Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Foundry Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

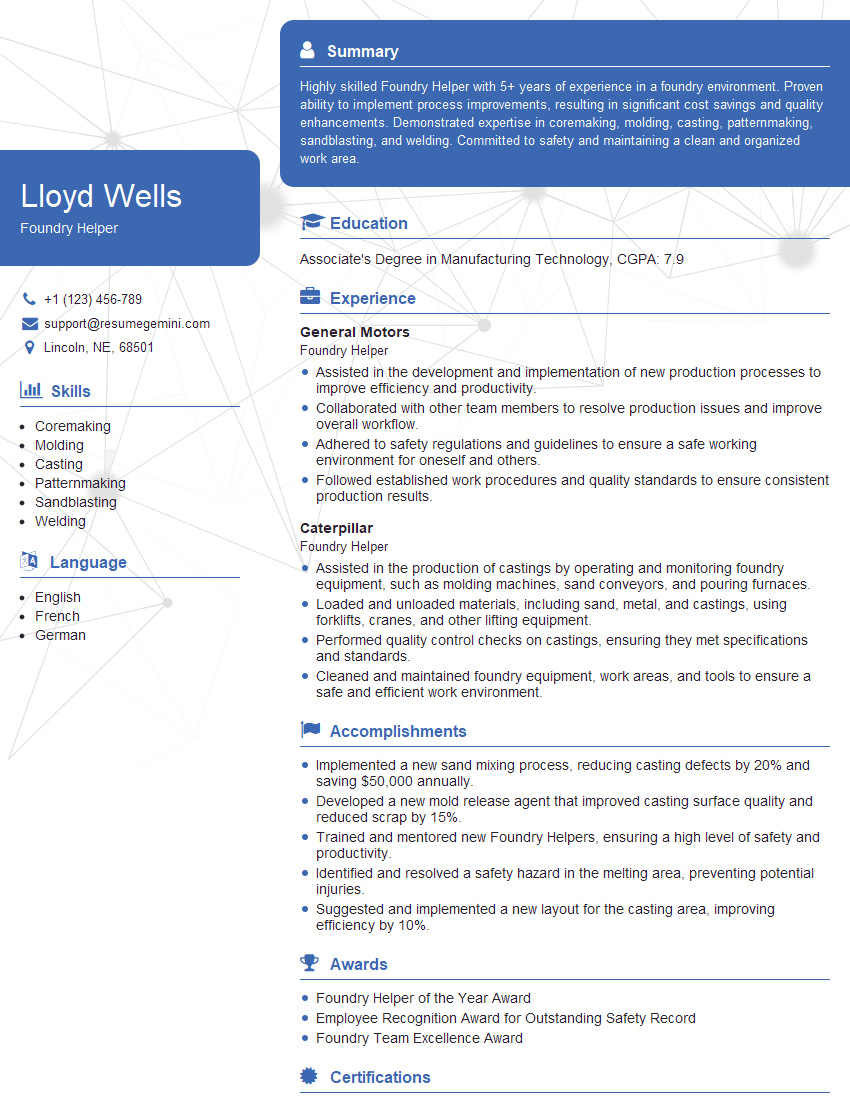

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Helper

1. Describe your experience in preparing foundry sand mixes?

- Explain the importance of proper sand mix preparation for producing quality castings.

- Highlight your knowledge of different sand types, binders, and additives used in foundry sand mixes.

- Describe the equipment and techniques used for sand mixing, such as mullers, mixers, and moisture controllers.

2. Explain the process of pouring molten metal into molds and how you ensure accurate pouring temperatures?

Safety Precautions

- Prioritize safety by wearing appropriate protective gear, including a face shield, gloves, and heat-resistant clothing.

- Maintain a safe work area, free from tripping hazards or flammable materials.

Accurate Pouring Temperatures

- Use calibrated equipment, such as thermocouples or optical pyrometers, to accurately measure molten metal temperatures.

- Understand the pouring temperature requirements for different metals and alloys.

- Adjust the temperature as necessary to prevent premature solidification or overheating.

3. How do you prepare and maintain mold equipment, including flasks, patterns, and core boxes?

- Inspect mold equipment for any damage or defects before use.

- Clean and apply mold release agents to ensure smooth casting removal.

- Maintain a clean and organized work area to prevent contamination.

- Lubricate moving parts of mold equipment regularly to ensure smooth operation.

4. Explain the different types of casting defects and how you identify and address them?

- Common casting defects such as porosity, shrinkage, cold shuts, and misruns.

- Identify the root causes of defects by analyzing casting appearance, sand quality, and pouring practices.

- Implement corrective actions, such as adjusting sand composition, improving gating systems, or modifying pouring techniques.

5. Describe the use of pneumatic tools and equipment in the foundry, emphasizing safety precautions

- Types of pneumatic tools used in a foundry, such as chipping hammers, grinders, and air hoists

- Safety precautions when using pneumatic tools, including wearing appropriate PPE, checking for leaks, and using guards.

- Proper maintenance and storage of pneumatic tools to ensure their safe operation.

6. How do you assist in the maintenance and repair of foundry equipment, ensuring production efficiency?

- Regularly inspect and monitor foundry equipment for potential issues.

- Report any observed problems promptly to supervisors or maintenance personnel.

- Assist in minor repairs and maintenance tasks, such as replacing worn parts or lubricating moving components.

- Follow established safety protocols and lockout/tagout procedures during maintenance.

7. Explain the importance of adhering to quality standards and procedures in foundry operations

- Benefits of adhering to quality standards, such as producing consistent and high-quality castings.

- Understanding and following established procedures, including those for sand preparation, melting, pouring, and post-casting operations.

- Using appropriate inspection techniques and equipment to ensure casting quality.

8. How do you work effectively as part of a foundry team, contributing to overall productivity?

- Understanding the importance of teamwork and collaboration in a foundry setting.

- Communicating effectively with team members to coordinate tasks and ensure smooth operations.

- Sharing knowledge and expertise with colleagues to enhance overall productivity.

9. Describe your experience in using foundry software or tools to support your work

- Knowledge of specialized foundry software for sand mix design, casting simulation, or quality control.

- Experience using measurement devices such as calipers, gauges, or coordinate measuring machines (CMMs).

- Ability to interpret foundry data and make informed decisions.

10. How do you stay updated with the latest advancements and best practices in the foundry industry?

- Attending industry conferences, workshops, or training programs.

- Reading technical publications and staying informed about new technologies and materials.

- Networking with other professionals in the foundry industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foundry Helpers assist with various tasks in a foundry, supporting the production of metal castings and related operations.

1. Material Handling

Responsible for moving, lifting, and transporting materials, such as sand, metal, and equipment.

- Loading and unloading materials from trucks, conveyors, and storage areas.

- Maintaining proper inventory and keeping work areas organized.

2. Equipment Operation

Assist in operating and maintaining foundry equipment, such as sand mixers, molding machines, and furnaces.

- Monitoring equipment performance and reporting any issues to superiors.

- Performing basic maintenance tasks, such as cleaning and lubricating equipment.

3. Mold Preparation

Assist in preparing and assembling molds for casting.

- Applying coatings and release agents to molds.

- Inserting cores and assembling mold components.

4. Pouring and Solidification

Assist in pouring molten metal into molds and monitoring the solidification process.

- Inspecting molds for defects before pouring.

- Ensuring proper cooling and handling of solidified castings.

Interview Tips

Preparing for a Foundry Helper interview requires a combination of technical knowledge, physical ability, and an understanding of the industry.

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and foundry operations. Research the specific role and its responsibilities to demonstrate your interest and understanding.

2. Highlight Physical Ability

Emphasize your physical strength, endurance, and ability to work in a fast-paced, physically demanding environment. Provide examples of previous work experience or training that demonstrate these qualities.

3. Technical Knowledge and Skills

Demonstrate your knowledge of foundry processes, equipment, and materials. If possible, provide examples of your experience with or interest in metalworking or manufacturing.

4. Safety Awareness

Emphasize your understanding of foundry safety protocols and regulations. Explain how you ensure safety in your work practices and how you would contribute to a safe work environment.

5. Teamwork and Collaboration

Foundry Helpers often work as part of a team. Highlight your ability to work effectively with others, communicate clearly, and contribute to a collaborative work environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Foundry Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.