Are you gearing up for an interview for a Paper Plate Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Paper Plate Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

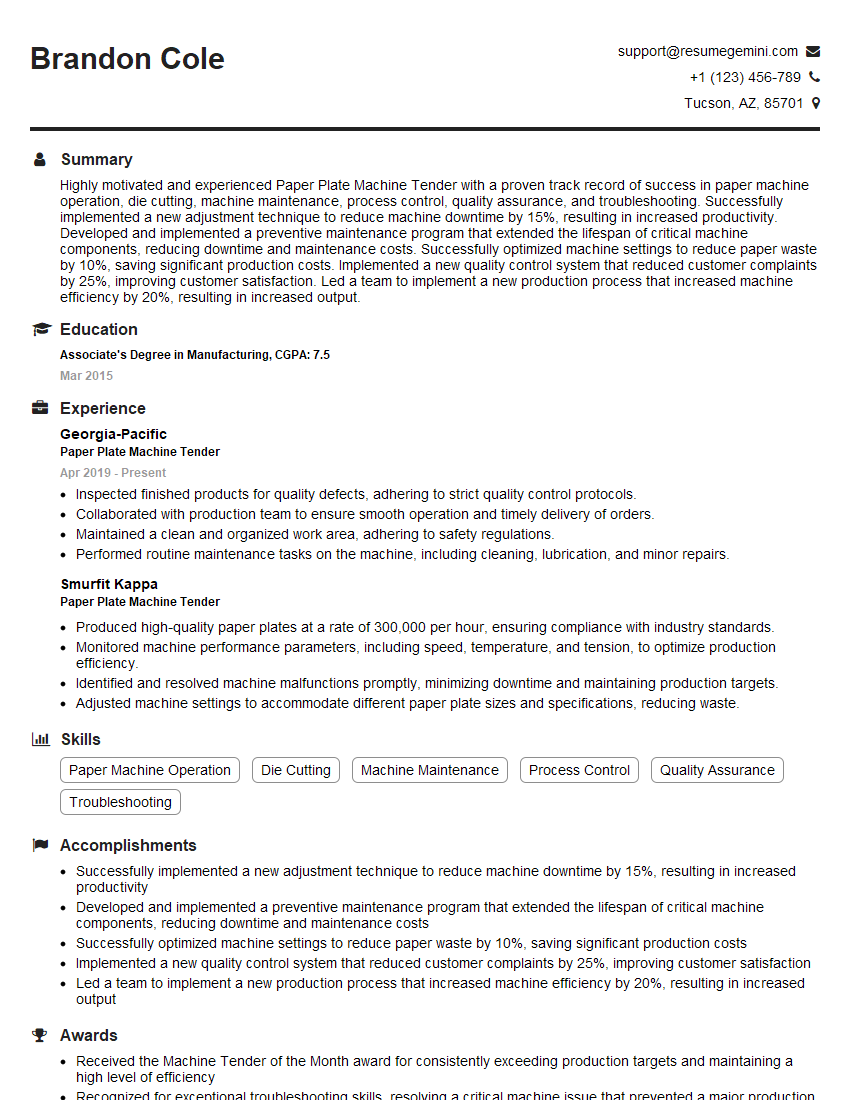

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Plate Machine Tender

1. How do you ensure the quality of paper plates produced on the machine?

To ensure the quality of paper plates produced on the machine, I follow a comprehensive quality control process that includes the following steps:

- Raw material inspection: I inspect the incoming paperboard to ensure it meets the required specifications for thickness, smoothness, and moisture content.

- Machine setup: I carefully set up the machine according to the specifications for the desired plate size, shape, and design.

- Regular machine monitoring: During operation, I continuously monitor the machine’s performance, including temperature, pressure, and speed, to ensure optimal conditions.

- In-process quality checks: I conduct regular visual inspections of the plates as they are being produced, checking for defects such as cracks, creases, or uneven edges.

- Final product inspection: Once the plates are formed, I perform a thorough final inspection to ensure they meet the required quality standards before packaging and shipping.

2. What are some common troubleshooting techniques you use when the paper plate machine encounters problems?

Mechanical Issues:

- Paper jams: I inspect the paper path for obstructions, adjust tension settings, and lubricate components as needed.

- Molding issues: I check the mold for wear or damage, adjust pressure settings, and ensure proper lubrication.

- Heating element failures: I inspect the heating elements, replace faulty ones, and calibrate temperature settings.

Electrical Issues:

- Motor problems: I troubleshoot electrical connections, check for loose wires, and replace defective motors.

- Sensor malfunctions: I diagnose sensor failures, clean or replace sensors, and recalibrate as necessary.

3. How do you handle high-volume production targets while maintaining accuracy and efficiency?

To handle high-volume production targets while maintaining accuracy and efficiency, I employ several strategies:

- Machine optimization: I regularly fine-tune the machine’s settings to maximize production speed without compromising quality.

- Preventive maintenance: I adhere to a rigorous preventive maintenance schedule to minimize downtime and ensure the machine is operating at peak performance.

- Efficient work practices: I streamline my workflow by organizing materials, minimizing material handling, and implementing automation where possible.

- Teamwork and communication: I collaborate effectively with other team members to ensure smooth material flow and timely product delivery.

4. What are the safety precautions you take when working with the paper plate machine?

I prioritize safety by adhering to the following precautions:

- Machine guarding: I ensure all machine guards are in place and functioning properly.

- PPE utilization: I wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Lockout/tagout procedures: I follow established lockout/tagout procedures to prevent accidental machine startup during maintenance or repairs.

- Emergency response training: I am trained in emergency response procedures and know how to operate safety equipment.

- Risk assessment and hazard identification: I conduct regular risk assessments to identify potential hazards and implement control measures.

5. How do you manage the waste generated by the paper plate production process?

To manage waste effectively, I follow these practices:

- Waste segregation: I separate recyclable waste (paperboard scraps) from general waste.

- Recycling programs: I participate in recycling programs to reduce the environmental impact.

- Waste minimization: I optimize machine settings and minimize material waste through efficient production practices.

- Compliance with regulations: I adhere to all applicable environmental regulations and guidelines.

6. How do you stay updated with the latest advancements in paper plate manufacturing technology?

To stay current with advancements, I engage in the following activities:

- Industry conferences and trade shows: I attend industry events to learn about new technologies and best practices.

- Technical publications and journals: I read industry publications and journals to keep abreast of research and development.

- Online resources and webinars: I utilize online resources and participate in webinars to expand my knowledge.

- Collaboration with suppliers and experts: I consult with suppliers and industry experts to gain insights into emerging technologies.

7. How do you manage multiple production orders with varying specifications simultaneously?

To manage multiple orders effectively, I follow these steps:

- Order prioritization: I prioritize orders based on deadlines and customer requirements.

- Production scheduling: I create a detailed production schedule to optimize machine utilization and minimize downtime.

- Material management: I track inventory levels and coordinate with the supply chain to ensure timely material availability.

- Communication: I communicate with customers and other team members to provide updates and address any concerns.

8. What is your experience with different types of paper plate machines, and how do you adapt to new models?

I have experience with various types of paper plate machines, including rotary die-cutters, flatbed die-cutters, and forming machines. When adapting to a new model, I:

- Technical manuals and training: I thoroughly study technical manuals and attend training sessions to familiarize myself with the machine’s features and operation.

- Observations and experimentation: I observe experienced operators and experiment with different settings to optimize machine performance.

- Troubleshooting: I proactively identify potential issues and develop troubleshooting strategies to minimize downtime.

9. How do you ensure product consistency and meet customer specifications?

To ensure product consistency and meet customer specifications, I implement the following measures:

- Standard operating procedures (SOPs): I adhere to established SOPs to maintain uniformity in production processes.

- Quality control checks: I conduct regular quality checks throughout the production process to identify and rectify any deviations.

- Customer feedback: I actively gather customer feedback and incorporate their suggestions into production improvements.

- Continuous improvement: I participate in continuous improvement initiatives to identify areas for optimization and enhance product quality.

10. How do you handle high-pressure situations and meet tight deadlines?

In high-pressure situations and when faced with tight deadlines, I remain calm and focused by:

- Prioritizing tasks: I assess the urgency of tasks and prioritize them accordingly.

- Time management: I effectively manage my time and utilize resources efficiently.

- Communication: I communicate effectively with colleagues and supervisors to ensure everyone is informed and working towards the same goal.

- Stress management: I practice stress management techniques to maintain composure under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Plate Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Plate Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Plate Machine Tenders are responsible for operating and maintaining paper plate machines. They ensure that the machines are running efficiently and producing high-quality paper plates.

1. Preparing the machine for operation

This involves checking the machine for any damage or wear and tear, making sure that all of the components are properly lubricated, and setting up the machine for the desired plate size and thickness.

2. Operating the machine

This involves loading the paper roll onto the machine, starting the machine, and monitoring the operation of the machine. The Paper Plate Machine Tender must make sure that the paper is being fed into the machine correctly, that the plates are being cut to the correct size and thickness, and that the plates are being stacked properly.

3. Maintaining the machine

This involves cleaning the machine regularly, checking the machine for any problems, and making any necessary repairs. The Paper Plate Machine Tender must also keep a log of all maintenance activities.

4. Troubleshooting

If the machine breaks down, the Paper Plate Machine Tender must be able to troubleshoot the problem and make the necessary repairs. This may involve replacing a part, adjusting a setting, or calling a maintenance technician.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are some tips to help you ace your interview for a Paper Plate Machine Tender position:

1. Research the company

Before your interview, take some time to research the company you are applying to. This will help you understand the company’s culture, values, and goals. You can also use this information to tailor your answers to the interviewer’s questions.

2. Be prepared to talk about your experience

The interviewer will likely ask you about your experience operating and maintaining paper plate machines. Be prepared to talk about your skills and knowledge in this area. You can also highlight any specific accomplishments you have achieved in your previous roles.

3. Be prepared to answer questions about your troubleshooting skills

The interviewer may also ask you about your troubleshooting skills. Be prepared to talk about a time when you had to troubleshoot a problem on a paper plate machine. Explain how you diagnosed the problem and what steps you took to resolve it.

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the position and the company. Ask questions about the company’s culture, the training program, and the opportunities for advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paper Plate Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!