Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spiral Tube Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

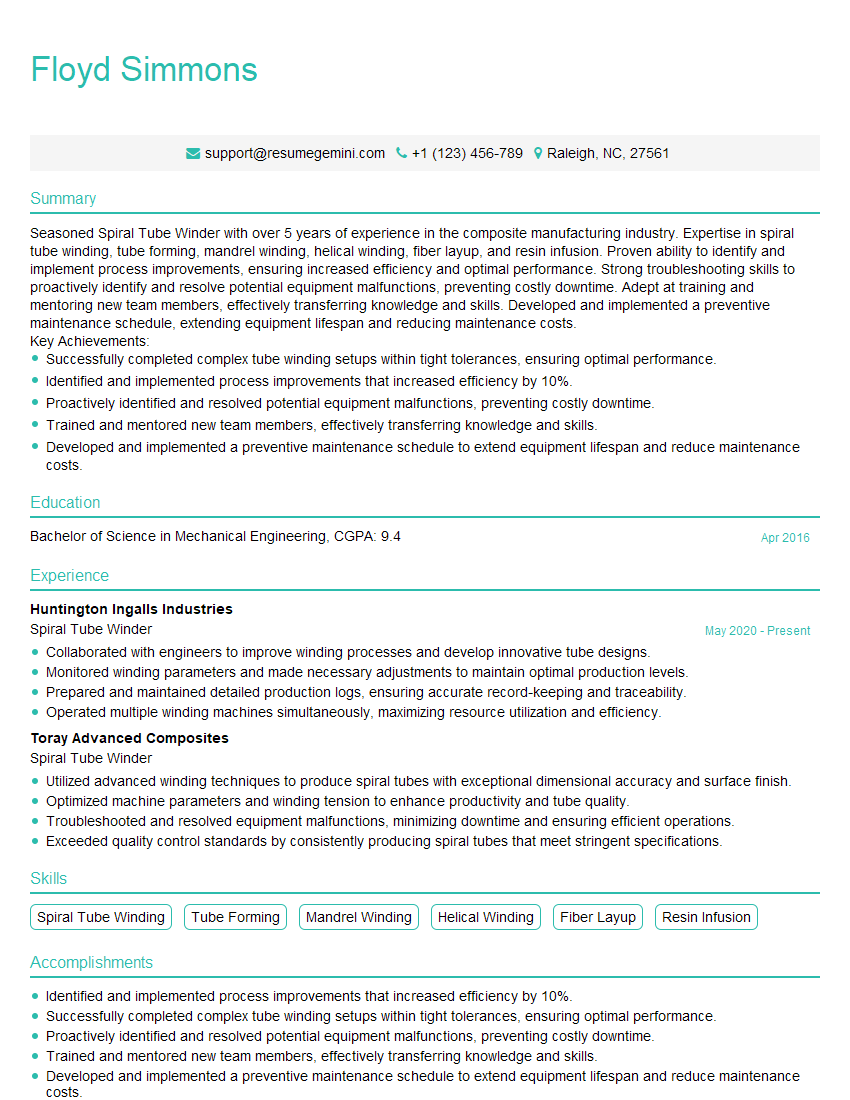

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spiral Tube Winder

1. Can you explain the winding principles used in spiral tube winding?

- Spiral tube winding involves forming a helical shape with a continuous strip of material.

- The winding process requires precise control of the strip’s tension, alignment, and positioning to ensure a uniform and tightly wound tube.

- Various winding techniques can be used, including mandrel winding, centerless winding, and tension winding, each with its advantages and applications.

2. Describe the different types of spiral tubes manufactured.

Types of Spiral Tubes

- Round Spiral Tubes: Circular cross-section, used in various industries, including packaging, construction, and automotive.

- Square Spiral Tubes: Square or rectangular cross-section, often used for structural applications, such as furniture and support frames.

- Oval Spiral Tubes: Elliptical or oval cross-section, commonly used in packaging and display.

Applications of Spiral Tubes

- Packaging: Protective cases for products, mailing tubes, display stands.

- Construction: Structural components, support frames, railings.

- Automotive: Fuel and brake lines, exhaust systems.

3. How do you ensure the dimensional accuracy and consistency of spiral tubes?

- Precise control of winding parameters, such as strip tension, mandrel speed, and winding angle.

- Regular calibration and maintenance of winding equipment to minimize deviations.

- Inspection and testing throughout the winding process, including automated systems and manual checks.

- Use of high-quality materials with consistent tolerances.

4. What factors influence the strength and durability of spiral tubes?

- Material properties: Strength, elasticity, and resistance to environmental factors.

- Tube dimensions: Wall thickness, diameter, and length.

- Winding angle and overlap: Affects tube rigidity and strength.

- Manufacturing process: Consistency of winding, proper tension control, and post-processing treatments.

5. How do you optimize the winding process for different materials?

- Understand the material’s properties and characteristics.

- Adjust winding parameters, such as tension, speed, and angle, to suit the specific material.

- Use appropriate mandrels and tooling designed for the material being wound.

- Consider post-processing treatments, such as heat treatment or coating, to enhance material properties.

6. Describe the troubleshooting techniques you employ when encountering production problems in spiral tube winding.

- Identify the problem by observing the tube and winding process.

- Check the winding parameters and equipment to ensure they are within specifications.

- Inspect the material for defects or inconsistencies.

- Make necessary adjustments to the process, such as adjusting tension, speed, or mandrel.

- Consult with colleagues or superiors for additional support and expertise.

7. How do you maintain and calibrate the winding equipment used in spiral tube production?

- Regular cleaning and inspection of equipment to prevent dirt, debris, or damage.

- Lubrication of moving parts to ensure smooth operation.

- Calibration of sensors and gauges to ensure accurate measurements and control.

- Verification of winding parameters and settings to maintain consistency.

- Following manufacturer’s instructions and recommended maintenance schedules.

8. What safety precautions do you observe when operating spiral tube winding machines?

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Ensuring the machine is properly grounded and all electrical connections are secure.

- Keeping the work area clean and organized, free from tripping hazards.

- Never operating the machine with unguarded moving parts.

- Following established safety protocols and procedures.

9. How do you stay updated on the latest advancements and best practices in spiral tube winding?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Networking with professionals in the field.

- Participating in online forums and discussion groups.

- Seeking training and certification programs.

10. Can you provide examples of projects where you successfully applied your skills in spiral tube winding?

- Describe a project where you developed and implemented a new winding technique to improve tube strength.

- Mention a project where you optimized the winding process for a specific material, resulting in reduced production costs.

- Share an example of a project where you solved a complex production issue related to spiral tube winding.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spiral Tube Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spiral Tube Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for a Spiral Tube Winder

A Spiral Tube Winder is responsible for the operation and maintenance of spiral tube winding machines, which are used to produce spiral tubes for various industrial applications. Key job responsibilities include:

1. Machine Operation

Setting up and operating spiral tube winding machines to produce tubes of specified dimensions and materials.

- Adjusting machine settings, such as winding speed, tension, and temperature.

- Monitoring machine operation and making necessary adjustments to ensure optimal performance.

- Troubleshooting and resolving machine malfunctions promptly.

2. Quality Control

Inspecting and verifying the quality of produced spiral tubes, ensuring they meet specifications.

- Conducting dimensional and visual inspections to ensure tubes meet required tolerances.

- Performing tensile and other tests to evaluate tube strength and durability.

- Maintaining records of inspection results and submitting them for review.

3. Maintenance and Repair

Performing routine maintenance and repairs on spiral tube winding machines to ensure their proper functioning.

- Cleaning and lubricating machine components.

- Replacing worn or damaged parts.

- Conducting preventive maintenance to minimize downtime.

4. Process Improvement

Identifying and implementing process improvements to enhance productivity and reduce waste.

- Analyzing production data and identifying areas for optimization.

- Suggesting and implementing changes to machine setup or process parameters.

- Documenting process improvements and sharing them with colleagues.

Interview Preparation Tips for a Spiral Tube Winder Position

To ace an interview for a Spiral Tube Winder position, candidates should be well-prepared and present themselves professionally. Here are some interview preparation tips:

1. Research the Company and Position

Take the time to research the company and the specific role you are applying for. This will help you understand the company culture and the expectations for the position.

- Visit the company website to learn about their products, services, and mission.

- Read articles or news releases about the company to stay informed about their industry and recent developments.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Prepare thoughtful and concise answers to these questions beforehand.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experience.

- Practice answering questions out loud to improve your delivery and confidence.

3. Highlight Relevant Skills and Experience

Make sure to emphasize your relevant skills and experience during the interview. This includes any experience with spiral tube winding machines, quality control, maintenance, and process improvement.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Be prepared to discuss how your skills and experience align with the requirements of the position.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Prepare questions about the company culture, the challenges and opportunities of the position, and the company’s future plans.

- Avoid asking questions that are easily answered by reading the job description or company website.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you are serious about the position.

- Choose an outfit that is clean, pressed, and appropriate for the company culture.

- Plan your route to the interview location in advance to avoid being late.

By following these interview preparation tips, you can increase your chances of acing your interview for a Spiral Tube Winder position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spiral Tube Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.