Are you gearing up for a career in Plaster Die Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plaster Die Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

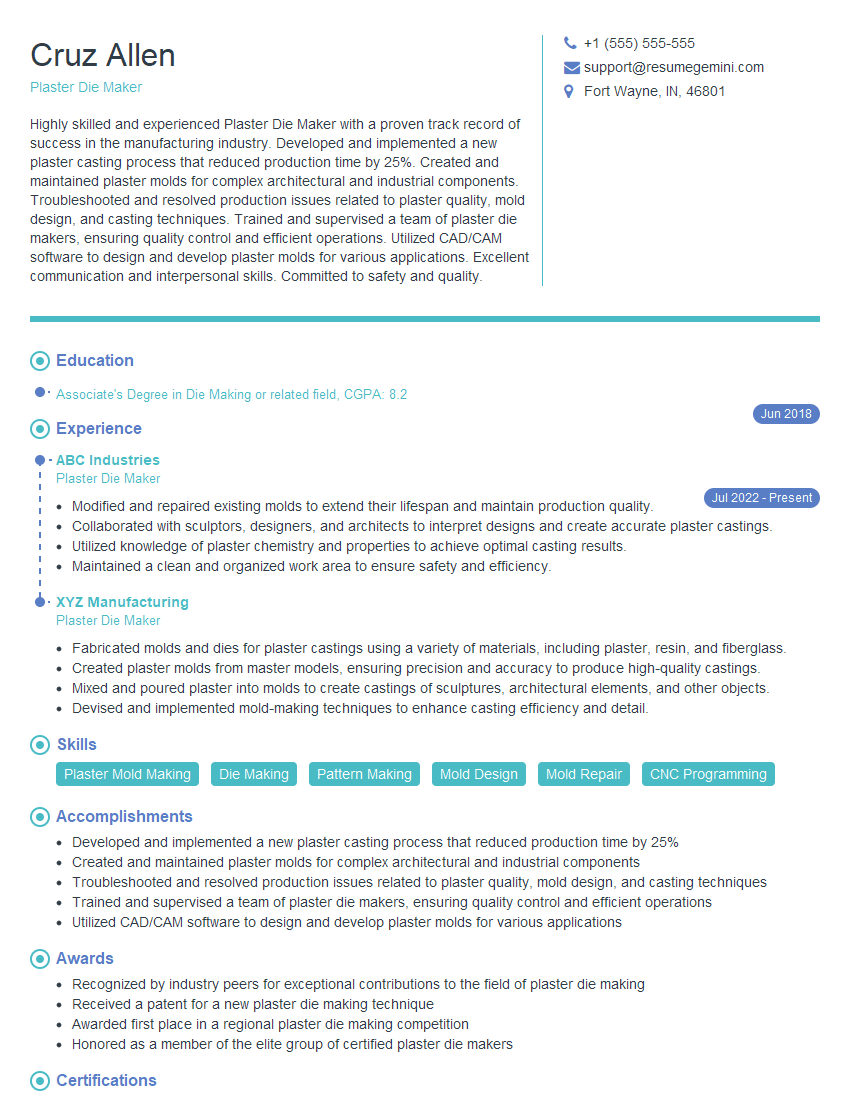

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plaster Die Maker

1. What are the different types of plaster used in die making, and what are their properties?

Here are some common types of plaster used in die making along with their properties:

- Gypsum plaster: Made from calcium sulfate, it is the most common type of plaster used in die making. It is strong, durable, and has a relatively low shrinkage rate.

- Hydrocal plaster: Also known as dental stone, it is a high-strength plaster made from calcium sulfate hemihydrate. It is harder and stronger than gypsum plaster, but it also has a higher shrinkage rate.

- Investment plaster: Used in investment casting, it is a high-temperature plaster made from calcium sulfate and other materials. It can withstand high temperatures and is used to create molds for metal castings.

2. What are the steps involved in making a plaster die?

Creating the master model

- The first step is to create a master model of the object that will be reproduced.

- This can be done using a variety of techniques, such as sculpting, 3D printing, or casting.

Making the mold

- Once the master model is complete, a mold is made around it.

- The mold is typically made from silicone, rubber, or other flexible materials.

Pouring the plaster

- The plaster is then poured into the mold and allowed to set.

- The setting time will vary depending on the type of plaster used.

Removing the die

- Once the plaster has set, the mold is removed, leaving behind the plaster die.

- The die can then be used to create multiple copies of the original object.

3. What are the different factors that can affect the quality of a plaster die?

Here are some factors that can affect the quality of a plaster die:

- The quality of the master model: A poor-quality master model will result in a poor-quality die.

- The type of plaster used: Different types of plaster have different properties, so the choice of plaster will depend on the desired outcome.

- The mold-making process: The mold must be made carefully to ensure that there are no defects that could affect the quality of the die.

- The pouring process: The plaster must be poured carefully to avoid introducing air bubbles or other defects.

- The curing process: The plaster must be allowed to cure properly to achieve its full strength and durability.

4. What are the common problems that can occur during the plaster die making process, and how can they be solved?

Here are some common problems that can occur during the plaster die making process, and how to solve them:

- Air bubbles: Air bubbles can be introduced into the plaster during the pouring process. To avoid this, the plaster should be poured slowly and carefully.

- Defects in the mold: Defects in the mold can cause imperfections in the die. To avoid this, the mold should be inspected carefully before use.

- Improper curing: Improper curing can lead to a weak and brittle die. To ensure proper curing, the plaster should be allowed to cure in a cool, dry environment.

- Cracking: Cracking can occur if the plaster is not properly supported during the curing process. To prevent cracking, the plaster should be supported on all sides.

5. What are some of the applications of plaster dies?

Plaster dies are used in a variety of applications, including:

- Sculpture: Plaster dies are used to create multiple copies of sculptures.

- Ceramics: Plaster dies are used to create molds for ceramic pieces.

- Jewelry: Plaster dies are used to create molds for jewelry pieces.

- Industrial: Plaster dies are used to create molds for industrial products.

6. What are some of the advantages of using plaster dies?

Plaster dies offer a number of advantages, including:

- Low cost: Plaster is a relatively inexpensive material, making it a cost-effective option for die making.

- Easy to use: Plaster is easy to work with, making it a good choice for beginners.

- Versatile: Plaster can be used to create a wide variety of shapes and sizes.

- Durable: Plaster dies are strong and durable, making them suitable for long-term use.

7. What are some of the disadvantages of using plaster dies?

Plaster dies also have some disadvantages, including:

- Brittle: Plaster is a brittle material, so it can be easily damaged if it is not handled carefully.

- Susceptible to moisture: Plaster is susceptible to moisture, so it should not be used in wet or humid environments.

- Limited accuracy: Plaster dies are not as accurate as some other types of dies, so they may not be suitable for applications that require high precision.

8. What are some of the latest developments in plaster die making technology?

There have been a number of recent developments in plaster die making technology, including:

- New materials: New materials have been developed that offer improved strength, durability, and accuracy.

- Automated processes: Automated processes have been developed to improve the efficiency and accuracy of die making.

- 3D printing: 3D printing is being used to create complex and accurate dies.

9. What are some of the future trends in plaster die making?

Some of the future trends in plaster die making include:

- Increased use of new materials: New materials will continue to be developed to improve the performance of plaster dies.

- Further automation: Die making processes will become increasingly automated to improve efficiency and accuracy.

- Integration with 3D printing: 3D printing will be increasingly integrated into die making processes to create complex and accurate dies.

10. What are some of the challenges facing the plaster die making industry?

The plaster die making industry faces a number of challenges, including:

- Competition from other die making technologies: Other die making technologies, such as metal dies and plastic dies, are becoming increasingly popular.

- Rising costs: The cost of materials and labor is rising, making it more difficult for plaster die makers to compete.

- Environmental regulations: Environmental regulations are becoming more stringent, making it more difficult for plaster die makers to dispose of waste materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plaster Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plaster Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plaster Die Makers are responsible for creating and maintaining molds used for casting plaster products. These molds are used to produce a variety of products, including architectural components, decorative pieces, and industrial parts. Key responsibilities include:

1. Fabricating plaster molds

This involves using a variety of materials, including plaster, clay, and sand, to create a mold that will produce a desired product. The mold must be precise and accurate, as it will be used to create multiple castings.

- Creating patterns and models for the molds

- Mixing and pouring plaster into the molds

- Removing the finished castings from the molds

2. Maintaining and repairing plaster molds

Plaster molds can be damaged during use, so it is important to maintain and repair them regularly. This involves cleaning the molds, repairing cracks and chips, and relining the molds with plaster.

- Inspecting molds for damage

- Repairing cracks and chips in molds

- Relining molds with plaster

3. Operating and maintaining equipment

Plaster Die Makers use a variety of equipment in their work, including mixers, grinders, and saws. It is important to operate and maintain this equipment safely and efficiently.

- Operating mixers to mix plaster

- Operating grinders to smooth surfaces

- Operating saws to cut materials

4. Working with other team members

Plaster Die Makers often work with other team members, such as designers, engineers, and production staff. It is important to be able to communicate effectively and work together to achieve common goals.

- Collaborating with designers to create mold designs

- Working with engineers to ensure that molds meet specifications

- Working with production staff to produce castings

Interview Tips

Preparing for an interview for a Plaster Die Maker position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. You should also familiarize yourself with the key responsibilities of the position and the skills and experience required.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Use the STAR method to answer questions

- Focus on your skills and experience

- Be concise and specific

3. Be prepared to talk about your portfolio

As a Plaster Die Maker, you will likely be asked to talk about your portfolio of work. This is a great opportunity to showcase your skills and experience. Be prepared to discuss the different types of molds you have made, the materials you have used, and the techniques you have employed.

- Bring your portfolio to the interview

- Be prepared to discuss your work in detail

- Highlight your strengths and skills

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the company and the position. This shows that you are interested in the opportunity and that you are engaged in the conversation.

- Ask about the company’s culture

- Ask about the team you would be working with

- Ask about the company’s future plans

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plaster Die Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plaster Die Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.