Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Four Corner Former Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

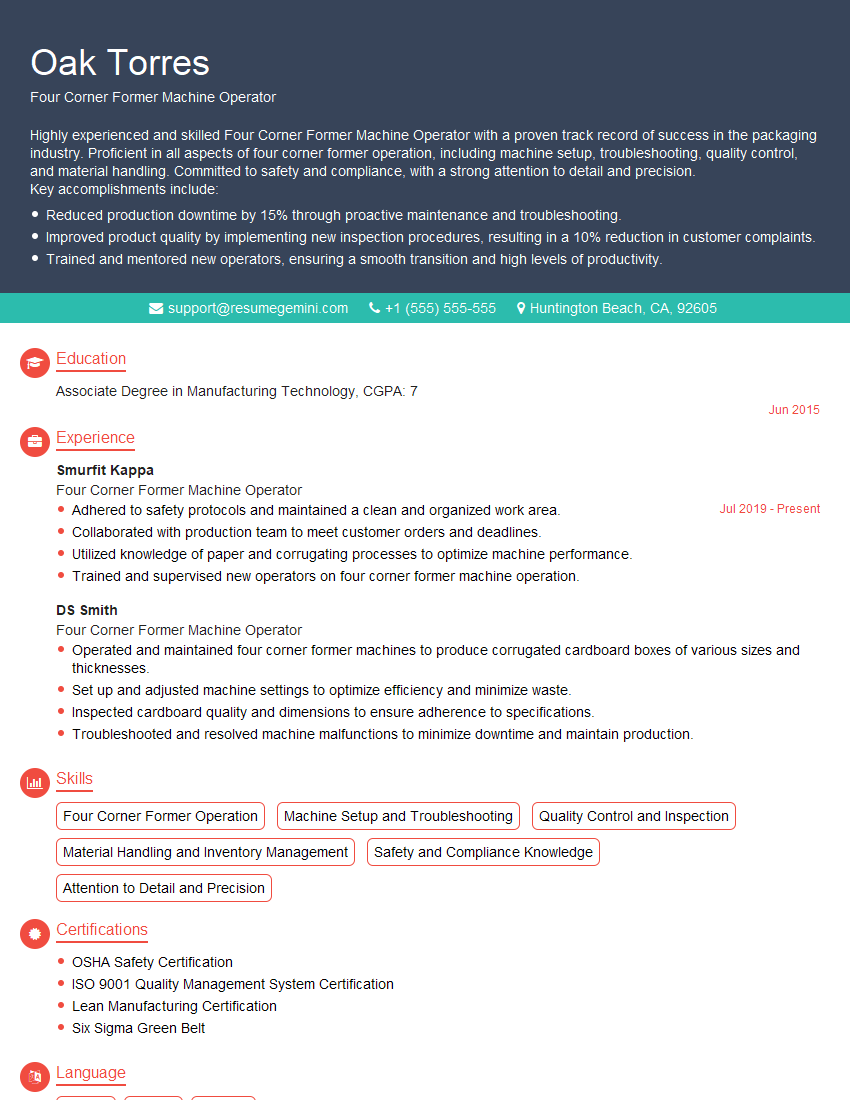

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Four Corner Former Machine Operator

1. Describe the key steps involved in operating a four corner former machine?

- Preparing the machine and materials:

- Loading the paper into the feeder

- Setting up the machine according to the product specifications

- Starting the machine and monitoring the process

- Making adjustments to ensure the desired product quality

- Inspecting the finished product and making any necessary corrections

- Cleaning and maintaining the machine

2. How do you ensure that the corners of the boxes are properly formed and glued?

Ensuring Proper Corner Formation:

- Adjusting the machine settings to the correct specifications

- Using the right type of glue for the material and application

- Applying the glue evenly to the flaps

- Using the right amount of pressure to form the corners

Ensuring Proper Gluing:

- Choosing the right type of glue for the material and application

- Applying the glue evenly to the flaps

- Using the right amount of pressure to bond the flaps

- Inspecting the finished product to ensure proper bonding

3. What are the common issues that can arise during the operation of a four corner former machine, and how do you resolve them?

- Paper jams: Caused by improper paper feeding, incorrect machine settings, or worn-out components. Resolved by clearing the jam, adjusting the settings, or replacing the components.

- Poor corner formation: Caused by incorrect machine settings, dull blades, or insufficient glue. Resolved by adjusting the settings, sharpening the blades, or increasing the glue application.

- Glue spills: Caused by excessive glue application or improper glue adjustment. Resolved by reducing the glue application or adjusting the glue settings.

- Machine breakdowns: Caused by mechanical failures or electrical issues. Resolved by troubleshooting the issue and calling for maintenance or repairs as needed.

4. How do you maintain and troubleshoot a four corner former machine?

- Regular maintenance:

- Cleaning and lubricating the machine

- Inspecting and replacing worn-out parts

- Calibrating the machine

- Troubleshooting:

- Identifying the issue

- Checking for loose connections or damaged components

- Consulting the machine manual or calling for maintenance if necessary

5. How do you ensure that the machine is operating safely and efficiently?

- Following established safety protocols

- Wearing appropriate safety gear

- Maintaining a clean and organized work area

- Monitoring the machine’s performance and making adjustments as needed

- Reporting any safety concerns or malfunctions to the supervisor

6. How do you handle variations in paper quality and thickness?

- Adjusting the machine settings to accommodate the different material properties

- Using different types of glue or adhesives for different materials

- Modifying the machine speed or pressure to optimize the forming process

- Inspecting the finished product to ensure proper quality and making adjustments as needed

7. How do you minimize waste and optimize production?

- Properly setting up the machine to avoid errors and reduce rejects

- Using the correct amount of materials to avoid waste

- Regularly maintaining the machine to prevent breakdowns and minimize downtime

- Training operators to follow best practices and improve efficiency

8. How do you stay updated on the latest advancements in four corner former machine technology?

- Attending industry events and trade shows

- Reading technical articles and whitepapers

- Consulting with equipment manufacturers and vendors

- Participating in online forums and discussion groups

9. How do you maintain a positive and collaborative work environment within a production team?

- Communicating clearly and effectively

- Respecting different perspectives and opinions

- Providing support and assistance to team members

- Recognizing and appreciating contributions

- Working together to solve problems and achieve common goals

10. Why are you interested in joining our company as a Four Corner Former Machine Operator?

This question is an opportunity for you to express your interest in the specific company and role. Research the company’s website, industry reputation, and any relevant news or articles. You can also highlight your skills, experience, and how they align with the company’s needs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Four Corner Former Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Four Corner Former Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Four Corner Former Machine Operators play a crucial role in the manufacturing process by operating and maintaining machines that form and shape paperboard into specific shapes.

1. Machine Operation

Operate four corner former machines to shape and form paperboard according to specified dimensions and tolerances.

- Set up and adjust machine settings based on production requirements.

- Monitor machine operation and make necessary adjustments to optimize performance and maintain quality standards.

2. Production Management

Maintain a consistent production flow by monitoring paperboard quality, identifying and resolving any issues promptly.

- Inspect finished products to ensure they meet specifications and customer requirements.

- Maintain accurate production records and report any deviations or problems to supervisors.

3. Machine Maintenance

Perform regular maintenance and troubleshooting to keep machines in optimal working condition.

- Clean and lubricate machine components to prevent breakdowns and extend their lifespan.

- Identify and repair minor mechanical issues, escalate major problems to maintenance personnel.

4. Safety Compliance

Adhere to all safety regulations and procedures to ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE) and follow safety protocols.

- Identify and report potential safety hazards to supervisors.

Interview Preparation Tips

To ace the interview for a Four Corner Former Machine Operator position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and industry standing. Research the specific role to understand its responsibilities and the company’s expectations.

- Visit the company website, LinkedIn page, and industry news sources.

- Read the job description carefully and highlight your relevant skills and experience.

2. Highlight Your Technical Expertise

Emphasize your proficiency in operating and maintaining Four Corner Former machines. Mention your experience in troubleshooting, setting up, and adjusting machine settings.

- Quantify your achievements using specific metrics, such as production output or machine uptime.

- Demonstrate your understanding of paperboard properties and how they relate to machine operation.

3. Showcase Your Production Management Skills

Convey your ability to manage production efficiently and maintain quality standards. Discuss your experience in monitoring paperboard quality, identifying issues, and taking corrective actions.

- Provide examples of how you have improved production processes or resolved quality problems.

- Highlight your ability to work independently and as part of a team to achieve production targets.

4. Emphasize Safety and Compliance

Stress your commitment to safety and compliance. Describe your understanding of safety regulations and your experience in maintaining a safe work environment.

- Explain your knowledge of PPE requirements and your adherence to safety protocols.

- Discuss your ability to identify and report potential safety hazards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Four Corner Former Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!