Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Clarifier Operator Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

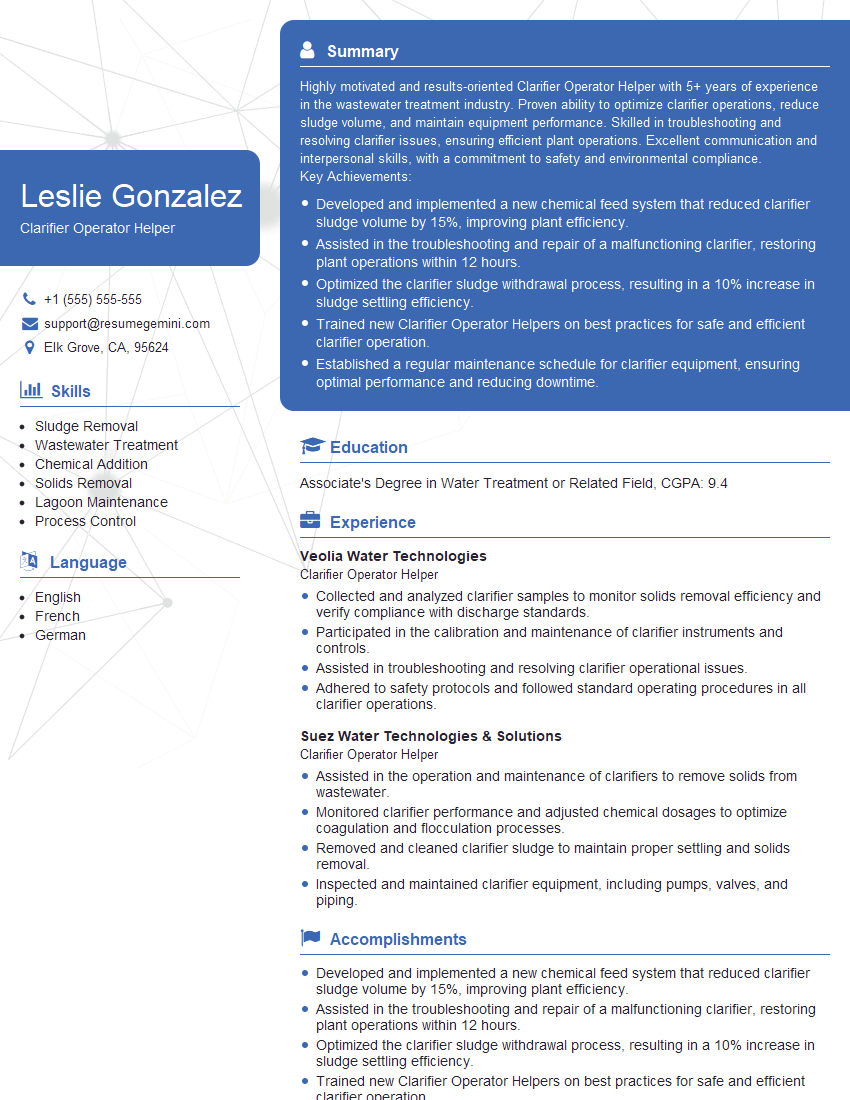

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clarifier Operator Helper

1. What are the key responsibilities of a Clarifier Operator Helper?

As a Clarifier Operator Helper, my responsibilities would include:

- Monitoring and adjusting the operation of clarifiers to ensure efficient removal of solids from wastewater

- Collecting and analyzing samples to monitor the performance of the clarifiers and make necessary adjustments

- Maintaining and cleaning clarifiers and associated equipment to ensure proper operation

- Following established safety protocols and procedures

- Working as part of a team to ensure the smooth operation of the wastewater treatment plant

2. Describe the process of sludge removal from a clarifier.

Clarifier Operation

- Raw wastewater enters the clarifier and flows through a series of baffles to reduce its velocity

- The reduced velocity allows solids to settle to the bottom of the clarifier

- The settled solids form a sludge layer at the bottom of the clarifier

Sludge Removal

- Sludge is removed from the clarifier using sludge pumps or gravity

- The sludge is pumped to a sludge thickener or dewatering unit to reduce its volume

- The thickened or dewatered sludge is then disposed of or further processed

3. How do you maintain the proper pH levels in a clarifier?

- Monitor the pH of the influent and effluent wastewater regularly using a pH meter

- Add chemicals such as lime or soda ash to raise the pH or sulfuric acid to lower the pH

- Check the pH of the sludge to ensure it is within the desired range

- Adjust the chemical dosage rates as necessary to maintain the target pH levels

4. What are the common operational problems encountered in clarifiers and how do you troubleshoot them?

- Short-circuiting: Water flowing through the clarifier without proper settling. This can be caused by excessive flow rates, uneven distribution of influent, or damaged baffles.

- Overloading: Excessive solids loading can cause the clarifier to become overloaded and result in poor solids removal. This can be addressed by reducing the solids loading or increasing the clarifier capacity.

- Sludge bulking: Buoyant sludge that fails to settle properly. This can be caused by biological factors such as filamentous bacteria or chemical factors such as high organic loading. It can be addressed by optimizing the biological process or using chemical additives to improve sludge settling.

- Floating solids: Solids that float on the surface of the clarifier. This can be caused by fats, oils, or grease in the influent. It can be addressed by using skimmers or chemical additives to remove the floating solids.

5. How do you ensure the safety of yourself and others when working with clarifiers?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a hard hat

- Be aware of the potential hazards associated with clarifiers, such as slippery surfaces, moving equipment, and electrical hazards

- Follow established safety procedures and protocols

- Never enter a clarifier without proper authorization and supervision

- Be aware of the location of emergency equipment and evacuation routes

6. What are the different types of clarifiers and their applications?

- Primary clarifiers: Used to remove settleable solids from raw wastewater

- Secondary clarifiers: Used to remove biological solids from activated sludge or trickling filter effluents

- Tertiary clarifiers: Used to further polish wastewater for reuse or discharge

- Lamella clarifiers: Use inclined plates to increase the settling area and improve solids removal

- Package clarifiers: Prefabricated clarifiers that are typically smaller and more compact

7. How do you calculate the overflow rate and detention time in a clarifier?

Overflow Rate

- Overflow rate = Flow rate / Surface area of clarifier

- Units: gallons per minute per square foot (gpm/sq ft)

Detention Time

- Detention time = Volume of clarifier / Flow rate

- Units: hours

8. What are the key performance indicators (KPIs) for a clarifier?

- Solids removal efficiency

- Overflow rate

- Detention time

- Sludge blanket height

- Chemical consumption

- Energy consumption

9. Describe your experience with troubleshooting and repairing clarifiers.

In my previous role, I was responsible for maintaining and repairing clarifiers. Some of the common issues I encountered and resolved include:

- Overloading: Increased the clarifier capacity by adding additional settling area

- Short-circuiting: Installed baffles to improve flow distribution and reduce short-circuiting

- Sludge bulking: Optimized the biological process by adjusting the aeration and mixing conditions

- Floating solids: Installed skimmers to remove floating solids from the clarifier surface

- Mechanical problems: Repaired or replaced faulty pumps, valves, and other mechanical components

10. How do you stay up-to-date with the latest advancements in clarifier technology?

- Attend industry conferences and workshops

- Read technical journals and articles

- Participate in online forums and discussion groups

- Consult with clarifier manufacturers and experts

- Take continuing education courses

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clarifier Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clarifier Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clarifier Operator Helper is responsible for assisting the Clarifier Operator in the operation and maintenance of a water treatment plant’s clarification process. Key responsibilities include:

1. Assist in monitoring and controlling the clarification process

This involves:

- Monitoring the influent and effluent water quality parameters

- Adjusting chemical dosages and equipment settings to maintain desired water quality levels

2. Assist in operating and maintaining clarification equipment

This involves:

- Cleaning and maintaining clarifiers, filters, and other equipment

- Troubleshooting and repairing equipment malfunctions

3. Assist in performing laboratory tests

This involves:

- Collecting and analyzing water samples to ensure compliance with regulatory standards

- Conducting jar tests to optimize chemical dosages

4. Assist in maintaining a safe and clean work environment

This involves:

- Following safety protocols and procedures

- Keeping the work area clean and organized

Interview Tips

To ace the interview for a Clarifier Operator Helper position, candidates should:

1. Research the company and the position

This will help you understand the company’s culture, values, and the specific requirements of the role.

2. Practice answering common interview questions

This will help you feel more confident and prepared during the interview. Common interview questions for this position include:

- “Tell me about your experience in water treatment.”

- “What are your strengths and weaknesses as a Clarifier Operator Helper?”

- “How do you handle working in a team environment?”

3. Showcase your skills and experience

During the interview, be sure to highlight your relevant skills and experience. This may include your experience in operating and maintaining water treatment equipment, your knowledge of water treatment processes, and your commitment to safety.

4. Be prepared to discuss your career goals

The interviewer may ask you about your career goals. Be prepared to discuss your short-term and long-term goals, and how this position aligns with your career aspirations.

5. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Clarifier Operator Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.