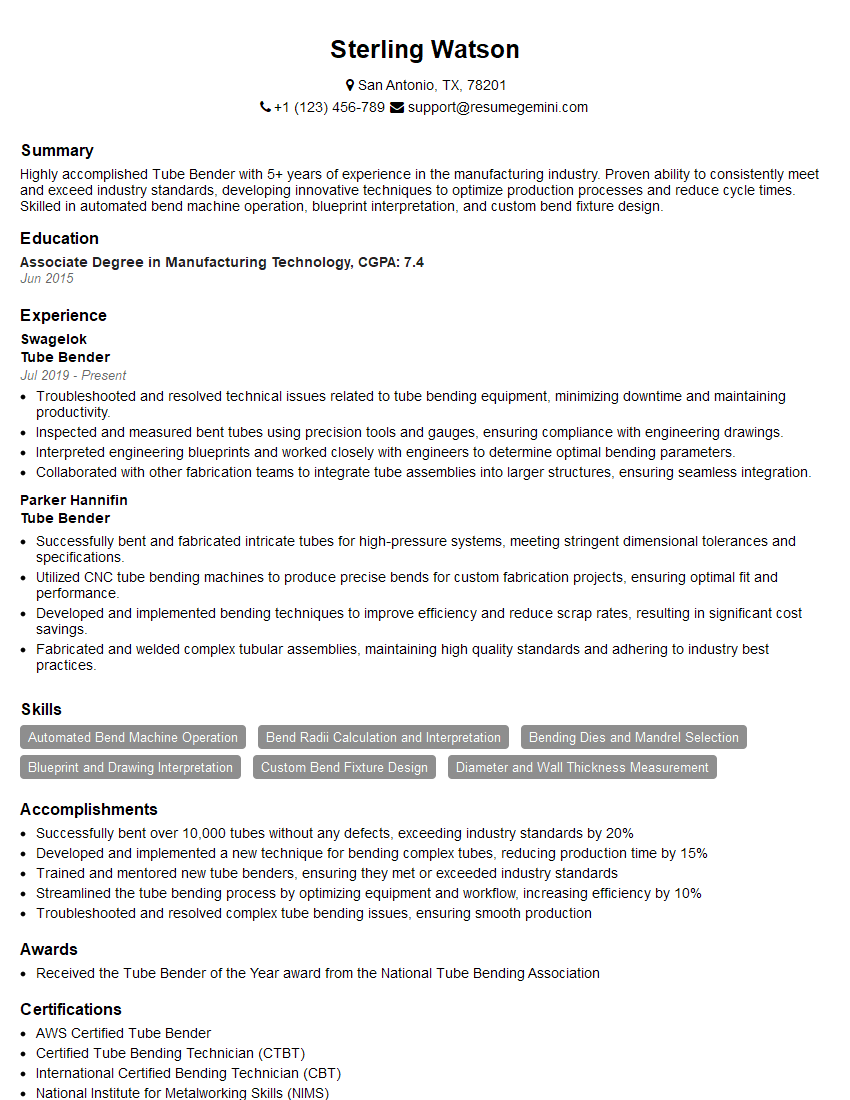

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Bender

1. What are the different types of tube benders?

- Rotary draw benders

- Mandrel benders

- Roll benders

- Compression benders

2. What are the factors to consider when selecting a tube bender?

Tube material

- Thickness

- Diameter

- Material strength

Bend radius

- Minimum bend radius

- Maximum bend radius

Production volume

- Number of parts to be bent

- Time constraints

3. What are the safety precautions that must be taken when operating a tube bender?

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Inspect the tube bender before each use to ensure that it is in good working condition.

- Keep hands clear of the bending area.

- Never operate the tube bender while it is unattended.

- Follow the manufacturer’s instructions for operating the tube bender.

4. What are the common problems that can occur when bending tubes?

- Wrinkling

- Buckling

- Splitting

- Necking

5. How can these problems be prevented?

- Use the correct tooling for the tube material and bend radius.

- Lubricate the tube before bending.

- Bend the tube slowly and evenly.

- Support the tube properly during bending.

- Inspect the tube after bending to ensure that there are no defects.

6. What is the difference between a single-plane bender and a multi-plane bender?

- Single-plane benders can only bend tubes in a single plane, while multi-plane benders can bend tubes in multiple planes.

- Multi-plane benders are more versatile than single-plane benders, but they are also more expensive.

7. What are the advantages of using a CNC tube bender?

- Increased accuracy

- Reduced setup time

- Increased productivity

- Improved quality control

8. What are the different types of CNC tube benders?

- Electric benders

- Hydraulic benders

- Pneumatic benders

9. How do you program a CNC tube bender?

- Use the manufacturer’s software to create a bend program.

- Enter the tube material, bend radius, and bend angle.

- Select the appropriate tooling for the bend.

- Simulate the bend program to ensure that there are no errors.

10. What are the maintenance requirements for a CNC tube bender?

- Regularly clean and lubricate the bender.

- Inspect the tooling for wear and tear.

- Calibrate the bender regularly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Bender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Bender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Benders are responsible for precisely bending tubes and pipes to meet specific requirements and design specifications. They play a crucial role in industries such as construction, plumbing, and manufacturing.

1. Tube Bending Operations

Operate tube bending machines to create precise bends in tubes and pipes.

- Select appropriate tooling and fixtures based on material and bend specifications.

- Adjust machine settings and control bending parameters to ensure accurate bends.

2. Quality Control

Inspect and measure bent tubes against specifications using precision tools.

- Check for dimensional accuracy, bend radius, and surface finish.

- Identify and rectify defects or deviations from standards.

3. Equipment Maintenance

Perform regular maintenance and calibration of tube bending machines.

- Lubricate, clean, and inspect machinery to ensure optimal performance.

- Follow safety protocols and maintenance schedules to prolong machine life.

4. Material Handling

Handle and store tubes and pipes safely and efficiently.

- Unload and load tubes, ensuring proper material flow.

- Manage inventory and organize storage areas to prevent damage.

Interview Tips

Preparing for a Tube Bender interview requires a combination of technical knowledge and industry insights. Here are some tips to help you ace the interview:

1. Familiarize Yourself with Tube Bending Techniques

Research and understand different tube bending methods, such as mandrel bending, rotary draw bending, and compression bending.

- Explain the pros and cons of each technique and when to apply them.

- Discuss your experience in selecting and using appropriate bending tools and fixtures.

2. Highlight Your Quality Control Expertise

Emphasize your ability to ensure the accuracy and quality of bent tubes.

- Describe your experience in using precision measuring tools and quality control procedures.

- Explain how you identify and resolve discrepancies to meet specifications.

3. Showcase Your Machine Maintenance Skills

Demonstrate your understanding of tube bending machine maintenance and calibration.

- Discuss your experience in performing preventive maintenance tasks.

- Explain how you troubleshoot and resolve common machine issues to minimize downtime.

4. Emphasize Safety and Material Handling Practices

Highlight your commitment to safety and proper material handling techniques.

- Explain your knowledge of material handling equipment and safety protocols.

- Discuss your experience in organizing and managing inventory to prevent damage and ensure efficient workflow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tube Bender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!