Feeling lost in a sea of interview questions? Landed that dream interview for Cylinder Die Machine Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cylinder Die Machine Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

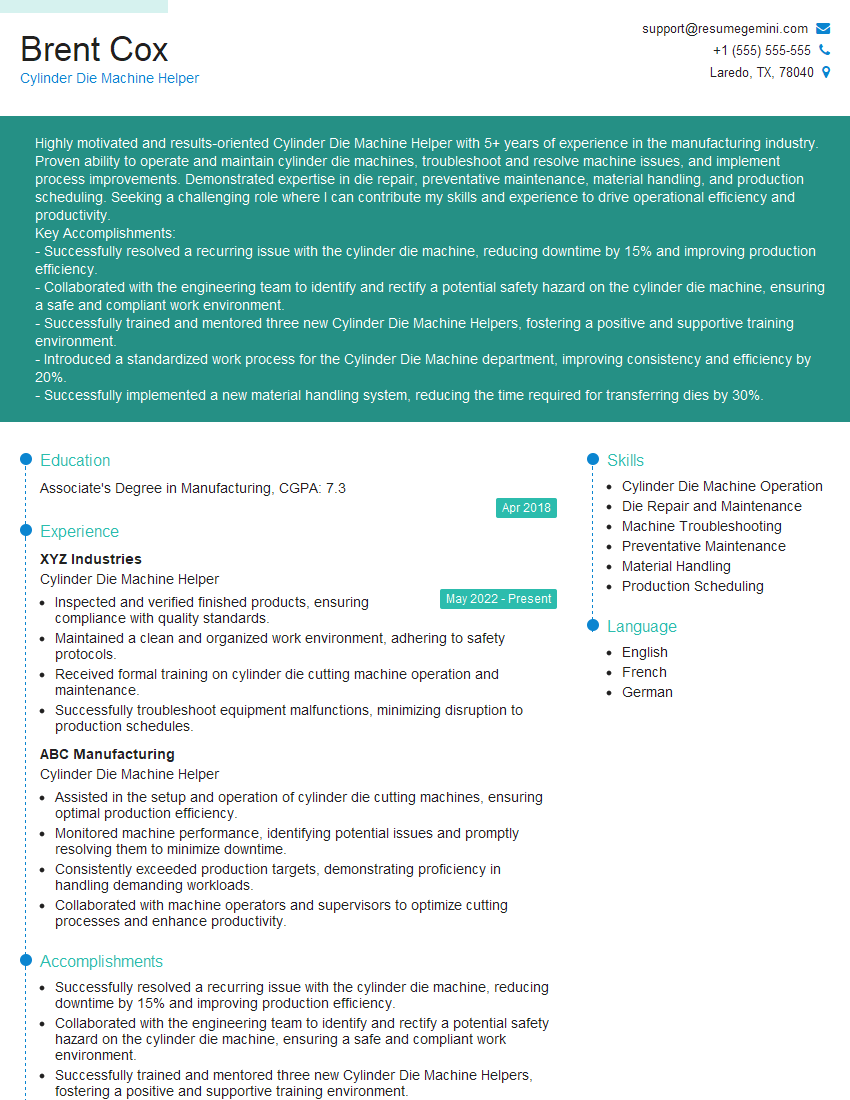

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cylinder Die Machine Helper

1. Describe the process of setting up a cylinder die machine.

The process of setting up a cylinder die machine typically involves the following steps:

- Mount the die onto the machine.

- Lubricate the machine and adjust the speed.

- Thread the material through the machine.

- Calibrate the machine to the desired cut size.

- Start the machine and monitor its operation.

2. What are the different types of materials that can be cut on a cylinder die machine?

Cylinder die machines can cut a variety of materials, including:

Paper products

- Cardboard

- Paperboard

- Corrugated board

Plastic products

- Polyethylene

- Polypropylene

- Polyvinyl chloride

Metal products

- Aluminum

- Steel

- Copper

3. What are the safety precautions that should be taken when operating a cylinder die machine?

The following safety precautions should be taken when operating a cylinder die machine:

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Keep hands and clothing away from moving parts.

- Do not operate the machine if it is not properly lubricated.

- Do not attempt to clear jams without first stopping the machine.

- Be aware of the machine’s operating temperature and take precautions to avoid burns.

4. What are the common problems that can occur when operating a cylinder die machine?

Some common problems that can occur when operating a cylinder die machine include:

- Jamming

- Tearing

- Misalignment

- Die wear

- Machine overheating

5. How do you troubleshoot a cylinder die machine?

To troubleshoot a cylinder die machine, the following steps can be taken:

- Identify the problem.

- Check the machine for any obvious problems, such as loose parts or damaged components.

- Refer to the machine’s manual for troubleshooting tips.

- Contact the machine manufacturer for assistance.

6. What are the maintenance procedures that should be performed on a cylinder die machine?

The following maintenance procedures should be performed on a cylinder die machine:

- Regularly lubricate the machine.

- Inspect the machine for any loose parts or damaged components.

- Sharpen or replace the die as needed.

- Clean the machine regularly to remove any dust or debris.

7. What are the quality control procedures that should be followed when operating a cylinder die machine?

The following quality control procedures should be followed when operating a cylinder die machine:

- Inspect the material before cutting to ensure that it is free of defects.

- Monitor the machine’s operation to ensure that the cuts are being made correctly.

- Inspect the finished product to ensure that it meets the desired specifications.

8. What are the different types of dies that can be used on a cylinder die machine?

The following types of dies can be used on a cylinder die machine:

- Round dies

- Square dies

- Rectangular dies

- Custom dies

9. How do you calculate the cutting force required for a cylinder die machine?

The cutting force required for a cylinder die machine can be calculated using the following formula:

F = S x t x Y

where:

- F is the cutting force (in pounds)

- S is the shear strength of the material (in pounds per square inch)

- t is the thickness of the material (in inches)

- Y is the yield factor (a constant that depends on the material and the die geometry)

10. How do you adjust the speed of a cylinder die machine?

The speed of a cylinder die machine can be adjusted by changing the following variables:

- The speed of the motor

- The gear ratio of the machine

- The tension of the material

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cylinder Die Machine Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cylinder Die Machine Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cylinder Die Machine Helper, also known as a Press Operator Helper, plays a pivotal role in assisting Cylinder Die Machine Operators with various aspects of job execution and machine maintenance.

1. Material Handling

Ensures a steady supply of materials required for machine operation by coordinating with the production team.

- Loads and unloads raw materials onto the machine using forklifts or manually.

- Operates cranes or hoists to move heavy materials.

2. Machine Preparation and Setup

Assists in setting up the machine for specific production runs.

- Follows setup instructions and verifies machine parameters.

- Attaches and adjusts dies or tooling as directed.

3. Quality Control and Inspection

Monitors product quality during production and conducts basic inspections.

- Identifies and removes defective products from the production line.

- Records any issues or deviations from quality standards.

4. Machine Maintenance

Performs routine maintenance tasks to ensure optimal machine performance.

- Cleans and lubricates machine components.

- Replaces worn or damaged parts as needed.

5. Safety Compliance

Adheres to all safety protocols and procedures in the work area.

- Wears appropriate safety gear and follows safety guidelines.

- Reports any safety concerns or hazards immediately.

Interview Preparation Tips for Cylinder Die Machine Helper

To ace the interview and demonstrate your qualifications as a Cylinder Die Machine Helper, consider the following tips:

1. Highlighting Relevant Experience

Emphasize your previous experience in similar roles, particularly in operating or assisting in cylinder die machine operations.

- Quantify your accomplishments and provide specific examples of your contributions.

- Describe your familiarity with different types of cylinder die machines and materials.

2. Teamwork and Safety

Stress your ability to work effectively as part of a team and your commitment to workplace safety.

- Share instances where you have collaborated with others to achieve common goals.

- Highlight your understanding of safety protocols and your experience in maintaining a safe work environment.

3. Mechanical Aptitude and Attention to Detail

Demonstrate your strong mechanical aptitude and attention to detail.

- Describe your experience in performing basic machine maintenance tasks.

- Provide examples of how your sharp observation skills help you identify and address potential issues early on.

4. Commitment to Quality

Convince the interviewer of your dedication to producing high-quality work.

- Emphasize your commitment to following instructions and adhering to quality standards.

- Share any experience in conducting quality inspections or troubleshooting quality issues.

5. Preparation and Follow-Up

Come prepared to the interview by researching the company and the role.

- Prepare thoughtful questions to ask the interviewer about the company’s operations and the specific responsibilities of the position.

- After the interview, follow up with a thank-you note reiterating your interest in the role.

Next Step:

Now that you’re armed with the knowledge of Cylinder Die Machine Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cylinder Die Machine Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini