Feeling lost in a sea of interview questions? Landed that dream interview for Drawbench Operator Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Drawbench Operator Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

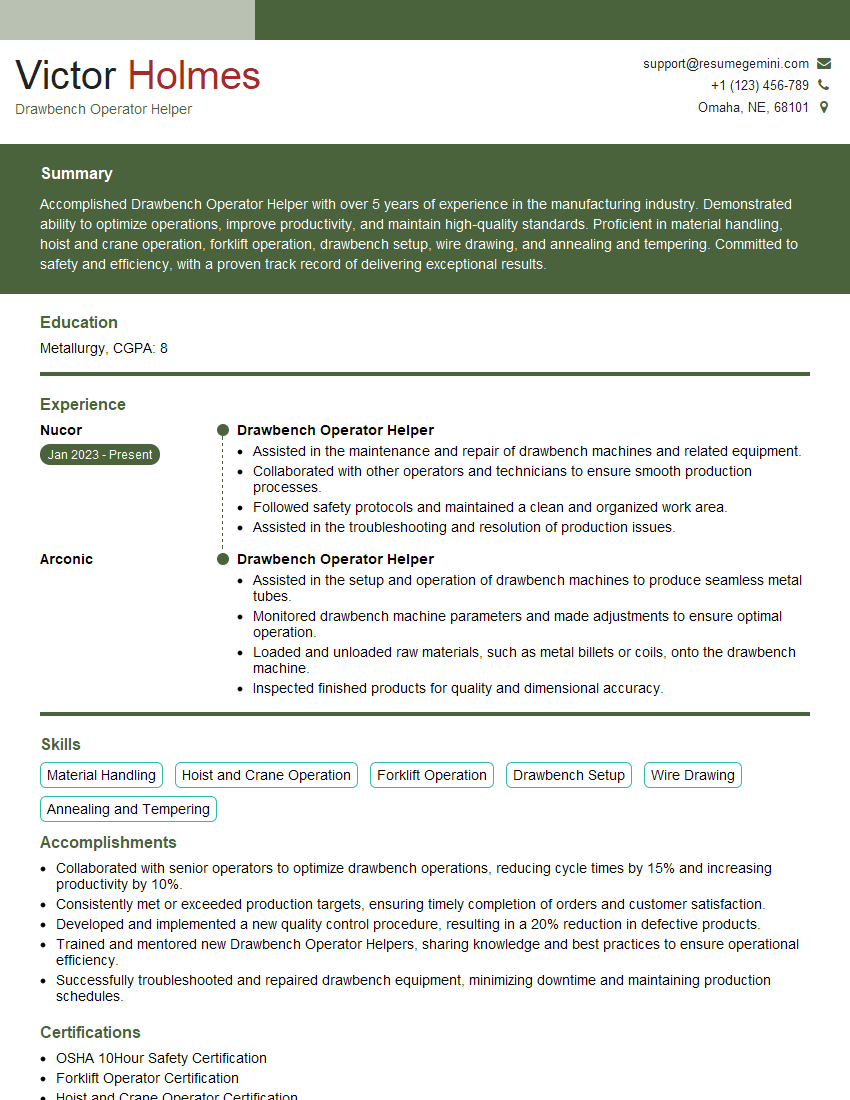

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drawbench Operator Helper

1. How do you calculate the theoretical weight of a product?

To calculate the theoretical weight of a product, I would use the formula:

Theoretical weight (lbs.) = (Length (in.) x Width (in.) x Thickness (in.)) x Density (lb./in.)

2. What are the different types of dies used in drawbenching?

The different types of dies used in drawbenching include:

- Round dies

- Square dies

- Rectangular dies

- Hexagonal dies

- Special-shaped dies

3. Describe the importance of proper lubrication in drawbenching.

Proper lubrication in drawbenching is crucial for several reasons:

- Reduces friction between the material and the die, allowing for easier pulling.

- Prevents the material from sticking to the die, which can cause surface defects.

- Cools the material and die, which can prevent overheating and premature wear.

- Improves the surface finish of the drawn product.

4. What are the common material defects that can occur during drawbenching?

Common material defects that can occur during drawbenching include:

- Surface scratches

- Wrinkles

- Cracks

- Dimensional variations

- Internal voids

5. How do you troubleshoot a drawbench machine that is not pulling material smoothly?

Troubleshooting a drawbench machine that is not pulling material smoothly can involve several steps:

- Checking the condition of the dies and replacing any that are worn or damaged.

- Ensuring that the material is properly lubricated.

- Inspecting the draw chain for any signs of damage or excessive wear.

- Checking the tension in the draw chain and adjusting it if necessary.

- Checking the alignment of the machine and ensuring that all components are working properly.

6. What are the safety precautions that should be followed when operating a drawbench machine?

The safety precautions that should be followed when operating a drawbench machine include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Keeping hands and other body parts away from moving machine components.

- Never working on a machine that is running.

- Ensuring that the machine is in good working order before operating it.

- Following all manufacturer’s instructions and safety guidelines.

7. How do you maintain a drawbench machine to ensure optimal performance?

To maintain a drawbench machine for optimal performance, regular maintenance is essential:

- Cleaning the machine daily and removing any dirt or debris.

- Lubricating all moving parts regularly.

- Inspecting the dies, draw chain, and other components for wear and damage.

- Performing regular adjustments to ensure the machine is operating properly.

- Following all manufacturer’s maintenance recommendations.

8. What are the different types of drawbench products?

Drawbench products can vary in shape, size, and material:

- Round bars

- Square bars

- Rectangular bars

- Hexagonal bars

- Special-shaped profiles

- Tubes

- Pipes

9. What are the applications of drawbenching in various industries?

Drawbenching finds applications across various industries:

- Automotive: Producing seamless tubes for fuel lines, brake lines, and other components.

- Construction: Manufacturing structural members, such as beams and columns.

- Aerospace: Creating lightweight and high-strength components for aircraft and spacecraft.

- Medical: Producing medical devices like catheters, stents, and implants.

- Energy: Manufacturing seamless pipes for oil and gas transportation.

10. How do you determine the appropriate drawing speed for a given material and product size?

Determining the appropriate drawing speed involves considering several factors:

- Material properties: Softer materials require slower speeds to prevent tearing, while harder materials can withstand higher speeds.

- Product size: Larger products require slower speeds to maintain dimensional accuracy.

- Die design: Dies with smaller radii require slower speeds to avoid excessive bending.

- Lubrication: Proper lubrication reduces friction, allowing for higher drawing speeds.

- Machine capabilities: The drawbench machine’s capacity and speed range should be considered.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drawbench Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drawbench Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drawbench Operator Helper plays a pivotal role in the operation of drawbenches, assisting the Drawbench Operator in various tasks to ensure smooth and efficient production. Their key job responsibilities encompass the following:

1. Assisting with Drawbench Operation

Assist the Drawbench Operator in operating the drawbench machine, including setting up and adjusting the machine, feeding the material into the drawbench, and guiding the material through the draw die.

2. Monitoring Production

Monitor the drawbench process to ensure that the material is being drawn correctly and to identify any potential problems or deviations from the desired specifications.

3. Maintaining Equipment

Assist with the maintenance and cleaning of the drawbench machine, including lubrication, minor repairs, and ensuring that the equipment is in good working condition.

4. Preparing Materials

Prepare materials for the drawbench process, such as cutting the material to the correct length, straightening the material, and applying lubricants to reduce friction during the drawing process.

5. Ensuring Safety

Adhere to all safety regulations and guidelines, wear appropriate safety gear, and maintain a clean and organized work area to minimize the risk of accidents or injuries.

Interview Tips

To ace an interview for a Drawbench Operator Helper position, it is essential to prepare thoroughly and present yourself as a knowledgeable and motivated candidate. Here are some tips and hacks to help you succeed in the interview:

1. Research the Company and the Position

Research the company and the specific position you are applying for to gain a comprehensive understanding of their business, industry, and job requirements. This knowledge will enable you to tailor your answers to the interviewer’s questions, demonstrating your enthusiasm and interest in the role.

2. Highlight Relevant Skills and Experience

Emphasize the skills and experience that are most relevant to the Drawbench Operator Helper position. Focus on your ability to assist with drawbench operation, monitor production, maintain equipment, and prepare materials. Provide specific examples of your work history that demonstrate these skills.

3. Showcase Safety Awareness

Safety is paramount in any industrial setting. During the interview, highlight your commitment to safety by emphasizing your knowledge of safety regulations and your experience in maintaining a safe work environment. Describe specific examples of how you have prioritized safety in your previous roles.

4. Practice Common Interview Questions

Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”. Prepare concise and well-rehearsed responses that showcase your qualifications and motivations for the job.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions about the company’s culture, the drawbench operation process, or the training and development opportunities available. This shows that you are genuinely interested in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drawbench Operator Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.