Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mold Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mold Mechanic so you can tailor your answers to impress potential employers.

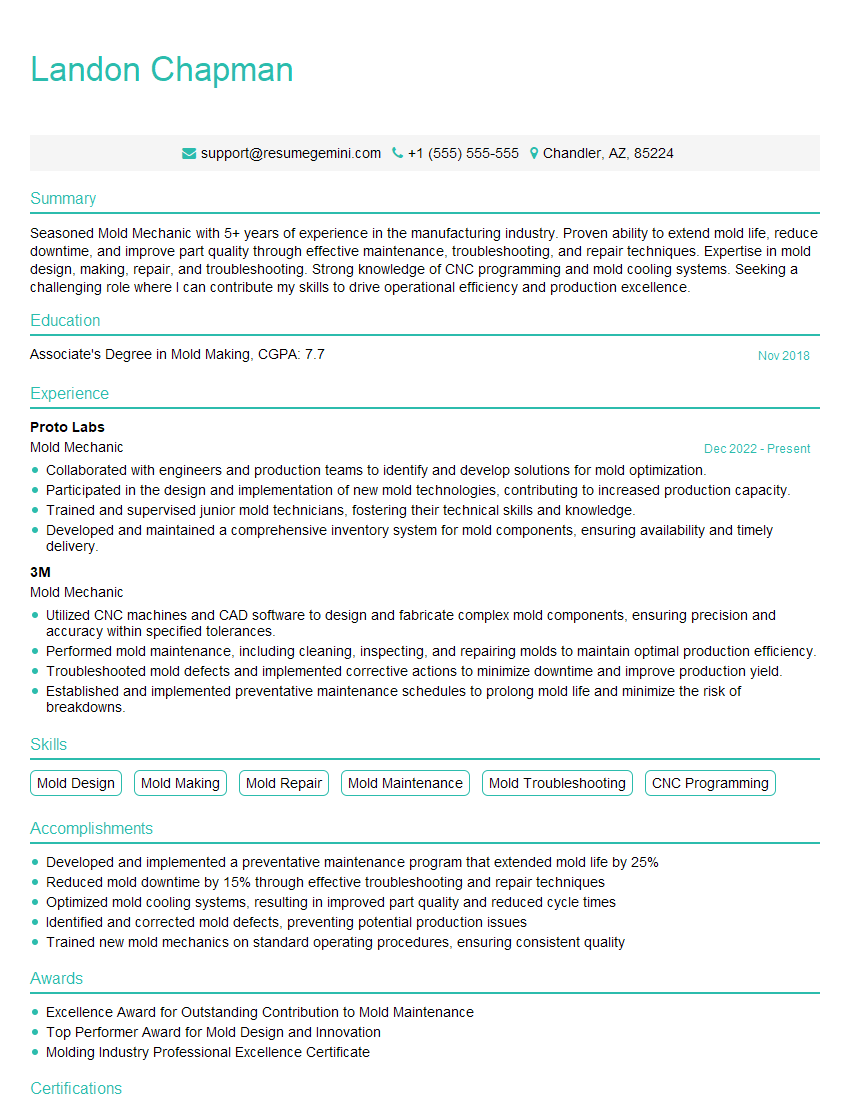

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Mechanic

1. Describe the process of designing and creating a mold?

The process of designing and creating a mold involves several steps:

- Design: The mold design is created using CAD software, taking into account the product’s shape, size, and material properties.

- Mold making: The mold is constructed using various materials such as steel, aluminum, or plastic. The mold’s shape and dimensions are precisely machined to ensure accurate reproduction of the product.

- Mold testing: The mold is tested to ensure it meets the desired specifications and produces products with the correct dimensions and quality.

2. What types of materials are used in mold making, and what are their advantages and disadvantages?

Steel

- Advantages: High durability, strength, and precision.

- Disadvantages: Expensive, prone to corrosion.

Aluminum

- Advantages: Lightweight, cost-effective, easy to machine.

- Disadvantages: Less durable than steel, not suitable for high-volume production.

Plastic

- Advantages: Low cost, lightweight, corrosion-resistant.

- Disadvantages: Less durable, not suitable for high-temperature applications.

3. What are the different mold release agents and their applications?

Mold release agents are used to prevent the molded product from sticking to the mold. Some common types include:

- Silicone-based: General-purpose release agents suitable for a wide range of materials.

- Wax-based: Used for high-temperature applications or where a glossy finish is desired.

- Water-based: Environmentally friendly and cost-effective, but may not be suitable for all materials.

4. What are the common defects that can occur during molding, and how can they be prevented?

Some common molding defects include:

- Flash: Excess material that forms around the edges of the molded product.

- Sinks: Depressions in the surface of the product caused by uneven material flow.

- Bubbles: Air pockets trapped in the material during molding.

- Warping: Distortion of the product due to uneven cooling.

These defects can be prevented through proper mold design, material selection, and process parameters.

5. How do you maintain and calibrate a mold?

Mold maintenance and calibration involve several steps:

- Cleaning: Regularly cleaning the mold to remove any debris or contaminants.

- Inspection: Inspecting the mold for any wear or damage that may affect its performance.

- Calibration: Using precision instruments to ensure the mold’s dimensions and tolerances are accurate.

- Lubrication: Lubricating moving parts of the mold to minimize friction and wear.

6. What are the safety precautions that should be taken when working with molds?

Safety precautions for working with molds include:

- Wear protective gear: Wear gloves, safety glasses, and other protective clothing to prevent injuries.

- Handle chemicals safely: Follow proper procedures for handling and disposing of chemicals used in the molding process.

- Maintain a clean work environment: Keep the work area clean and free of tripping hazards.

- Be aware of moving machinery: Pay attention to moving parts of the molding machine and keep a safe distance.

7. What is the role of a mold mechanic in a manufacturing environment?

The role of a mold mechanic in a manufacturing environment includes:

- Mold design and creation: Designing and producing molds for various products.

- Mold maintenance: Maintaining and calibrating molds to ensure their optimal performance.

- Troubleshooting and repair: Identifying and fixing any issues that arise with molds during production.

- Quality control: Ensuring the quality of molded products meet specifications.

8. What types of software are commonly used in mold making?

Common software used in mold making include:

- CAD software: For designing and modeling molds.

- CAM software: For generating toolpaths for machining molds.

- CAE software: For simulating the molding process and analyzing mold performance.

9. How do you stay updated with the latest advancements in mold making technology?

To stay updated with the latest advancements in mold making technology, I:

- Attend industry conferences and workshops: Participate in events where experts share their knowledge and insights.

- Read trade publications and technical journals: Keep abreast of the latest trends and developments.

- Utilize online resources: Explore websites, forums, and social media platforms for information on new technologies.

- Collaborate with peers and industry professionals: Network and share knowledge with others in the field.

10. What are your career goals and how do you see yourself contributing to our company?

My career goal is to become a highly skilled and experienced mold mechanic. I am eager to contribute my knowledge and skills to your company by:

- Designing and creating high-quality molds: Utilizing my expertise to produce molds that meet exacting specifications.

- Maintaining and optimizing molds: Ensuring molds are in optimal condition to maximize production efficiency.

- Troubleshooting and resolving issues: Identifying and fixing mold problems quickly to minimize downtime.

- Collaborating with colleagues: Working effectively with other team members to achieve common goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mold Mechanic is responsible for the maintenance and repair of molds and dies used in manufacturing processes. Their key job responsibilities include:

1. Mold Maintenance

Inspecting molds and dies for wear and tear, and performing routine maintenance tasks such as cleaning, lubrication, and adjustment.

2. Mold Repair

Diagnosing and repairing damaged molds and dies, using a variety of tools and techniques. This may involve welding, grinding, or machining.

3. Mold Design and Modification

Working with engineers and designers to create new molds or modify existing ones to improve their performance or functionality.

4. Quality Control

Ensuring that molds and dies meet the required quality standards, by inspecting finished products and conducting tests.

Interview Tips

To ace your interview for a Mold Mechanic position, consider the following tips:

1. Research the Industry and Company

Learn about the molding industry, the company’s products and services, and the specific requirements of the role you’re applying for.

2. Highlight Your Technical Skills

Emphasize your understanding of mold design, fabrication, and repair techniques. Provide specific examples of projects you’ve worked on or problems you’ve solved.

3. Demonstrate Problem-Solving Abilities

Mold Mechanics often encounter unexpected issues. Highlight your analytical and troubleshooting skills, and share examples of how you’ve identified and resolved problems in the past.

4. Showcase Your Attention to Detail

Mold Mechanics must be meticulous in their work. Emphasize your strong attention to detail and your ability to work precisely.

5. Prepare Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s molding processes, the team you’d be working with, or the company’s growth plans.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!