Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Blow Pit Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Blow Pit Helper so you can tailor your answers to impress potential employers.

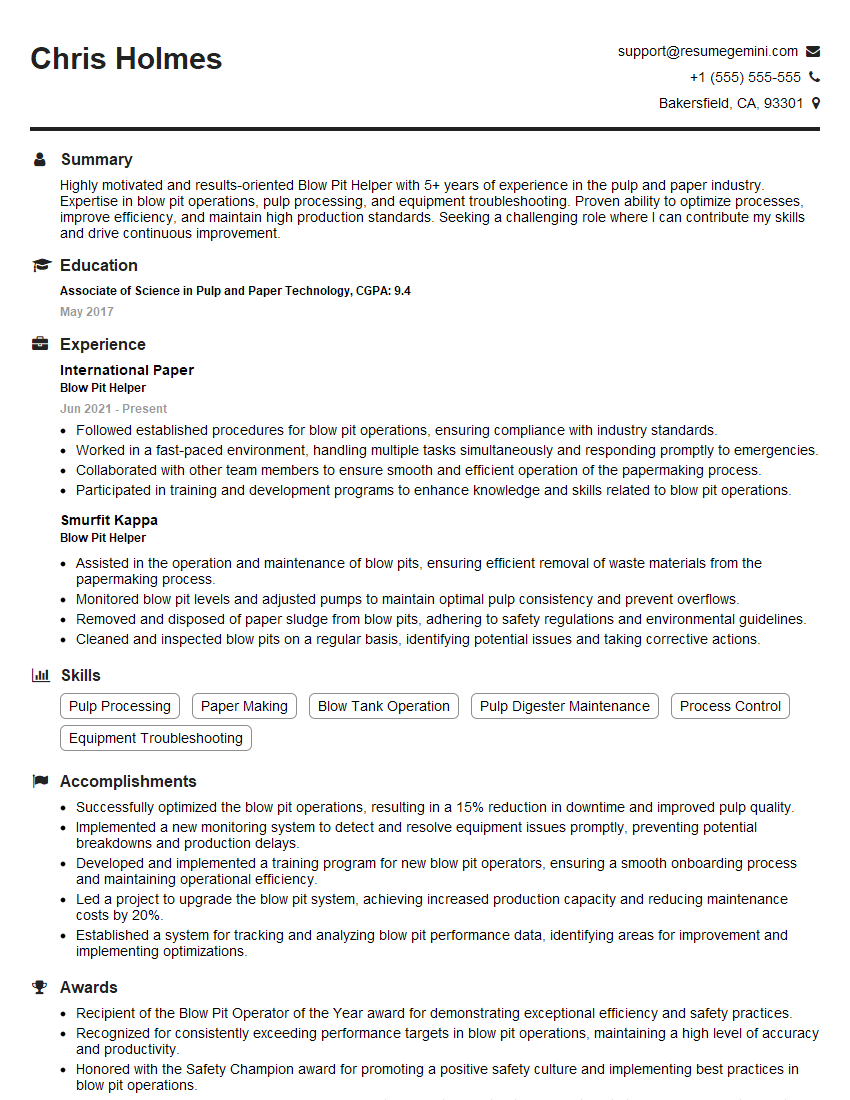

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blow Pit Helper

1. How would you prepare the blow pit for operation?

To prepare the blow pit for operation, I would first perform a thorough inspection to ensure that all components are in good working order.

- I would check the level of the pit and the agitator, making sure that they are both at the correct levels.

- I would then check the pumps and valves to ensure that they are functioning properly.

- Once I have completed the inspection, I would start the agitator and pumps to begin circulating the pulp.

2. What are the different types of pulp that can be handled in a blow pit?

There are three different types of pulp that can be handled in a blow pit:

Chemical pulp

- Chemical pulp is made by cooking wood chips in a chemical solution, which breaks down the lignin and cellulose fibers.

- Chemical pulp is used to make a variety of paper products, including printing and writing paper, tissue paper, and cardboard.

Mechanical pulp

- Mechanical pulp is made by grinding wood chips against a rotating stone.

- Mechanical pulp is used to make newsprint and other low-quality paper products.

Recycled pulp

- Recycled pulp is made from waste paper that has been collected and processed.

- Recycled pulp is used to make a variety of paper products, including printing and writing paper, tissue paper, and cardboard.

3. What are the potential hazards associated with working in a blow pit?

There are several potential hazards associated with working in a blow pit, including:

- Exposure to chemicals: The chemicals used in the pulping process can be harmful if inhaled or ingested.

- Exposure to noise: The blow pit can be a very noisy environment, which can lead to hearing loss.

- Exposure to heat: The blow pit can be a very hot environment, which can lead to heat stress.

- Slips and falls: The blow pit can be a slippery environment, which can lead to slips and falls.

- Caught-in hazards: The agitator and pumps in the blow pit can be caught-in hazards.

4. What are the proper procedures for handling pulp in a blow pit?

The proper procedures for handling pulp in a blow pit include:

- Wearing the proper personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and a respirator.

- Never entering the blow pit unless it has been properly locked out and tagged out.

- Using a scoop or other tool to handle pulp, never using your hands.

- Being aware of the location of all hazards in the blow pit, including the agitator, pumps, and valves.

- Following all written procedures and instructions for handling pulp in a blow pit.

5. What are the signs and symptoms of heat stress?

The signs and symptoms of heat stress include:

- Headache

- Nausea

- Vomiting

- Dizziness

- Lightheadedness

- Confusion

- Seizures

- Loss of consciousness

6. What are the first aid procedures for heat stress?

The first aid procedures for heat stress include:

- Moving the victim to a cool environment.

- Removing the victim’s clothing.

- Applying cool water to the victim’s skin.

- Giving the victim cool water to drink.

- Monitoring the victim’s vital signs.

- Calling for medical help if the victim’s condition does not improve.

7. What are the different types of valves used in a blow pit system?

The different types of valves used in a blow pit system include:

- Gate valves

- Globe valves

- Check valves

- Ball valves

- Butterfly valves

8. What are the functions of the different types of valves used in a blow pit system?

The functions of the different types of valves used in a blow pit system include:

Gate valves

- Gate valves are used to isolate a section of pipe or equipment.

- Gate valves are fully open or fully closed.

Globe valves

- Globe valves are used to regulate the flow of fluid.

- Globe valves have a disk that moves up and down to control the flow of fluid.

Check valves

- Check valves are used to prevent the backflow of fluid.

- Check valves have a flapper or ball that closes when the flow of fluid reverses.

Ball valves

- Ball valves are used to isolate a section of pipe or equipment.

- Ball valves have a ball that rotates to control the flow of fluid.

Butterfly valves

- Butterfly valves are used to regulate the flow of fluid.

- Butterfly valves have a disk that rotates to control the flow of fluid.

9. What are the maintenance procedures for the different types of valves used in a blow pit system?

The maintenance procedures for the different types of valves used in a blow pit system include:

- Inspecting the valves for leaks and damage.

- Lubricating the valves as per manufacturer’s instructions.

- Replacing the valves if they are damaged or leaking.

10. What are the troubleshooting procedures for the different types of valves used in a blow pit system?

The troubleshooting procedures for the different types of valves used in a blow pit system include:

- Identifying the problem with the valve.

- Determining the cause of the problem.

- Repairing the valve or replacing it if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blow Pit Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blow Pit Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blow Pit Helpers are crucial members of a paper mill’s production team, responsible for monitoring and assisting in the operation of the blow pit, which removes impurities from pulp.

1. Blow Pit Operation

Monitors and controls the operation of the blow pit, including adjusting water flow and chemical addition to ensure efficient removal of impurities.

- Observes pulp consistency and makes necessary adjustments to maintain optimum levels.

- Ensures proper functioning of blow pit equipment, such as pumps, valves, and screens.

2. Pulp Quality Monitoring

Conducts routine tests to monitor pulp quality, including fiber length, brightness, and consistency.

- Identifies potential issues with pulp quality and takes corrective actions.

- Maintains accurate records of pulp quality parameters.

3. Equipment Maintenance

Performs basic maintenance and cleaning of blow pit equipment, including screens, pumps, and valves.

- Lubricates and adjusts equipment to ensure smooth operation.

- Reports any equipment malfunctions or repairs needed to supervisors.

4. Safety and Environmental Compliance

Adheres to all safety and environmental regulations related to blow pit operations.

- Wears appropriate personal protective equipment (PPE) and follows established safety protocols.

- Ensures compliance with environmental regulations, such as wastewater discharge limits.

Interview Tips

Preparing for a Blow Pit Helper interview requires a combination of technical knowledge and a strong understanding of the industry.

1. Research the Company and Role

Thoroughly research the paper mill and the specific role before the interview. This will demonstrate your interest and preparedness.

- Read the job description carefully and identify key responsibilities.

- Visit the company’s website and social media pages to learn about their culture and values.

2. Highlight Relevant Skills and Experience

Emphasize your experience in pulp and paper manufacturing, particularly in blow pit operations. Quantify your accomplishments and provide specific examples.

- Describe your responsibilities and contributions in previous blow pit helper roles.

- Share examples of how you improved pulp quality or reduced downtime through effective blow pit management.

3. Demonstrate Problem-Solving Abilities

Blow Pit Helpers often encounter unexpected situations. During the interview, anticipate potential problems and discuss your approach to solving them.

- Provide examples of how you have solved problems related to blow pit equipment or pulp quality.

- Explain your decision-making process and how you prioritize tasks in a fast-paced environment.

4. Showcase Safety and Environmental Awareness

Safety and environmental compliance are paramount in blow pit operations. Emphasize your understanding of safety protocols and environmental regulations.

- Describe your experience in following established safety procedures and using appropriate PPE.

- Discuss your knowledge of environmental regulations related to wastewater discharge and air emissions.

Next Step:

Now that you’re armed with the knowledge of Blow Pit Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blow Pit Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini