Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tire Recapper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tire Recapper so you can tailor your answers to impress potential employers.

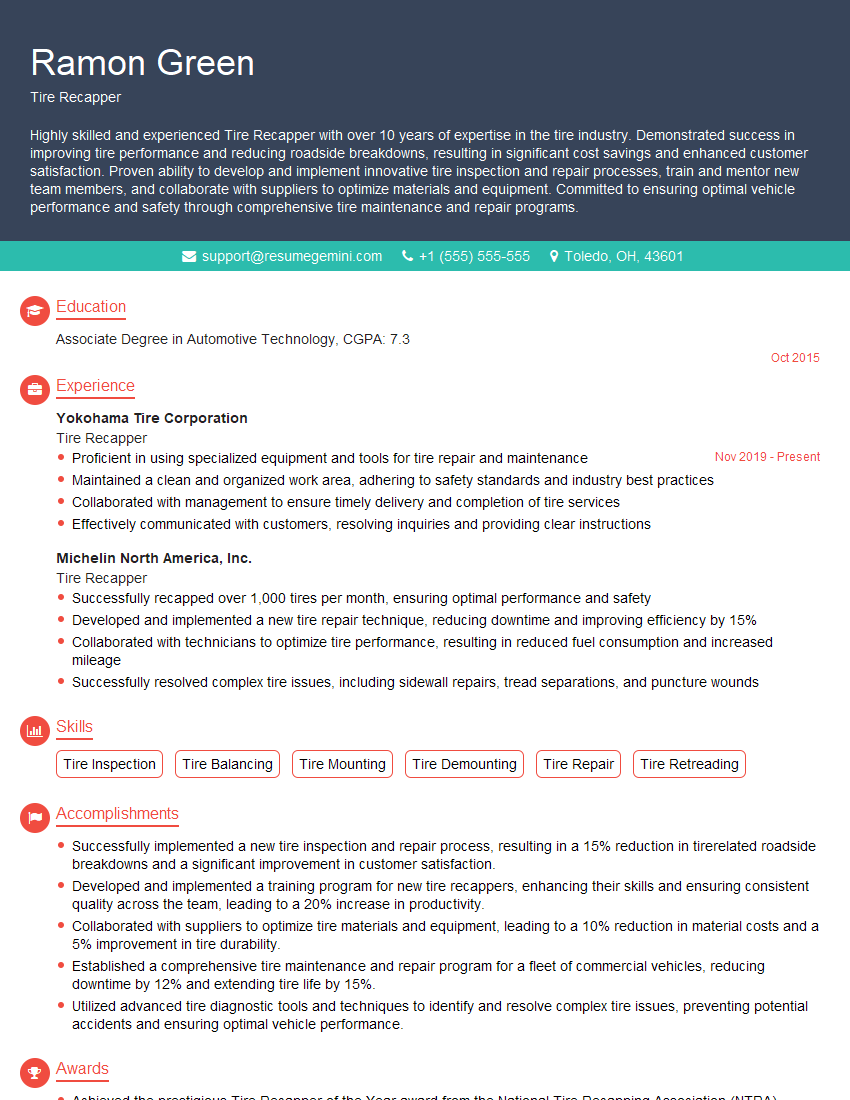

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Recapper

1. Describe the steps involved in recapping a tire?

The steps involved in recapping a tire include:

- Inspecting the tire to assess its condition and suitability for recapping.

- Removing the old tread from the tire casing using a buffing machine.

- Applying a new layer of tread rubber to the casing using a tread extruder.

- Vulcanizing the new tread to the casing using heat and pressure.

- Trimming and finishing the recapped tire.

2. What are the different types of tread patterns available for tire recapping?

Tread patterns for on-road applications

- Ribbed tread: Provides good traction and handling.

- Lug tread: Designed for off-road use, offers excellent grip on loose surfaces.

- Block tread: Combines the features of ribbed and lug tread, provides good traction on both on- and off-road.

Tread patterns for off-road applications

- Tractor tread: Designed for agricultural equipment, provides good traction in soft soil.

- Earthmover tread: Designed for heavy equipment, provides excellent traction on rough terrain.

- Mining tread: Designed for use in mines, can handle extreme conditions.

3. What factors should be considered when selecting a tread pattern for tire recapping?

- Type of vehicle and its intended use.

- Road conditions and terrain where the vehicle will be operated.

- Tire size and load capacity.

- Cost and availability of different tread patterns.

4. Describe the different types of tire casings that can be recapped.

- Radial casings: Have cords that run radially from bead to bead, providing good stability and handling.

- Bias-ply casings: Have cords that run diagonally from bead to bead, offering increased strength and durability.

- Steel-belted casings: Have a layer of steel belts under the tread, providing improved puncture resistance and durability.

5. What are the advantages and disadvantages of recapping tires?

Advantages of tire recapping

- Cost savings: Recapping tires is typically less expensive than purchasing new tires.

- Environmental benefits: Recapping tires reduces waste and conserves resources.

- Improved performance: Recapped tires can provide comparable performance to new tires.

Disadvantages of tire recapping

- Not all tires are suitable for recapping.

- Recapped tires may not have the same lifespan as new tires.

- The quality of recapping can vary depending on the remanufacturer.

6. What are some common defects that can occur during tire recapping?

- Tread separation: Occurs when the new tread detaches from the casing.

- Bead damage: Can occur during the removal of the old tire from the rim.

- Improper curing: Can result in weak or brittle tread.

- Uneven wear: Can occur if the tire is not properly balanced or aligned.

7. How can the quality of tire recapping be ensured?

- Selecting a reputable remanufacturer.

- Inspecting the tire casing carefully before recapping.

- Following the manufacturer’s instructions for recapping.

- Properly curing the tire.

- Balancing and aligning the tire after recapping.

8. What are the safety precautions that should be taken when working with tires?

- Always wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Use proper tools and equipment for tire handling and recapping.

- Never attempt to mount or dismount a tire from a rim that is not properly secured.

- Be aware of potential hazards, such as exposed wires and sharp edges.

9. What is your experience with tire recapping equipment?

In my previous role as a Tire Recapper, I was responsible for operating and maintaining a variety of tire recapping equipment, including:

- Tire buffing machines

- Tread extruders

- Vulcanizing presses

- Tire balancing and alignment machines

I am proficient in using these machines to safely and efficiently recap tires.

10. Are there any new technologies or trends in the tire recapping industry that you are aware of?

- The use of advanced materials, such as nanocomposites, to improve the performance and durability of recapped tires.

- The development of automated tire recapping systems to increase efficiency and reduce labor costs.

- The use of 3D printing to create custom tread patterns for specific applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Recapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Recapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Recapers are responsible for refurbishing and reusing tires, reducing waste and conserving natural resources. Their primary tasks include:

1. Inspecting Damaged Tires

Assess the extent of tire damage, determining if recapping is feasible or if the tire should be replaced.

- Inspecting treads, sidewalls, and bead areas for punctures, cuts, or other damage.

- Examining tires for signs of uneven wear or structural issues.

2. Removing Old Tread and Preparing Tires

Strip off the damaged or worn tread using specialized equipment, leaving behind a suitable base for recapping.

- Operating buffing machines to remove old tread.

- Inspecting tires for any remaining damage or imperfections.

3. Applying New Rubber

Apply a new layer of rubber to the prepared tire, ensuring proper adhesion and balance.

- Using specialized equipment to apply uncured rubber to the tire.

- Ensuring proper curing conditions for optimal adhesion and durability.

4. Molding and Shaping Tires

Shape the new rubber into the desired tread pattern and dimensions using molds or shaping equipment.

- Positioning tires in molds or on shaping machinery.

- Adjusting molds or equipment to achieve the correct tread pattern and dimensions.

5. Curing Tires

Subject recapped tires to controlled heat and pressure processes to cure the rubber fully.

- Monitoring tire temperature and pressure during curing.

- Ensuring proper curing time and conditions for optimal performance.

6. Inspecting Finished Tires

Perform quality control checks on recapped tires, ensuring they meet industry standards and customer specifications.

- Inspecting tires for uniformity, balance, and tread depth.

- Testing tires for leaks or other defects.

Interview Tips

To ace an interview for a Tire Recapper position, consider the following tips:

1. Research the Company and Industry

Learn about the company’s tire recapping practices, their target market, and their reputation in the industry. This will demonstrate your interest and willingness to align with their values.

2. Highlight Relevant Skills and Experience

Emphasize your expertise in tire inspection, tread removal, rubber application, molding, curing, and quality control. Provide specific examples that showcase your proficiency in these areas.

3. Demonstrate Safety Awareness

Tire recapping involves working with heavy machinery and hazardous materials. Emphasize your commitment to safety protocols, including proper handling techniques, personal protective equipment, and emergency procedures.

4. Show Attention to Detail

Tire recapping requires precision and a keen eye for detail. Highlight your ability to closely examine tires for damage, identify potential issues, and ensure the quality of the finished product.

5. Prepare Questions

Asking thoughtful questions about the company’s recapping process, quality standards, and commitment to sustainability demonstrates your engagement and interest in the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tire Recapper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.