Are you gearing up for an interview for a Coppersmith Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coppersmith Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

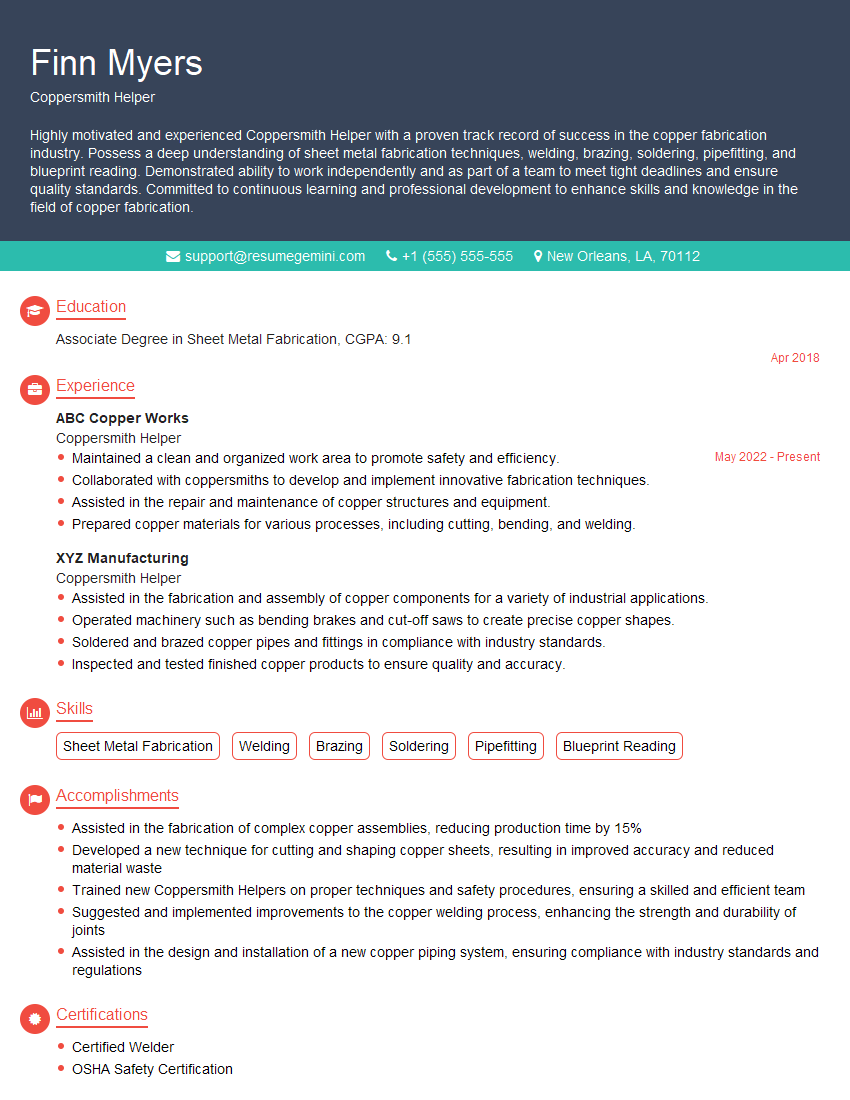

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coppersmith Helper

1. Describe the process of soldering copper pipes.

- Clean the pipes and fittings with a wire brush or sandpaper.

- Apply flux to the pipes and fittings.

- Heat the pipes and fittings with a propane torch.

- Touch the solder to the joint and allow it to flow into the gap.

- Cool the joint with a wet rag.

2. What are the different types of copper fittings and what are their uses?

Compression fittings

- Used to connect copper pipes of the same size.

- Consist of a nut, ferrule, and body.

- Easy to install and remove.

Flared fittings

- Used to connect copper pipes of different sizes.

- Consist of a nut, ferrule, and flare.

- Require a flaring tool to install.

Solder fittings

- Used to create permanent connections between copper pipes.

- Consist of a cup and a solder ring.

- Require a propane torch to install.

3. What are the safety precautions that must be taken when working with copper piping?

- Wear safety glasses and gloves.

- Use a well-ventilated area.

- Keep a fire extinguisher nearby.

- Do not smoke or use open flames near copper piping.

4. What are the different types of copper tubing and what are their uses?

Type L

- Used for water supply lines.

- Has a thinner wall thickness than other types of copper tubing.

Type M

- Used for gas lines and refrigeration lines.

- Has a thicker wall thickness than Type L.

Type K

- Used for underground applications.

- Has a thicker wall thickness than Type M.

5. What are the tools and equipment that are required for copper piping work?

- Pipe cutter

- Deburring tool

- Soldering torch

- Solder

- Flux

- Compression fittings

- Flared fittings

- Solder fittings

6. What are the steps involved in bending copper tubing?

- Measure and mark the bend radius.

- Bend the tube using a tube bender.

- Anneal the bend using a propane torch.

- Cool the bend with a wet rag.

7. What are the causes of leaks in copper piping systems?

- Poorly soldered joints

- Damaged pipes

- Loose fittings

- Corrosion

8. What are the signs of a clogged copper pipe?

- Reduced water flow

- Gurgling sounds

- Bad odors

9. What are the methods that can be used to clean a clogged copper pipe?

- Chemical cleaners

- Mechanical snakes

- Hydro jetting

10. What are the advantages of using copper piping?

- Durable

- Corrosion-resistant

- Antimicrobial

- Recyclable

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coppersmith Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coppersmith Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Assist in Copper Fabrication and Installation

- Cut and shape copper sheets, tubes, and other materials using hand and power tools.

- Join copper components using soldering, brazing, or welding techniques to form pipes, ducts, and other structures.

- Install fabricated copper components in accordance with blueprints and specifications.

- Help assemble and install copper roofing systems, including gutters, downspouts, and flashing.

2. Maintain Equipment and Tools

- Keep work area clean and organized, following safety protocols.

- Inspect and maintain tools and equipment, ensuring they are in good working order.

- Report any equipment malfunctions or maintenance issues promptly.

3. Assist in Maintenance and Repair

- Help diagnose and repair copper-related components, such as pipes, fittings, and connections.

- Perform routine maintenance tasks, such as cleaning, tightening, and lubricating components.

- Assist with emergency repairs and breakdowns.

4. Support Other Coppersmiths

- Assist other coppersmiths in performing various tasks, such as holding materials, operating equipment, and cleaning up work areas.

- Follow instructions and guidance provided by experienced coppersmiths.

- Learn from skilled coppersmiths to enhance own knowledge and skills.

Interview Tips

1. Research the Company and Industry

- Visit the company’s website to learn about its history, products/services, and values.

- Research the copper fabrication industry to understand the latest trends and technologies.

- This knowledge will help you demonstrate your interest in the field and the company.

2. Practice Your Skills

- Review common copper fabrication techniques and prepare to discuss your experience with these.

- Practice answering questions about your familiarity with tools and equipment used in copper work.

- Practicing will boost your confidence and enable you to clearly articulate your abilities.

3. Highlight Your Safety Awareness

- Emphasize your understanding of safety protocols in a metalworking environment.

- Describe your experience in handling hazardous materials and using safety gear.

- Hiring managers prioritize safety, and your awareness of these aspects will make a positive impression.

4. Show Your Willingness to Learn

- Express your eagerness to learn new techniques and technologies in copper fabrication.

- Mention your willingness to take on additional responsibilities and challenges.

- Your enthusiasm for growth and development will be highly valued by potential employers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coppersmith Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!