Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Auto Tire Recapper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Auto Tire Recapper so you can tailor your answers to impress potential employers.

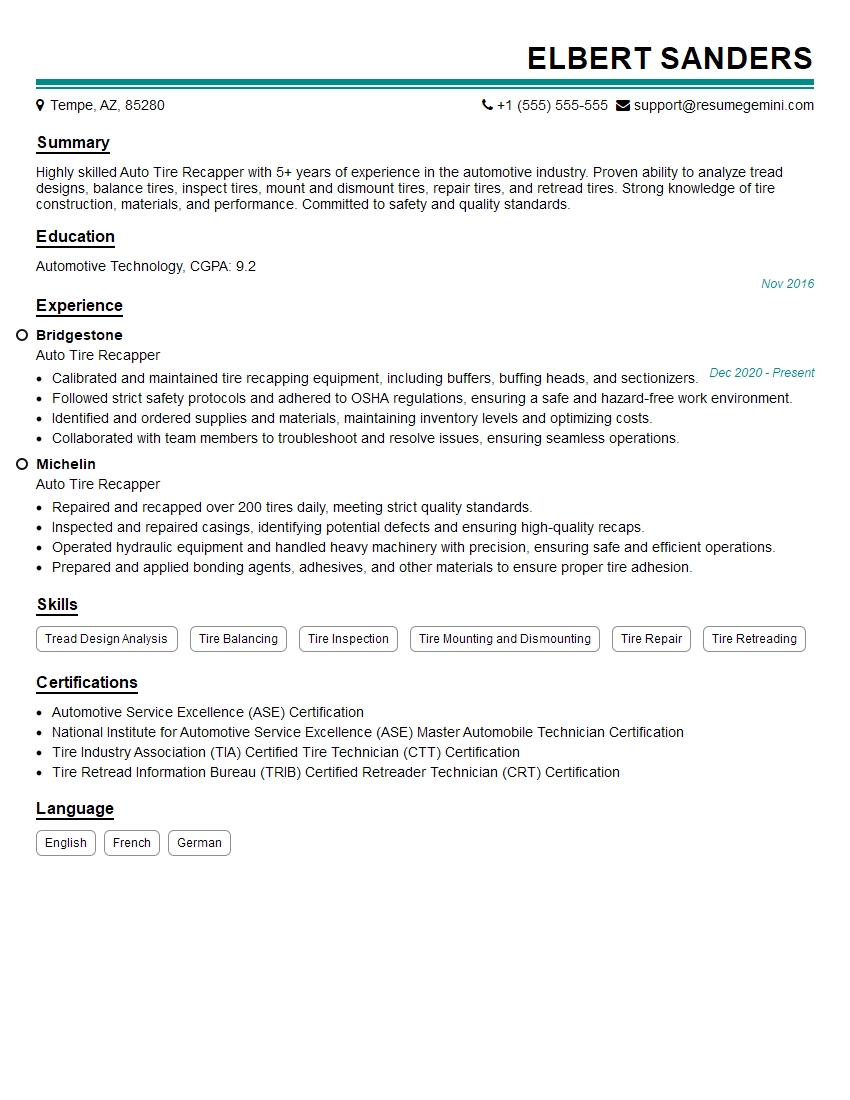

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Auto Tire Recapper

1. Tell me about your experience in retreading tires?

In my previous role as an Auto Tire Recapper, I was responsible for the entire retreading process, from inspecting the tires to applying the new tread. I have a deep understanding of the different types of retreading materials and techniques, and I am proficient in using all of the necessary equipment.

2. What are the key steps involved in retreading a tire?

Pre-inspection

- Inspect the tire for any damage that may affect the retreading process.

- Check the tire’s sidewall for any cracks or bulges.

- Remove the old tread from the tire.

Buffing

- Buff the tire’s casing to remove any remaining old tread or debris.

- This creates a smooth surface for the new tread to adhere to.

Cementing

- Apply a cement to the buffed tire casing.

- This cement helps to bond the new tread to the casing.

Treading

- Apply the new tread to the tire casing.

- Use a mold to shape the tread and ensure that it is properly bonded to the casing.

Curing

- Cure the tire in an oven to activate the cement and bond the tread to the casing.

- This process takes several hours.

Final inspection

- Inspect the retreaded tire for any defects.

- Ensure that the tire meets all safety standards.

3. What are the different types of retreading materials and techniques?

There are two main types of retreading materials: hot and cold. Hot retreading involves using a mold and heat to bond the new tread to the tire casing. Cold retreading, on the other hand, uses a chemical bonding agent to adhere the new tread to the casing.

There are also different techniques for retreading tires, depending on the type of tire and the desired results. Some of the most common techniques include:

- Conventional retreading: This is the most common type of retreading, and it involves removing the old tread from the tire and applying a new tread.

- Pre-cure retreading: This type of retreading involves using a pre-cured tread that is bonded to the tire casing using heat and pressure.

- Mold cure retreading: This type of retreading involves using a mold to shape the new tread and bond it to the tire casing. This technique is often used for retreading truck tires.

4. What are the advantages of retreading tires?

- Cost savings: Retreading tires is significantly less expensive than buying new tires.

- Environmental benefits: Retreading tires helps to reduce waste and conserve natural resources.

- Improved performance: Retreaded tires can perform as well as new tires, and they can even be used in demanding applications.

- Increased safety: Retreading tires can help to improve traction and handling, which can lead to increased safety.

5. What are the challenges of retreading tires?

- Quality control: It is important to ensure that retreaded tires are of high quality and meet all safety standards.

- Equipment costs: The equipment required for retreading tires can be expensive.

- Training: Retreading tires requires specialized training and experience.

6. What are the latest trends in retreading technology?

- The use of new materials: New materials, such as nano-composites, are being developed to improve the performance and durability of retreaded tires.

- The development of new techniques: New techniques, such as laser etching, are being developed to improve the quality and efficiency of retreading.

- The use of automation: Automation is being used to improve the efficiency and accuracy of retreading.

7. What are the safety considerations when retreading tires?

- Proper training: Retreading tires requires specialized training and experience.

- Use of proper equipment: The equipment used for retreading tires must be properly maintained and calibrated.

- Quality control: Retreaded tires must be inspected carefully to ensure that they meet all safety standards.

- Proper storage: Retreaded tires must be stored properly to prevent damage.

8. What is the future of the retreading industry?

The retreading industry is expected to grow in the coming years, as more and more businesses and consumers become aware of the benefits of retreading tires. The development of new materials and techniques is also expected to lead to improvements in the quality and performance of retreaded tires.

9. What is your favorite part of the retreading process?

I enjoy the challenge of taking a damaged tire and restoring it to like-new condition. I also appreciate the fact that retreading tires is a sustainable practice that helps to reduce waste and conserve natural resources.

10. What are your career goals?

I am passionate about the retreading industry, and I hope to continue to grow my skills and knowledge in this field. I would like to eventually become a manager or supervisor in a retreading facility.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Auto Tire Recapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Auto Tire Recapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Auto Tire Recapers are responsible for recapping tires, which involves removing the old tread from a used tire and replacing it with a new one. This process helps extend the life of tires and reduce waste.

1. Inspecting Tires

Inspect used tires to determine if they are suitable for recapping. This includes checking for damage, wear, and other defects.

2. Preparing Tires

Prepare tires for recapping by removing the old tread and cleaning the casing. This is typically done using a tire buffing machine.

3. Applying New Tread

Apply new tread to the prepared tire casing using a tire building machine. This involves fitting the new tread onto the casing and applying adhesive.

4. Curing Tires

Place recapped tires in a curing chamber to heat and pressurize them. This process helps vulcanize the new tread and bond it to the casing.

5. Inspecting Finished Tires

Inspect finished tires to ensure they meet quality standards. This includes checking for proper tread depth, balance, and any other defects.

6. Maintaining Equipment

Maintain and calibrate tire recapping equipment to ensure optimal performance and safety.

7. Following Safety Procedures

Follow all safety procedures when operating tire recapping equipment and handling tires.

Interview Tips

Preparing for an Auto Tire Recapper interview can help you make a great impression and increase your chances of getting the job. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and what they’re looking for in a candidate.

2. Practice Your Answers

Think about the common interview questions you’re likely to be asked and prepare your answers ahead of time. Practice answering these questions out loud to build confidence and ensure your answers are clear and concise.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the job you’re applying for. Use specific examples to demonstrate your abilities and how they can benefit the company.

4. Be Enthusiastic and Professional

Show the interviewer that you’re enthusiastic about the position and the company. Be polite, professional, and respectful throughout the interview.

5. Ask Questions

Asking thoughtful questions at the end of the interview shows the interviewer that you’re engaged and interested in the position. It also gives you an opportunity to clarify any details or ask about the company’s culture.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Auto Tire Recapper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Auto Tire Recapper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.