Are you gearing up for an interview for a Abrasive Mixer Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Abrasive Mixer Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

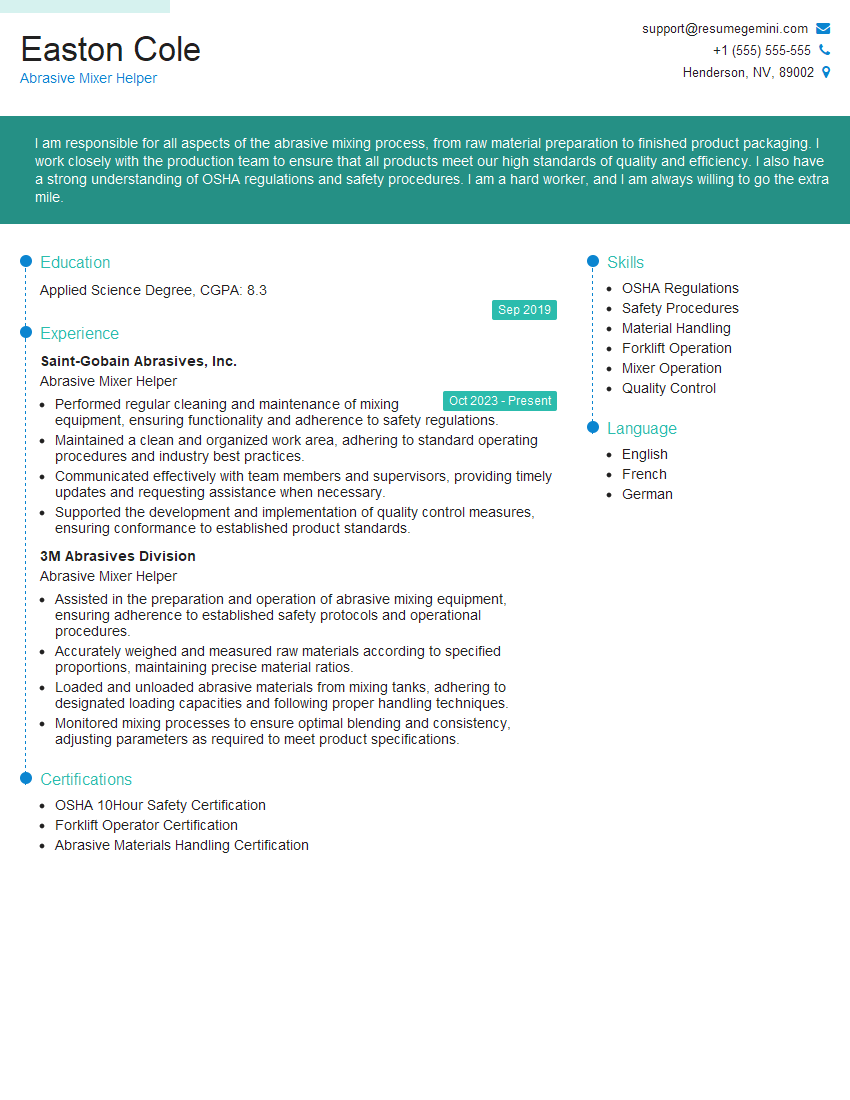

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Abrasive Mixer Helper

1. Describe the steps involved in mixing abrasive materials?

The steps involved in mixing abrasive materials include:

- Identify the abrasive materials to be mixed

- Calculate the proportions of each material needed

- Measure out the correct proportions of each material

- Mix the materials together until they are evenly distributed

- Check the mixture to ensure it meets the desired specifications

2. What are the different types of abrasive materials?

The different types of abrasive materials include:

- Natural abrasives (e.g., sand, pumice)

- Synthetic abrasives (e.g., aluminum oxide, silicon carbide)

- Bonded abrasives (e.g., grinding wheels, sanding belts)

3. What safety precautions should be taken when working with abrasive materials?

The safety precautions that should be taken when working with abrasive materials include:

- Wear appropriate personal protective equipment (e.g., gloves, eye protection, respirator)

- Use the equipment in a well-ventilated area

- Avoid contact with skin and eyes

- Dispose of used abrasive materials properly

4. What are the different uses of abrasive materials?

Abrasive materials are used in a variety of applications, including:

- Grinding

- Sanding

- Polishing

- Lapping

- Honing

5. What are the different types of mixing equipment used for abrasive materials?

The different types of mixing equipment used for abrasive materials include:

- Paddle mixers

- Ribbon blenders

- Screw conveyors

- Air classifiers

6. What are the factors that affect the quality of the abrasive mixture?

The factors that affect the quality of the abrasive mixture include:

- The type of abrasive materials used

- The proportions of each material

- The mixing time

- The temperature of the mixture

- The presence of moisture

7. How do you ensure that the abrasive mixture meets the desired specifications?

To ensure that the abrasive mixture meets the desired specifications, I:

- Use a calibrated scale to measure the proportions of each material

- Mix the materials for the correct amount of time

- Check the temperature of the mixture

- Add moisture to the mixture as needed

- Test the mixture to ensure it meets the desired specifications

8. What are the different types of abrasives?

The different types of abrasives include:

- Natural abrasives (e.g., sand, pumice, garnet)

- Synthetic abrasives (e.g., aluminum oxide, silicon carbide, boron nitride)

- Bonded abrasives (e.g., grinding wheels, sanding belts, coated abrasives)

9. What are the different grits of abrasives?

The different grits of abrasives are classified by the number of particles per square inch. The higher the grit number, the finer the abrasive. Common grit numbers include:

- 24

- 36

- 60

- 80

- 120

- 180

- 240

- 320

- 400

- 600

10. What are the different types of abrasive mixing machines?

The different types of abrasive mixing machines include:

- Paddle mixers

- Ribbon blenders

- Screw conveyors

- Air classifiers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Abrasive Mixer Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Abrasive Mixer Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Material Handling

Unloading and loading raw materials, such as abrasives, resins, and solvents, from trucks or storage areas.

2. Mixing and Blending

Assists in operating mixing equipment to combine raw materials according to specified formulas to create abrasive mixtures.

3. Equipment Maintenance

Cleaning and maintaining mixing equipment, including mixer blades, tanks, and conveyor belts.

4. Quality Assurance

Monitors the mixing process and takes samples for quality control testing to ensure that the abrasive mixtures meet specifications.

5. Safety and Compliance

Adheres to safety protocols, including wearing protective gear and following established procedures for handling hazardous materials.

Interview Tips

1. Research the Company and Position

Visit the company’s website and review the job description thoroughly. This will provide you with insights into the company’s culture, values, and the specific responsibilities of the Abrasive Mixer Helper role.

2. Practice Common Interview Questions

Anticipate standard interview questions such as “Tell me about yourself” and “Why are you interested in this position?” Prepare concise and well-structured answers that highlight your skills and experience.

3. Emphasize Safety Knowledge

Abrasive mixing can involve handling hazardous materials. Demonstrate your understanding of safety protocols, such as the use of personal protective equipment and emergency procedures.

4. Showcase Attention to Detail

Quality assurance is crucial in abrasive mixing. Highlight your ability to pay attention to details, follow instructions precisely, and ensure that mixtures meet specifications.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Inquire about the company’s growth plans, the team you would be working with, or the opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Abrasive Mixer Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Abrasive Mixer Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.