Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Forming Machine Upkeep Mechanic Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Forming Machine Upkeep Mechanic Helper so you can tailor your answers to impress potential employers.

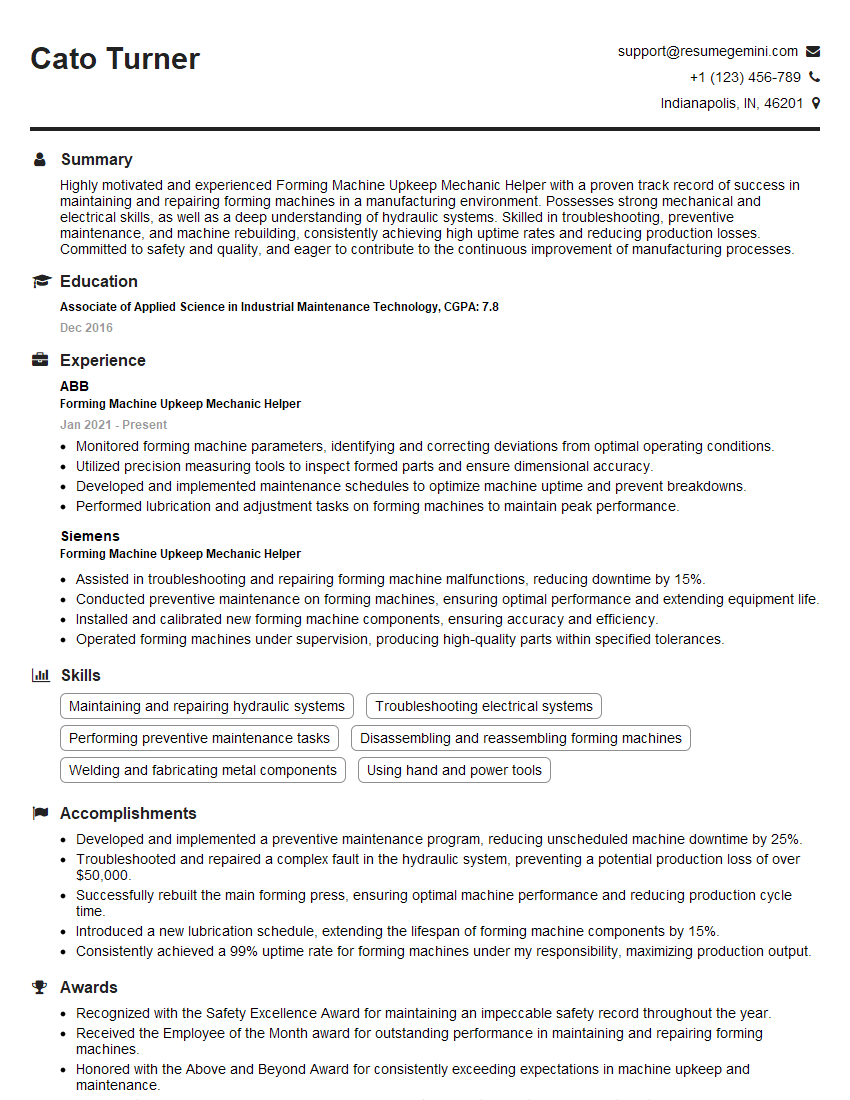

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forming Machine Upkeep Mechanic Helper

1. What are the key responsibilities of a Forming Machine Upkeep Mechanic Helper?

Some of the important responsibilities of Forming Machine Upkeep Mechanic Helper are:

- Assisting in the maintenance and repair of forming machines

- Monitoring the operation of forming machines and identifying any potential problems

- Cleaning and lubricating forming machines

- Replacing worn or damaged parts on forming machines

- Troubleshooting forming machine problems

- Maintaining a clean and safe work area

2. What are the different types of forming machines that you have experience with?

I have experience with a variety of forming machines, including:

Hydraulic forming machines

- Used to form metal into various shapes using hydraulic pressure

- Require knowledge of hydraulic systems and principles

Mechanical forming machines

- Use mechanical force to shape metal

- Require knowledge of mechanical systems and principles

CNC forming machines

- Computer-controlled forming machines

- Require knowledge of CNC programming and operation

3. What are the most common problems that you have encountered with forming machines?

Some of the most common problems that I have encountered with forming machines include:

- Leaking hydraulic fluid

- Worn or damaged parts

- Misaligned components

- Control system problems

- Electrical problems

4. How do you troubleshoot a forming machine problem?

When troubleshooting a forming machine problem, I typically follow these steps:

- Identify the symptoms of the problem

- Check for any obvious problems, such as loose connections or damaged parts

- Consult the machine’s manual or troubleshooting guide

- Use diagnostic tools to identify the source of the problem

- Repair or replace the faulty component

- Test the machine to ensure that the problem has been resolved

5. What are the safety precautions that you take when working on forming machines?

When working on forming machines, I always take the following safety precautions:

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs

- Lock out and tag out the machine before performing any maintenance or repairs

- Follow all safety procedures and guidelines

- Be aware of the potential hazards of working with forming machines

- Never operate a forming machine unless I am properly trained and authorized

6. What is your experience with preventative maintenance for forming machines?

I have experience developing and implementing preventative maintenance programs for forming machines. These programs typically include:

- Regular inspection and cleaning of machines

- Lubrication of moving parts

- Replacement of worn or damaged parts

- Calibration and adjustment of machines

- Monitoring of machine performance

7. What are your goals for this role?

My goals for this role are to:

- Learn as much as I can about forming machines and their maintenance

- Become a valuable member of the maintenance team

- Contribute to the efficient and safe operation of forming machines

- Advance my career in the field of machine maintenance

8. What are your strengths and weaknesses?

Strengths:

- Strong mechanical aptitude

- Good problem-solving skills

- Excellent communication and interpersonal skills

- Ability to work independently and as part of a team

- Willingness to learn and grow

Weaknesses:

- I am relatively new to the field of forming machine maintenance

- I sometimes have difficulty working under pressure

- I am not always the most organized person

9. Why do you think you are the best candidate for this role?

I believe that I am the best candidate for this role because I have the skills and experience necessary to be successful. I am a hard worker, I am eager to learn, and I am committed to safety. I am confident that I can make a valuable contribution to your team.

10. What is your availability?

I am available to start work immediately. I am flexible with my work schedule and I am willing to work overtime or on weekends if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forming Machine Upkeep Mechanic Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forming Machine Upkeep Mechanic Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forming Machine Upkeep Mechanic Helpers provide assistance to skilled mechanics by performing a variety of tasks related to the upkeep and maintenance of forming machines. These machines are used to shape and fabricate metal components and products. Key responsibilities include:

1. Assisting with Machine Repair and Maintenance

Helpers assist mechanics in repairing and maintaining forming machines. This includes tasks such as diagnosing problems, replacing parts, and making adjustments to ensure the machines are operating correctly.

- Replacing worn or damaged parts

- Adjusting machine settings to improve performance

- Performing preventive maintenance tasks

2. Conducting Inspections

Helpers conduct regular inspections of forming machines to identify any potential problems. They check for signs of wear and tear, leaks, and other issues that could affect the machine’s performance.

- Inspecting machines for signs of wear or damage

- Monitoring machine performance to identify potential problems

- Reporting any issues to the mechanic

3. Cleaning and Lubricating Machines

Helpers clean and lubricate forming machines to keep them in good working condition. This includes removing debris, applying lubricants, and cleaning electrical components.

- Cleaning machines to remove dirt, debris, and metal chips

- Lubricating moving parts to prevent wear and tear

- Cleaning electrical components to prevent short circuits

4. Troubleshooting Minor Problems

Helpers can troubleshoot minor problems with forming machines. They use their knowledge of the machines and their operation to identify the cause of the problem and take steps to resolve it.

- Identifying the cause of minor machine problems

- Troubleshooting and resolving simple issues

- Assisting mechanics with more complex repairs

Interview Tips

Preparing for an interview for a Forming Machine Upkeep Mechanic Helper position can increase the chances of making a good impression on the interviewer and landing the job. Here are some tips to help you prepare:

1. Research the Company and Position

Take the time to learn about the company’s industry, products, and services. Understanding the company’s culture and values will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages

- Read industry news and articles

- Learn about the specific role and responsibilities

2. Practice Your Answers

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Rehearsing your answers will help you feel more confident and prepared during the interview.

3. Highlight Relevant Skills and Experience

In your resume and interview, emphasize skills and experience that are relevant to the job, such as mechanical aptitude, attention to detail, and problem-solving skills. Provide specific examples of how you have used these skills in your previous work.

- Mechanical aptitude

- Attention to detail

- Problem-solving skills

- Customer service skills

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

5. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic about the position. Let your personality shine through and show the interviewer why you would be a great addition to their team.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Forming Machine Upkeep Mechanic Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.