Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Retread Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Retread Technician so you can tailor your answers to impress potential employers.

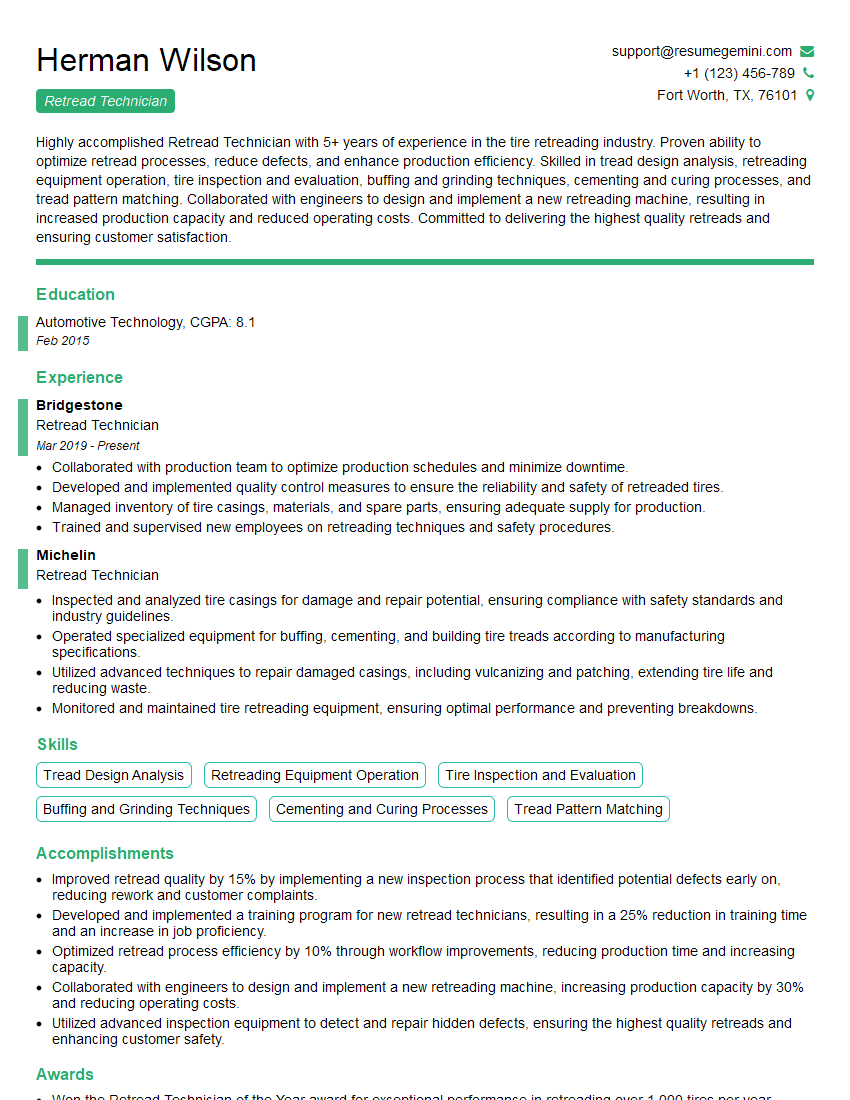

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retread Technician

1. What are the key steps involved in the tire retreading process?

In the tire retreading process, tires are inspected, buffed, prepared, and built-up. Inspection involves checking for any damages or defects. Buffing is done to remove the old tread, while preparation involves cleaning and sealing the casing. Building-up refers to the application of new tread and sidewall compounds.

2. How do you handle different types of tire damage, such as punctures, sidewall cuts, and tread separations?

Punctures

- Identify the puncture location and remove any foreign objects.

- Buff the area around the puncture to create a clean surface.

- Apply a patch or plug to seal the puncture.

Sidewall Cuts

- Inspect the extent of the cut to determine if it is repairable.

- Grind the edges of the cut and clean the area.

- Apply a sidewall repair patch.

Tread Separations

- Inspect the separation to determine the severity and cause.

- Remove any loose or damaged tread.

- Buff the area and apply a bonding agent.

- Install a new tread section.

3. What are the safety precautions that you observe while working with tire retreading equipment?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure that the equipment is properly maintained and calibrated.

- Follow manufacturer’s instructions for operating the equipment.

- Keep the work area clean and free of hazards.

- Be aware of the potential for high temperatures and use caution when handling hot equipment or materials.

4. How do you inspect a tire casing to determine if it is suitable for retreading?

- Check the overall condition of the casing for any major damage or defects.

- Inspect the bead area for any cracks or bulges.

- Examine the sidewalls for any cuts, gouges, or abrasions.

- Check the tread area for any excessive wear or unevenness.

- Measure the casing’s depth to ensure it meets the minimum requirements for retreading.

5. What are the different methods of applying new tread to a tire casing?

- Mold Cure Method: Involves placing the casing in a mold and injecting uncured rubber, which is then heated and cured.

- Pre-Cure Tread Method: Involves applying pre-cured tread strips to the casing using an adhesive.

- Extrusion Method: Involves extruding hot rubber onto the casing and shaping it using a die.

6. How do you ensure proper bonding between the new tread and the casing?

- Clean and prepare the casing surface to remove any contaminants or imperfections.

- Apply a bonding agent to the casing to enhance adhesion.

- Use the appropriate curing method and temperature to ensure a strong bond.

7. What are the different types of tire retread compounds available, and how do you select the appropriate compound for a specific application?

Types of Tire Retread Compounds:

- Natural Rubber

- Synthetic Rubber

- Butyl Rubber

- Ethylene-Propylene-Diene Monomer (EPDM)

Selection of Compound:

- Consider the intended use of the tire (e.g., on-road, off-road, heavy-duty).

- Match the compound’s properties (e.g., durability, traction, fuel efficiency) to the application.

- Follow the manufacturer’s recommendations for specific compound usage.

8. How do you maintain and calibrate the equipment used in tire retreading?

- Follow the manufacturer’s maintenance schedule for each piece of equipment.

- Inspect equipment regularly for any signs of wear or damage.

- Calibrate equipment according to the manufacturer’s specifications to ensure accurate measurements.

- Keep records of maintenance and calibration to track equipment performance.

9. What are the environmental regulations that apply to tire retreading operations?

- Proper disposal of waste materials, including scrap tires and solvents.

- Compliance with air quality standards to minimize emissions from retreading processes.

- Adherence to local and national environmental regulations related to hazardous materials.

10. How do you stay updated on the latest advancements in tire retreading techniques and materials?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Consult with equipment manufacturers and materials suppliers.

- Participate in online forums and discussion groups.

11. Can you describe a challenging tire retreading project you have worked on and how you overcame the challenges?

I once encountered a tire with severe sidewall damage that required extensive repairs. The challenge was to ensure a strong and safe bond between the new sidewall section and the existing casing. I carefully prepared the surfaces, applied a specialized bonding agent, and used a combination of heating and pressure to create a durable connection.

12. What is the difference between hot and cold retreading methods?

Hot Retreading

- Involves heating the uncured rubber and the tire casing.

- Provides a strong bond between the new tread and the casing.

Cold Retreading

- Uses pre-cured tread strips that are bonded to the casing using an adhesive.

- Faster and more convenient than hot retreading.

13. What are the key factors to consider when selecting a tire retreading supplier?

- Reputation and experience in the industry.

- Quality of materials and workmanship.

- Range of retreading services offered.

- Cost and turnaround time.

- Compliance with industry standards and regulations.

14. How do you ensure the quality of retreaded tires?

- Thorough inspection of tires before, during, and after the retreading process.

- Use of high-quality materials and equipment.

- Adherence to strict quality control standards.

- Regular testing and monitoring of retreaded tires.

15. What are the benefits of tire retreading for businesses and consumers?

Businesses:

- Reduced operating costs through extended tire life.

- Improved fleet efficiency and sustainability.

- Lower environmental impact.

Consumers:

- More affordable tire options.

- Improved safety and performance from retreaded tires that meet industry standards.

- Contribution to environmental conservation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retread Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retread Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Retread Technicians are very significant personnel in the tire industry. Their primary job is to restore worn-out tires to a usable condition. They perform various tasks, such as inspecting tires, repairing damaged areas, and applying new tread. Here are some of the key job responsibilities of a Retread Technician:

1. Tire Inspection

Retread Technicians thoroughly inspect tires to identify areas that need repair or retreading.

- Inspect tires for damage, such as punctures, cuts, and bulges.

- Determine the extent of the damage and whether it can be repaired.

2. Tire Repair

Retread Technicians repair damaged areas on tires to restore their integrity.

- Repair punctures and cuts using specialized tools and materials.

- Repair or replace damaged sidewalls, treads, and belts.

3. Tire Retreading

Retread Technicians apply a new layer of tread to worn-out tires to extend their lifespan.

- Prepare the tire for retreading by removing the old tread.

- Apply a new layer of tread using specialized equipment.

- Cure the tire under controlled conditions to ensure proper bonding of the new tread.

4. Quality Control

Retread Technicians ensure that the tires they repair or retread meet safety and performance standards.

- Inspect the finished tires to ensure they are free of defects.

- Perform quality control tests to verify the performance of the retreaded tires.

Interview Tips

Preparing for an interview can be daunting, but it’s essential to increase your chances of success. Here are some tips to help you ace your interview for a Retread Technician position:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Retread Technician position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role. You can find information on the company’s website, social media pages, and industry publications.

- Review the company’s mission, vision, and values.

- Identify the key responsibilities and qualifications for the Retread Technician position.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice answering these questions in a clear and concise manner.

- Prepare a brief introduction that highlights your relevant skills and experience.

- Craft a compelling answer to explain why you are interested in the position and the company.

3. Highlight Your Skills and Experience

During the interview, it’s important to highlight your skills and experience that are relevant to the Retread Technician position. Use specific examples to demonstrate your abilities in tire inspection, repair, and retreading.

- Quantify your accomplishments whenever possible to showcase your impact.

- Be prepared to discuss your experience with specific tire repair and retreading equipment.

4. Be Enthusiastic and Professional

First impressions matter, so it’s important to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and maintain eye contact with the interviewer. Your positive attitude and demeanor can make a lasting impression.

- Smile, make eye contact, and greet the interviewer with a firm handshake.

- Be confident and articulate in your responses, but also be respectful and listen attentively.

Next Step:

Now that you’re armed with the knowledge of Retread Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Retread Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini