Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Corrugator Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

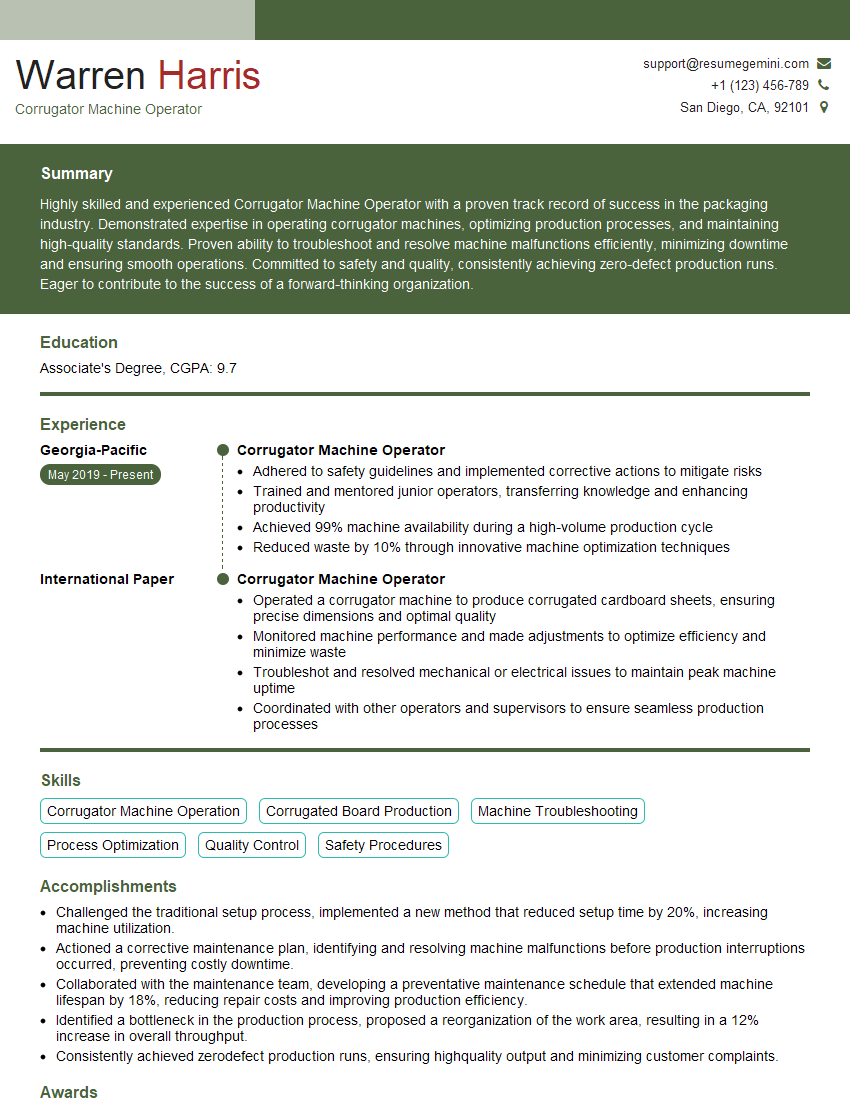

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corrugator Machine Operator

1. Describe the process of setting up a corrugator machine for a new job.

Sample Answer:

- Gather job instructions and order details.

- Calculate roll width and feed speed based on order specifications.

- Set up the corrugator rolls to the required pitch.

- Install the appropriate glue system, depending on the material being used.

- Adjust the machine’s speed and temperature settings.

- Run a test sheet to ensure proper operation before starting the job.

2. How do you troubleshoot common corrugator machine problems, such as blowouts, wrinkles, and delamination?

Sample Answer:

- Blowouts: Check glue application, paper roll temperature, and machine speed.

- Wrinkles: Adjust feed speed, tension, and doctor blade settings.

- Delamination: Inspect glue system, ensure proper bonding temperature, and check for moisture in the paper.

3. What are the safety precautions that you must follow when operating a corrugator machine?

Sample Answer:

- Wear appropriate safety gear, including gloves, goggles, and earplugs.

- Keep hands away from moving parts.

- Lock out the machine before performing maintenance or repairs.

- Be aware of potential hazards, such as hot glue and rotating rolls.

- Follow established safety protocols and report any unsafe conditions.

4. What is the difference between single-facer and double-facer corrugators?

Sample Answer:

- Single-facer: Produces single-wall corrugated board with one layer of fluting between two liners.

- Double-facer: Produces double-wall corrugated board with two layers of fluting and three liners.

5. Can you explain the role of the stacker in a corrugator machine?

Sample Answer:

- Receives and stacks corrugated sheets as they come out of the machine.

- Ensures proper alignment and separation of the sheets.

- Typically controlled by an automated system that coordinates with the machine’s speed.

6. How do you maintain the blade of a corrugator machine to ensure optimal performance?

Sample Answer:

- Sharpen the blade regularly to maintain a smooth cutting surface.

- Inspect the blade for nicks or damage and replace it if necessary.

- Adjust the blade height to ensure proper contact with the paper.

7. Describe the different types of corrugating adhesives and their advantages and disadvantages.

Sample Answer:

- Starch-based: Low cost, biodegradable, but less water-resistant.

- Synthetic resins: Higher strength, moisture resistance, but more expensive.

- Hot-melt adhesives: Quick bonding, strong hold, but require specialized equipment.

8. How do you handle machine downtime during production?

Sample Answer:

- Identify the cause of the downtime and take immediate action to resolve it.

- Communicate with the production team and supervisors to minimize the impact on operations.

- Perform scheduled maintenance and preventative measures to reduce the risk of future downtime.

9. What are some of the quality control measures you perform during corrugator operations?

Sample Answer:

- Inspect the quality of the paper rolls and corrugated sheets.

- Monitor machine settings and make adjustments as needed.

- Test the strength and adhesion of the glue bonds.

- Ensure that the finished product meets customer specifications.

10. How do you continuously improve your skills and knowledge as a Corrugator Machine Operator?

Sample Answer:

- Attend industry conferences and workshops.

- Read technical manuals and articles related to corrugating technology.

- Seek feedback from experienced operators and supervisors.

- Experiment with different machine settings and processes to optimize performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corrugator Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corrugator Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Corrugator Machine Operator is responsible for operating and maintaining a corrugating machine, which produces corrugated cardboard used in packaging.

1. Operating the Corrugator Machine

The operator is responsible for setting up and operating the corrugator machine, ensuring that it runs smoothly and efficiently.

- Loading paper rolls onto the machine

- Adjusting machine settings to produce the desired corrugation pattern

- Monitoring the machine’s operation and making necessary adjustments

2. Maintaining the Corrugator Machine

The operator is also responsible for maintaining the corrugator machine, ensuring that it is in good working condition and preventing breakdowns.

- Cleaning and lubricating the machine

- Inspecting the machine for signs of wear and tear

- Making minor repairs and adjustments

3. Quality Control

The operator is responsible for ensuring that the corrugated cardboard produced by the machine meets quality specifications.

- Visually inspecting the cardboard for defects

- Measuring the cardboard’s thickness and strength

- Making adjustments to the machine to improve the quality of the cardboard

4. Safety

The operator is responsible for following all safety procedures and regulations.

- Wearing appropriate safety gear

- Keeping the work area clean and free of hazards

- Reporting any unsafe conditions to a supervisor

Interview Tips

Following are some tips to help you ace your Corrugator Machine Operator interview:

1. Research the Company and the Position

Before your interview, take some time to research the company you are applying to and the position you are seeking. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer questions

- Be specific and provide examples

- Practice your delivery

3. Be Prepared to Discuss Your Skills and Experience

The interviewer will want to know about your skills and experience as a Corrugator Machine Operator. Be prepared to discuss your experience operating and maintaining corrugating machines, as well as your quality control and safety procedures.

- Highlight your most relevant skills and experience

- Quantify your accomplishments

- Be prepared to answer questions about your work history

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This will show the interviewer that you are respectful of their time.

- Wear clean, pressed clothes

- Arrive on time or early

- Be polite and respectful

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Corrugator Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Corrugator Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.