Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Brewer Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

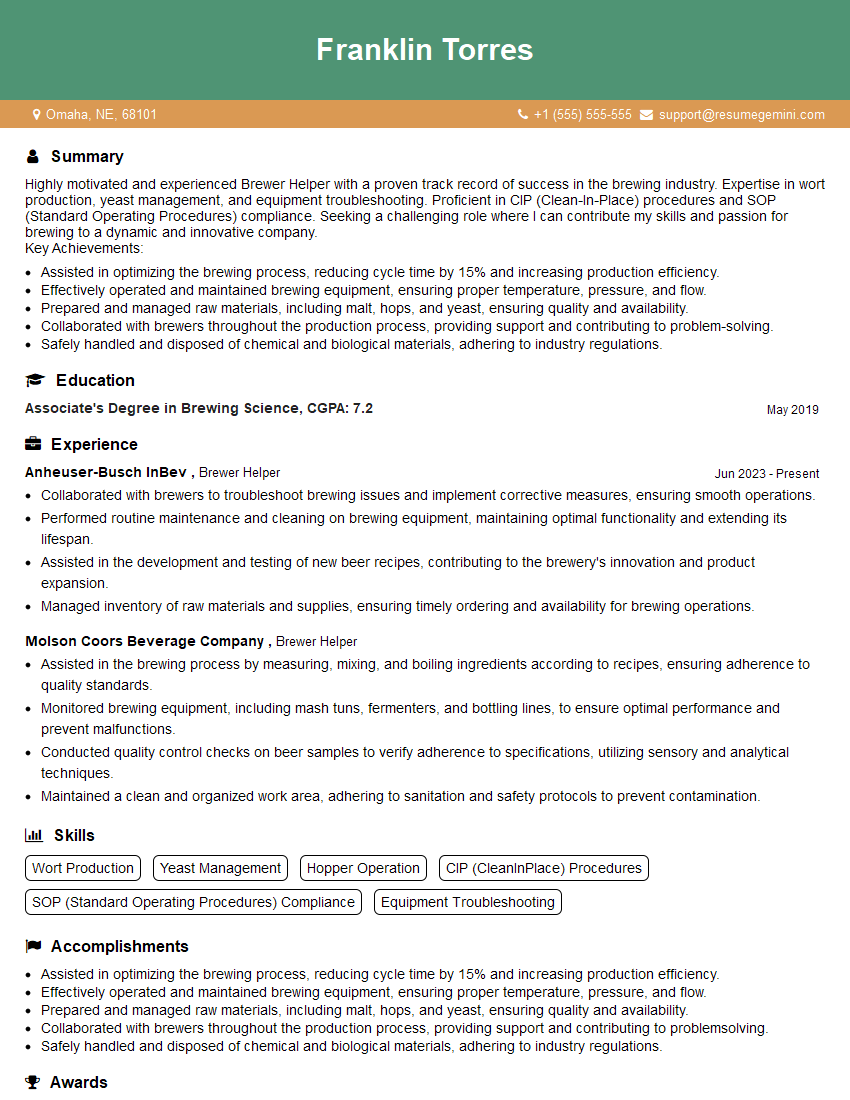

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brewer Helper

1. Explain the process of mashing in brewing?

Mashing is the process of combining crushed malt with hot water to create a sugary liquid called wort. The temperature of the water and the length of time the malt is steeped in the water determine the type of wort that is produced.

- The first step in mashing is to mill the malt. The malt is crushed into a coarse powder, which exposes the starch granules to the water.

- The milled malt is then mixed with hot water in a mash tun. The temperature of the water is typically between 145 and 155 degrees Fahrenheit.

- The mash is then allowed to rest for a period of time, typically between 60 and 90 minutes. During this time, the enzymes in the malt convert the starches into sugars.

- After the mash has rested, it is lautered. This process separates the wort from the spent grain. The wort is then boiled and fermented to produce beer.

2. What are the different types of hops used in brewing?

Aroma hops

- Aroma hops are added to the wort late in the boiling process. They contribute flavor and aroma to the beer, but they do not add bitterness.

- Common aroma hops include Cascade, Citra, and Mosaic.

Bittering hops

- Bittering hops are added to the wort early in the boiling process. They contribute bitterness to the beer, but they do not add much flavor or aroma.

- Common bittering hops include Magnum, Warrior, and Chinook.

Dual-purpose hops

- Dual-purpose hops can be used for both bittering and aroma. They contribute both bitterness and flavor to the beer.

- Common dual-purpose hops include Simcoe, Amarillo, and Centennial.

3. What is the role of yeast in brewing?

Yeast is a fungus that converts sugars into alcohol and carbon dioxide. In brewing, yeast is used to ferment the wort, which is the sugary liquid produced by mashing. The fermentation process produces the alcohol and carbon dioxide that give beer its characteristic flavor and effervescence.

- There are many different strains of yeast that can be used for brewing. Each strain of yeast produces a slightly different flavor profile in the beer.

- The type of yeast that is used for a particular beer will depend on the desired flavor profile.

4. What are the different types of beer?

There are many different types of beer, each with its own unique flavor and aroma. Some of the most common types of beer include:

- Ales: Ales are fermented at warm temperatures, typically between 60 and 75 degrees Fahrenheit. They are typically light in color and have a fruity flavor.

- Lagers: Lagers are fermented at cold temperatures, typically between 40 and 55 degrees Fahrenheit. They are typically light in color and have a crisp, refreshing flavor.

- Stouts: Stouts are dark in color and have a rich, malty flavor. They are typically made with roasted barley, which gives them their dark color and flavor.

- Porters: Porters are dark in color and have a slightly sweet flavor. They are typically made with roasted barley and chocolate malt, which gives them their dark color and flavor.

5. What are the different stages of the brewing process?

- Mashing: The process of combining crushed malt with hot water to create a sugary liquid called wort.

- Lautering: The process of separating the wort from the spent grain.

- Boiling: The process of boiling the wort to sterilize it and extract the flavors from the hops.

- Fermentation: The process of converting the wort into beer by adding yeast.

- Conditioning: The process of allowing the beer to mature and develop its flavor.

- Packaging: The process of bottling or kegging the beer.

6. What are the different types of brewing equipment?

- Mash tun: The vessel in which the mash is created.

- Lauter tun: The vessel in which the wort is separated from the spent grain.

- Brew kettle: The vessel in which the wort is boiled.

- Fermenter: The vessel in which the wort is fermented.

- Conditioning tank: The vessel in which the beer is allowed to mature and develop its flavor.

- Bottling line: The equipment used to bottle the beer.

- Kegging line: The equipment used to keg the beer.

7. What are the safety hazards associated with brewing?

- Burns: The wort and boiling water can cause burns.

- Cuts: The sharp edges of the brewing equipment can cause cuts.

- Slips and falls: The brewery floor can be wet and slippery, which can lead to slips and falls.

- Chemical exposure: The chemicals used in brewing, such as hops and yeast, can cause skin irritation and respiratory problems.

8. What are the quality control procedures used in brewing?

- Raw material inspection: The raw materials used in brewing, such as malt, hops, and yeast, are inspected to ensure that they meet quality standards.

- Process monitoring: The brewing process is monitored to ensure that it is operating within the desired parameters.

- Finished product testing: The finished beer is tested to ensure that it meets quality standards.

9. What are the different career opportunities in the brewing industry?

- Brewer: The brewer is responsible for overseeing the brewing process.

- Cellarman: The cellarman is responsible for the care and maintenance of the beer during fermentation and conditioning.

- Packaging operator: The packaging operator is responsible for bottling or kegging the beer.

- Quality control technician: The quality control technician is responsible for ensuring that the beer meets quality standards.

- Sales representative: The sales representative is responsible for selling the beer to distributors and retailers.

10. What is your favorite style of beer?

My favorite style of beer is a hoppy IPA. I love the bitter, citrusy flavor of hops. I also enjoy the malty sweetness that balances out the bitterness.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brewer Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brewer Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Brewer Helper, also known as a Brewery Worker or Cellarman Assistant, plays a crucial role in the brewing process by assisting experienced brewers in various tasks. Their primary objective is to maintain a clean and efficient work environment while ensuring the quality of the produced beer.

1. Assisting with Brewing Operations

Brewer Helpers actively participate in the brewing process by performing tasks such as:

- Cleaning and sanitizing brewing equipment, including fermenters, mash tuns, and kegs.

- Transferring wort (unfermented beer) between vessels during the brewing process.

- Monitoring temperatures, pH levels, and other parameters during fermentation and storage.

2. Maintaining the Brewery

Brewer Helpers maintain a clean and organized work environment by:

- Cleaning and sanitizing work areas, including floors, walls, and equipment.

- Inspecting and maintaining equipment and machinery to ensure proper operation.

- Assisting with repairs and maintenance tasks as needed.

3. Packaging and Distribution

Brewer Helpers contribute to the packaging and distribution process by:

- Filling and labeling bottles, cans, or kegs with finished beer.

- Loading and unloading beer onto trucks for distribution.

- Maintaining inventory levels of packaging materials and finished products.

4. Quality Control

Brewer Helpers contribute to quality control by:

- Sampling and testing beer at various stages of production.

- Monitoring and reporting on quality parameters to ensure compliance with standards.

- Assisting with troubleshooting and resolving quality issues.

Interview Tips

To ace an interview for a Brewer Helper position, candidates should consider the following preparation tips:

1. Research the Brewery and Industry

Demonstrate your interest in the specific brewery and the brewing industry by researching their history, products, and current events. This shows that you are enthusiastic about the opportunity and invested in learning more.

- Visit the brewery’s website and social media pages.

- Read industry news and publications to stay updated on trends and best practices.

- Consider your favorite beers and why you enjoy them, which can provide insights into your knowledge and appreciation of the craft.

2. Highlight Relevant Skills and Experience

Emphasize your previous experience in similar roles or industries, even if not directly related to brewing. Focus on transferable skills, such as:

- Cleaning and sanitation

- Attention to detail

- Physical strength and stamina

- Teamwork and communication

3. Prepare for Common Interview Questions

Anticipate and prepare for common interview questions, such as:

- Tell me about yourself and why you’re interested in this role.

- What relevant skills and experience do you have that make you suitable for this position?

- How do you handle working in a fast-paced and physically demanding environment?

- Describe your understanding of the brewing process and quality control procedures.

- What are your career goals and aspirations?

4. Dress Professionally and Be Enthusiastic

First impressions matter, so dress appropriately for the interview. Be punctual, show enthusiasm, and maintain eye contact. Remember that the brewery wants to hire individuals who are passionate about beer and eager to contribute to the team.

- Wear clean and pressed clothing that is suitable for a brewery environment.

- Arrive on time for your interview and be prepared to answer questions about your interest in the job.

- Practice your answers to common interview questions and be prepared to ask your own questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brewer Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.