Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tire Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

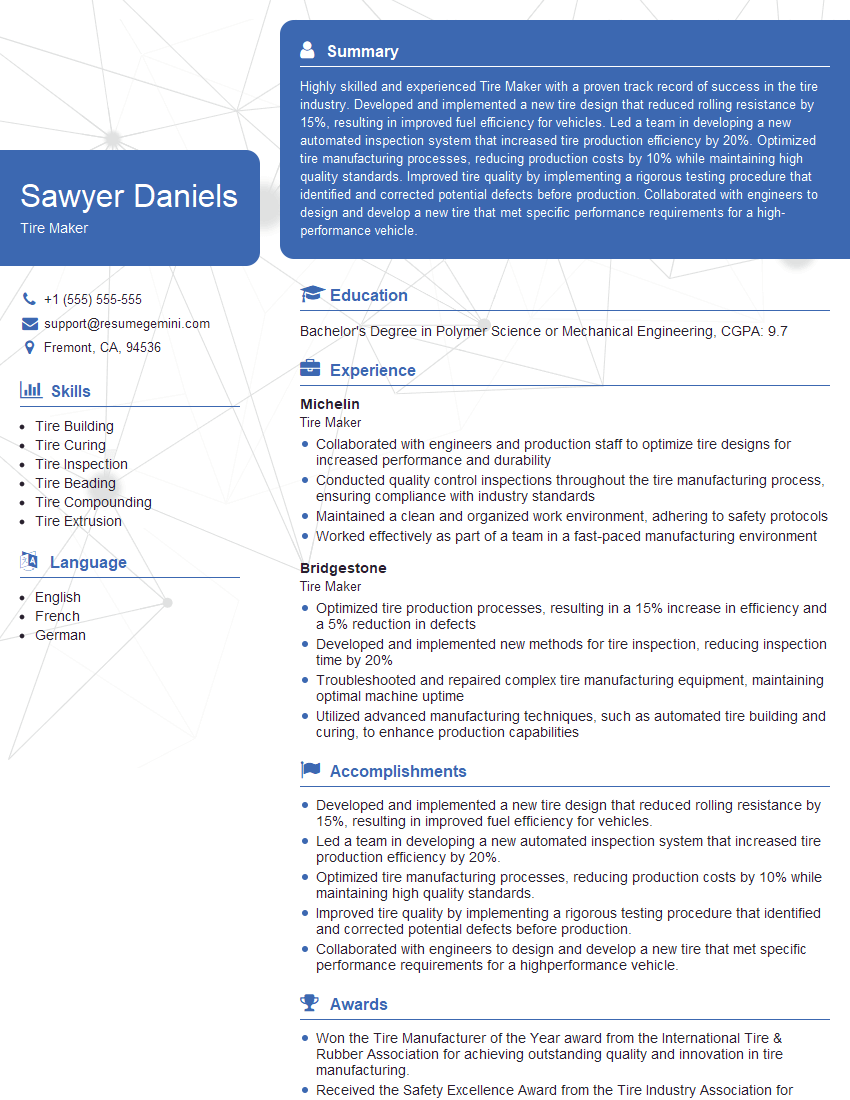

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Maker

1. Explain the different types of tire construction and their advantages and disadvantages?

- Bias-ply tires: Constructed with layers of fabric cords arranged at an angle to the direction of travel.

- Advantages: Strong, durable, and good traction on rough terrain.

- Disadvantages: Rough ride, limited speed capability, and prone to sidewall flex.

- Radial tires: Constructed with layers of fabric cords arranged perpendicular to the direction of travel.

- Advantages: Smooth ride, improved fuel efficiency, and better cornering stability.

- Disadvantages: Less durable than bias-ply tires and more prone to punctures.

- Belted tires: Similar to radial tires but with an additional belt of steel or aramid fibers beneath the tread.

- Advantages: Enhanced stability, improved handling, and reduced rolling resistance.

- Disadvantages: Slightly more expensive than non-belted tires.

2. Describe the process of tire compounding and its importance in tire performance?

- Tire compounding: Mixing of raw materials (rubber, carbon black, silica, etc.) to create the tire’s compound.

- Importance:

- Determines tire properties such as traction, rolling resistance, wear resistance, and durability.

- Optimizing the compound is crucial for balancing performance, safety, and longevity.

3. Explain the different methods of tire curing and how they affect the final product?

- Hot curing: Heating the tire in a mold under pressure.

- Advantages: Creates a stronger bond between the rubber and the reinforcing cords.

- Disadvantages: Long process, higher energy consumption.

- Cold curing: Curing the tire at room temperature using chemical accelerators.

- Advantages: Faster process, lower energy consumption.

- Disadvantages: May result in a weaker bond between the rubber and the cords.

4. Discuss the significance of tire balancing and alignment in vehicle performance?

- Tire balancing: Ensuring that the weight of the tire and wheel assembly is evenly distributed.

- Significance: Reduces vibrations, improves ride quality, and extends tire life.

- Tire alignment: Adjusting the angles of the tires to ensure they make proper contact with the road.

- Significance: Optimizes handling, improves fuel efficiency, and reduces uneven tire wear.

5. Describe the different types of tire defects and how they can be detected?

- Tread defects: Cuts, punctures, bulges, and uneven wear.

- Detection: Visual inspection, tread depth measurement.

- Sidewall defects: Cracks, cuts, and bulges.

- Detection: Visual inspection, hand inspection for bulges.

- Bead defects: Deformations or damage to the bead area.

- Detection: Visual inspection, air leakage test.

6. Explain the role of tire pressure monitoring systems (TPMS) in vehicle safety?

- TPMS: Wireless systems that monitor tire pressure and alert the driver to underinflation or overinflation.

- Role: Improves vehicle handling, reduces the risk of blowouts, and extends tire life.

7. Describe the latest advancements in tire technology and their impact on the industry?

- Run-flat tires: Designed to maintain mobility even after a puncture or loss of inflation.

- Low rolling resistance tires: Reduce energy consumption and improve fuel efficiency.

- Self-healing tires: Incorporated with sealant materials that automatically repair small punctures.

- Smart tires: Equipped with sensors to monitor tire health and performance.

8. Discuss the environmental regulations and challenges related to tire production?

- Regulations: Restrictions on the use of certain hazardous chemicals, recycling requirements.

- Challenges: Minimizing waste, energy consumption, and greenhouse gas emissions.

9. Explain the different quality control measures implemented in tire manufacturing?

- Raw material inspection: Ensuring the quality of rubber, cords, and other materials.

- In-process inspections: Monitoring production steps to detect defects early.

- Final product testing: Performance evaluations, durability tests, and safety checks.

- Statistical process control: Using statistical methods to identify and address variations in production.

10. Describe the key research and development areas in the tire industry?

- Advanced materials: Developing new rubber compounds with improved performance and durability.

- Tire design optimization: Using simulations and modeling to optimize tread patterns and sidewall designs.

- Smart tires and sensors: Integrating technologies to enhance tire health monitoring and safety.

- Sustainable manufacturing: Exploring eco-friendly processes, alternative materials, and tire recycling techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Makers, also known as Tire Builders, play a crucial role in the manufacturing process of tires. They are responsible for assembling and molding raw materials into high-quality tires that meet industry standards.

1. Tire Assembly

Tire Makers meticulously assemble various tire components, including the tread, sidewalls, bead wires, and inner liners. They adhere to precise specifications and use specialized equipment to ensure proper fit and alignment.

2. Tire Building

Using sophisticated machinery, Tire Makers build tires by placing the assembled components into a mold. They apply pressure and heat to shape and cure the tire, resulting in a durable and functional product.

3. Quality Control

Tire Makers are responsible for maintaining high standards of quality. They perform inspections throughout the assembly and building process to identify and rectify any defects. They adhere to quality assurance protocols and ensure that tires meet specifications.

4. Machine Maintenance

Tire Makers are often involved in the maintenance and upkeep of tire-building machinery. They understand the operation of these machines and can diagnose and resolve minor issues to minimize downtime and maintain efficient production.

Interview Preparation Tips

To ace the Tire Maker interview, candidates should thoroughly prepare by researching the industry, practicing their answers, and demonstrating their skills and qualifications.

1. Research the Industry and Company

Gain insights into the tire industry, major players, and the company you’re applying to. Familiarize yourself with their products, manufacturing processes, and market trends. This will demonstrate your interest and enthusiasm for the field.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your responses. Practice articulating your skills, experience, and why you’re a suitable candidate for the role. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers effectively.

3. Highlight Relevant Skills and Experience

Emphasize your technical skills and knowledge in tire assembly, building, and quality control. Showcase your ability to work independently and as part of a team, as well as your attention to detail and commitment to quality. Mention any previous experience in manufacturing or a related field.

4. Prepare for Technical Questions

Expect questions about tire manufacturing processes, machinery, and quality standards. Be prepared to explain the steps involved in tire assembly and building, as well as your understanding of tire properties and performance. Research industry terminology and stay up-to-date on technological advancements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tire Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!