Are you gearing up for a career in Hand Molder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hand Molder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

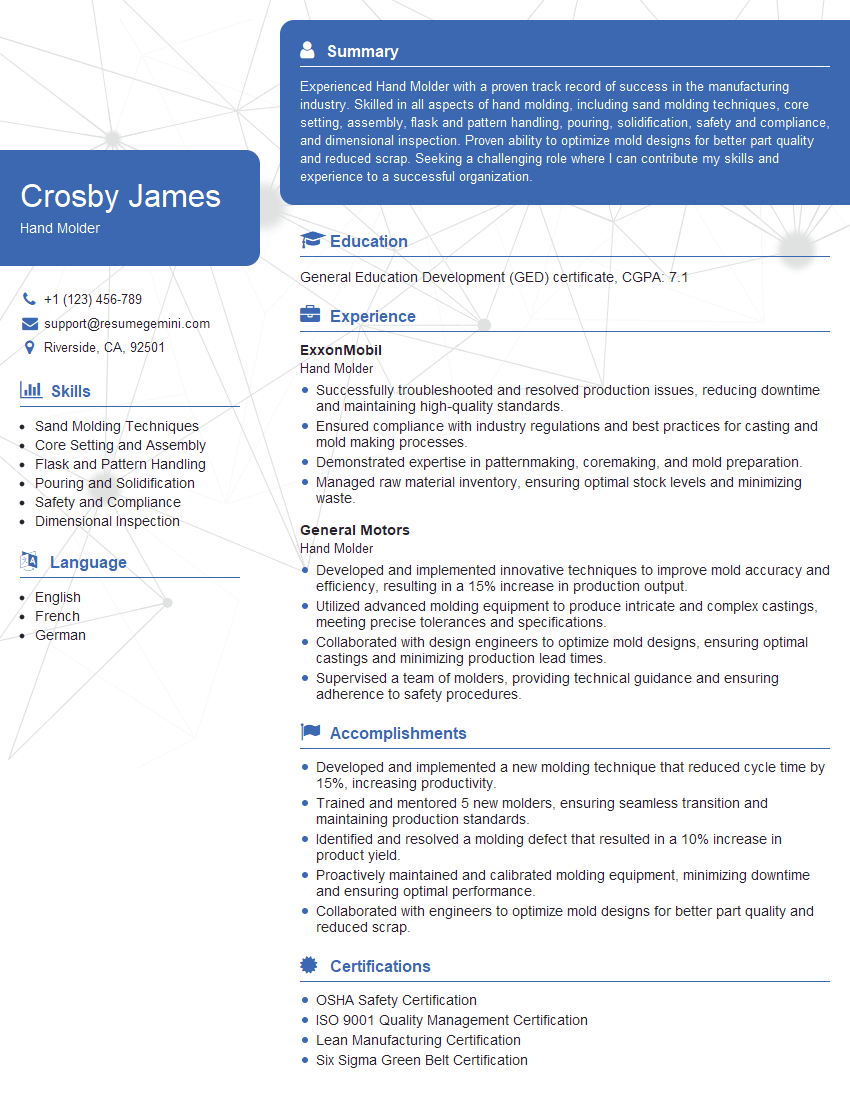

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Molder

1. Describe the steps involved in the hand molding process?

The hand molding process typically involves the following steps:

- Prepare the pattern and mold box.

- Create the mold.

- Prepare the molten metal.

- Pour the molten metal into the mold.

- Allow the metal to cool and solidify.

- Remove the casting from the mold.

- Clean and inspect the casting.

2. What are the different types of molding materials used in hand molding?

Sand

- Green sand

- Dry sand

- Oil sand

- Chemical sand

Other materials

- Plaster

- Metal

- Ceramic

3. How do you ensure the quality of hand-molded castings?

- Use high-quality materials.

- Follow the molding process carefully.

- Inspect the castings thoroughly.

- Make adjustments to the process as needed.

4. What are the common defects that can occur in hand-molded castings?

- Shrinkage

- Porosity

- Cold shuts

- Misruns

- Cracks

5. How do you prevent defects in hand-molded castings?

- Use the correct materials

- Follow the molding process carefully

- Inspect the castings thoroughly

- Make adjustments to the process as needed

6. What are the different types of patterns used in hand molding?

- Single-piece patterns

- Split patterns

- Gated patterns

- Cope and drag patterns

7. How do you choose the right pattern for a hand molding project?

- Consider the size and complexity of the casting.

- Consider the type of metal being cast.

- Consider the available resources.

8. What are the different types of molding machines used in hand molding?

- Hand-operated molding machines

- Pneumatic molding machines

- Hydraulic molding machines

9. How do you operate a hand-operated molding machine?

To operate a hand-operated molding machine, you will need to follow these steps:

- Place the pattern on the molding board.

- Fill the flask with sand and pack it down.

- Draw the pattern from the sand.

- Create the mold.

- Pour the molten metal into the mold.

- Allow the metal to cool and solidify.

- Remove the casting from the mold.

10. What are the safety precautions that should be taken when operating a molding machine?

- Wear proper safety gear.

- Keep the work area clean and free of debris.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

- Follow all safety instructions provided by the manufacturer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Pattern Analysis and Mold Preparation

The Hand Molder is responsible for accurately analyzing patterns to determine the proper molding techniques and materials

- Studying patterns and blueprints to understand the design and dimensions of the mold

- Selecting and preparing molding materials, such as sand, clay, or metal

- Creating mold cavities by packing and shaping the molding material around the pattern

2. Molding and Casting

The Hand Molder uses various techniques to create molds and cast metal into desired shapes

- Pouring molten metal into the mold cavity and allowing it to solidify

- Removing the casting from the mold after it has cooled and solidified

- Inspecting castings for defects and ensuring they meet quality standards

3. Equipment Maintenance and Troubleshooting

To ensure smooth operations, the Hand Molder is responsible for maintaining equipment and troubleshooting issues

- Performing routine maintenance on molding machines, conveyors, and other equipment

- Identifying and resolving equipment malfunctions and production problems

- Maintaining a clean and organized work area

4. Safety Compliance

The Hand Molder prioritizes safety in the workplace by adhering to established protocols and regulations

- Wearing appropriate safety gear, such as gloves, safety glasses, and protective clothing

- Following safety procedures for handling hazardous materials, such as molten metal

- Maintaining a safe work environment by identifying and eliminating potential hazards

Interview Tips

1. Research the Company and Role

Demonstrate your enthusiasm and preparation by researching the company’s background, products/services, and the specific role you’re applying for

- Visit the company website to learn about their mission, values, and industry standing

- Read industry publications and news articles to stay updated on trends and best practices

- Network with professionals in the field to gain insights into the company and the role

2. Highlight Your Skills and Experience

Quantify your accomplishments using specific metrics and examples to demonstrate your abilities

- Emphasize your proficiency in pattern analysis, mold preparation, and casting techniques

- Showcase your experience in maintaining and troubleshooting molding equipment

- Highlight your commitment to safety and adherence to industry standards

3. Prepare for Common Interview Questions

Anticipate and prepare thoughtful responses to common interview questions

- Tell me about your experience in hand molding and casting

- Describe a situation where you successfully resolved a problem with molding equipment

- How do you ensure the accuracy and quality of your castings?

- What are your strengths and weaknesses as a Hand Molder?

4. Ask Insightful Questions

Show your engagement and curiosity by asking thoughtful questions to the interviewer

- Inquire about the company’s current projects and future plans

- Ask about the specific challenges and opportunities associated with the role

- Request information about the company’s training and development programs

- Thank the interviewer for their time and express your continued interest in the position

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hand Molder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.