Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Watch Crystal Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

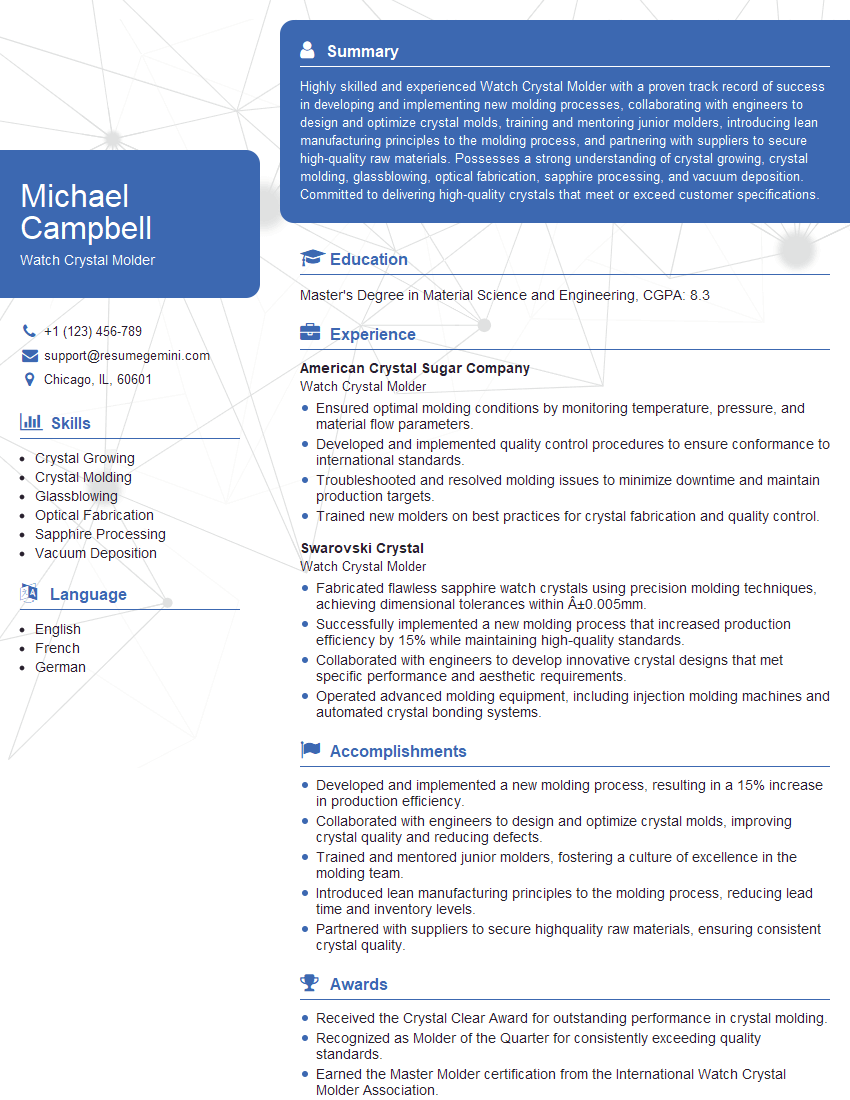

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Watch Crystal Molder

1. Explain the process of crystal molding for watch crystals.

Crystal molding involves several crucial steps to produce watch crystals that meet precise specifications:

- Mold Preparation: High-quality molds are essential for shaping the crystals. They are meticulously crafted from durable materials to withstand repeated use while ensuring dimensional accuracy.

- Material Selection: The choice of material depends on the desired characteristics of the watch crystal, such as scratch resistance, clarity, and durability. Common materials include mineral glass, sapphire, and acrylic.

- Heating and Injection: The selected material is heated to a molten state and injected into the prepared mold under carefully controlled pressure and temperature. This process ensures that the molten material fills the mold cavity completely.

- Pressurization and Cooling: After injection, the mold is pressurized to achieve the desired shape and thickness of the crystal. It is then cooled gradually to avoid thermal stress and ensure proper crystal formation.

- Finishing: Once cooled, the raw crystal is subjected to finishing processes such as grinding, polishing, and anti-reflective coating application. These steps enhance the crystal’s clarity, aesthetics, and functional properties.

2. Describe the different types of watch crystals and their properties.

Mineral Glass

- Commonly used in entry-level and mid-range watches

- Cost-effective and resistant to scratches and wear

- Lower clarity and more prone to breakage than sapphire

Sapphire Crystal

- Highly durable and scratch-resistant, making it ideal for luxury timepieces

- Exceptional clarity and transparency

- More expensive than mineral glass

Acrylic Crystal

- Lightweight and flexible

- Lower scratch resistance and durability compared to mineral and sapphire crystals

- Often used in vintage and casual watches

3. What are the key factors to consider when selecting a crystal for a watch?

Choosing the right crystal for a watch requires careful consideration of the following factors:

- Intended Use: The type of watch (e.g., dress, sports, dive) influences the crystal’s durability, clarity, and anti-reflective properties.

- Material Cost: The material selection significantly impacts the cost of the crystal and watch.

- Scratch Resistance: Sapphire crystals provide superior scratch resistance, while mineral and acrylic crystals are less resistant.

- Clarity: Sapphire crystals offer exceptional clarity, enhancing watch readability and aesthetics.

- Anti-Reflective Properties: Anti-reflective coatings reduce glare and improve dial visibility.

4. How do you ensure the quality of watch crystals during production?

Maintaining the quality of watch crystals throughout production involves rigorous processes:

- Raw Material Inspection: The incoming material is thoroughly inspected to meet the specified quality standards.

- Mold Maintenance: Molds are regularly checked and calibrated to ensure dimensional accuracy and prevent defects.

- Injection Process Monitoring: Parameters such as temperature, pressure, and injection speed are precisely controlled and monitored.

- Annealing and Tempering: Heat treatment processes are applied to relieve internal stresses and enhance the strength and durability of the crystals.

- Post-Production Inspections: Finished crystals are inspected for defects in clarity, surface quality, and dimensions.

5. What are the common challenges faced in watch crystal molding, and how do you overcome them?

Crystal molding presents several challenges that require meticulous attention:

- Air Bubbles: Ensuring a bubble-free injection process is crucial. Degassed materials, vacuum-assisted injection, and proper mold design help prevent bubble formation.

- Dimensional Accuracy: Maintaining precise crystal dimensions is essential. High-quality molds, proper temperature control, and post-production inspection techniques ensure dimensional integrity.

- Scratches and Defects: Careful handling, proper tooling, and surface finishing techniques minimize scratches and defects during molding and post-processing.

6. How do you stay up-to-date with advancements in watch crystal technology?

Remaining current in the field is crucial:

- Industry Events and Conferences: Attending industry events and conferences provides valuable insights into the latest trends and technologies.

- Research and Development: Engaging in ongoing research and development activities helps explore new materials and processes.

- Collaboration with Experts: Building relationships with experts, researchers, and suppliers facilitates knowledge exchange and access to cutting-edge advancements.

7. Explain the role of anti-reflective coatings in watch crystals.

Anti-reflective (AR) coatings play a vital role in watch crystals:

- Reduced Glare: AR coatings minimize light reflection from the crystal’s surface, improving dial visibility, especially in bright conditions.

- Enhanced Clarity: By reducing glare, AR coatings enhance the clarity and contrast of the watch dial, making it easier to read.

8. Describe the process of applying anti-reflective coatings to watch crystals.

Applying AR coatings involves a specialized process:

- Surface Preparation: The crystal surface is meticulously cleaned and prepared to ensure optimal coating adhesion.

- Coating Deposition: Multiple layers of thin film materials are deposited onto the crystal surface using techniques like physical vapor deposition (PVD) or chemical vapor deposition (CVD).

- Annealing: The coated crystal undergoes a heat treatment process to enhance the coating’s durability and performance.

9. What is the lifespan of anti-reflective coatings on watch crystals, and how can you maintain their effectiveness?

The lifespan of AR coatings varies depending on factors such as material, usage, and care:

- Typical Lifespan: AR coatings generally have a lifespan of several years under normal use.

- Maintenance: Regular cleaning with mild soap and water helps maintain the coating’s effectiveness.

10. What are the emerging trends in watch crystal technology?

Watch crystal technology is constantly evolving:

- Scratch-Resistant Coatings: Advancements in coating technologies are leading to improved scratch resistance and durability of crystals.

- Smart Crystals: Integration of electronic components into watch crystals enables new functionalities such as touchscreens and health monitoring.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Watch Crystal Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Watch Crystal Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Watch Crystal Molders are responsible for producing high-quality watch crystals using specialized equipment and techniques. They play a crucial role in the manufacturing process, ensuring that the finished product meets the required specifications.

1. Crystal Molding and Shaping

Operate molding machines to shape and mold crystals according to design specifications.

- Precisely align and load molds into the molding machine.

- Control machine parameters, such as temperature and pressure, to achieve optimal crystal formation.

2. Crystal Annealing and Tempering

Manage annealing and tempering processes to enhance crystal properties.

- Heat crystals to specific temperatures and hold for controlled periods, followed by slow cooling.

- Test and verify crystal properties, such as hardness, durability, and optical clarity.

3. Quality Control and Inspection

Conduct thorough inspections to ensure crystal quality meets standards.

- Visually inspect crystals for defects, such as scratches, bubbles, or distortions.

- Use specialized equipment to measure and analyze crystal dimensions, shape, and optical properties.

4. Equipment Maintenance

Maintain and calibrate molding and inspection equipment to ensure optimal performance.

- Regularly clean and lubricate machinery, replacing worn parts as necessary.

- Monitor equipment performance and troubleshoot issues to prevent downtime.

Interview Tips

To prepare for your interview as a Watch Crystal Molder, it’s essential to understand the key responsibilities and demonstrate your expertise in the following areas:

1. Technical Knowledge

Highlight your understanding of crystal molding techniques, materials, and equipment.

- Describe the different molding processes used to produce watch crystals.

- Explain the role of annealing and tempering in crystal production and how it impacts crystal properties.

2. Quality Assurance

Emphasize your commitment to quality and attention to detail.

- Discuss your experience in conducting visual inspections and using specialized equipment to evaluate crystal quality.

- Provide examples of how you have identified and resolved defects in crystal production.

3. Equipment Expertise

Showcase your knowledge and experience in operating and maintaining molding and inspection equipment.

- Describe your experience with different types of molding machines and how you ensure their optimal performance.

- Explain how you troubleshoot equipment issues and implement preventative maintenance measures.

4. Team Collaboration

Highlight your ability to work effectively in a team environment.

- Describe your experience collaborating with engineers and other production personnel to improve processes and resolve issues.

- Explain how you effectively communicate technical information and contribute to team problem-solving.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Watch Crystal Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!