Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dry Kiln Operator Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dry Kiln Operator Helper so you can tailor your answers to impress potential employers.

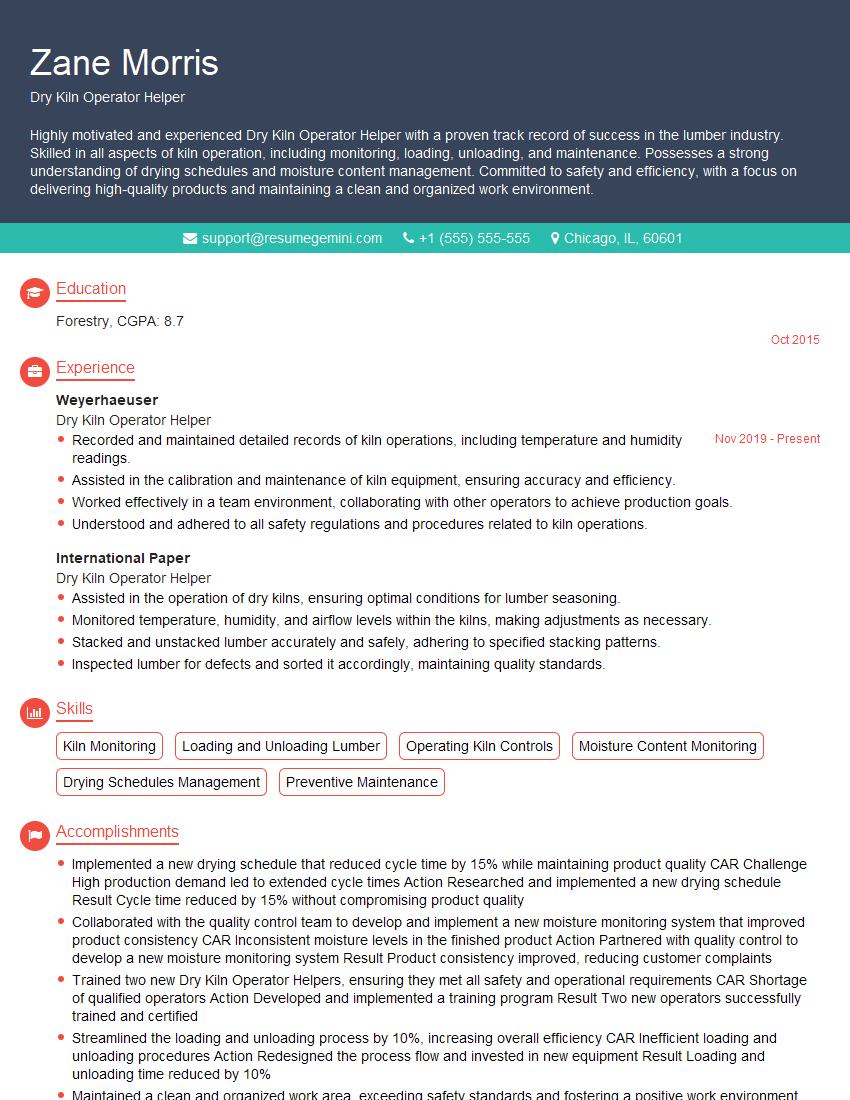

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Kiln Operator Helper

1. What is the purpose of a dry kiln?

A dry kiln is a chamber used to control the temperature and humidity of lumber in order to remove excess moisture from the wood. This process helps prevent warping, cracking, and other defects during the drying process.

2. What are the different types of dry kilns?

Conventional Dry Kiln

- Uses fans to circulate air within the chamber.

Convection Dry Kiln

- Uses heated air that naturally rises and circulates within the chamber.

Vacuum Dry Kiln

- Operates under vacuum conditions, which lowers the boiling point of water and accelerates drying.

Dehumidification Dry Kiln

- Controls humidity levels using a dehumidification system.

3. What are the key factors to consider when operating a dry kiln?

- Temperature and humidity levels

- Air circulation

- Load stacking patterns

- Species of wood being dried

4. What are the safety precautions to observe when working with a dry kiln?

- Wear appropriate personal protective equipment (PPE) such as gloves, eye protection, and a respirator.

- Follow established operating procedures to minimize risks.

- Be aware of potential hazards such as heat, humidity, and moving machinery.

5. How do you monitor and control the drying process?

- Use temperature and humidity sensors to monitor conditions within the kiln.

- Make adjustments to the kiln settings as needed to maintain desired conditions.

- Record and track kiln data regularly to ensure consistency and identify any potential issues.

6. How do you determine the moisture content of wood?

- Use a moisture meter to measure the electrical resistance of the wood, which is inversely proportional to its moisture content.

- Alternatively, use the oven-drying method to determine the moisture loss and calculate the moisture content.

7. What are the common defects that can occur during the drying process?

- Warping

- Cracking

- Checks

- Collapse

8. How do you prevent or minimize drying defects?

- Control drying conditions carefully.

- Use proper stacking patterns.

- Allow for adequate air circulation.

- Monitor the drying process closely and make adjustments as needed.

9. What are the different types of wood that can be dried in a dry kiln?

- Hardwoods, such as oak, maple, and mahogany

- Softwoods, such as pine, spruce, and fir

- Exotic woods, such as teak, ebony, and rosewood

10. What is your experience with troubleshooting dry kiln problems?

In my previous role, I encountered several issues with the dry kiln, including temperature fluctuations and uneven drying. I analyzed the kiln data, checked the equipment, and made adjustments to resolve the problems efficiently. I also conducted preventative maintenance to minimize future issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Kiln Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Kiln Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dry Kiln Operator Helpers are responsible for assisting Dry Kiln Operators in the operation and maintenance of dry kilns, which are used to dry lumber and other wood products.

1. Load and unload lumber

Loading and unloading lumber into and out of the dry kiln.

2. Monitor drying process

Monitoring the drying process and making adjustments to ensure that the lumber is drying properly.

3. Maintain equipment

Performing basic maintenance on the dry kiln equipment, such as cleaning and lubrication.

4. Other duties

Assisting with other tasks as needed, such as stacking lumber and preparing it for shipment.

Interview Tips

Preparing for an interview for a Dry Kiln Operator Helper position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company

Take some time to research the company you are applying to. This will help you understand their business, their culture, and their specific needs.

2. Practice your answers to common interview questions

There are a number of common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in the dry kiln industry. Be prepared to talk about your experience in detail, including your responsibilities, your accomplishments, and the skills you have developed.

4. Be positive and enthusiastic

The interviewer will be looking for someone who is positive and enthusiastic about the position. Be sure to convey your passion for the industry and your desire to learn and grow.

5. Dress professionally

First impressions matter, so be sure to dress professionally for your interview. This will show the interviewer that you are serious about the position and that you are respectful of their time.

6. Be on time

Punctuality is important, so be sure to arrive on time for your interview. This will show the interviewer that you are respectful of their time and that you are reliable.

7. Be yourself

The most important thing is to be yourself during your interview. The interviewer will be able to tell if you are being fake, so just relax and be yourself. This will help you build a rapport with the interviewer and increase your chances of success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Kiln Operator Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!