Feeling lost in a sea of interview questions? Landed that dream interview for Kiln Drawer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Kiln Drawer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

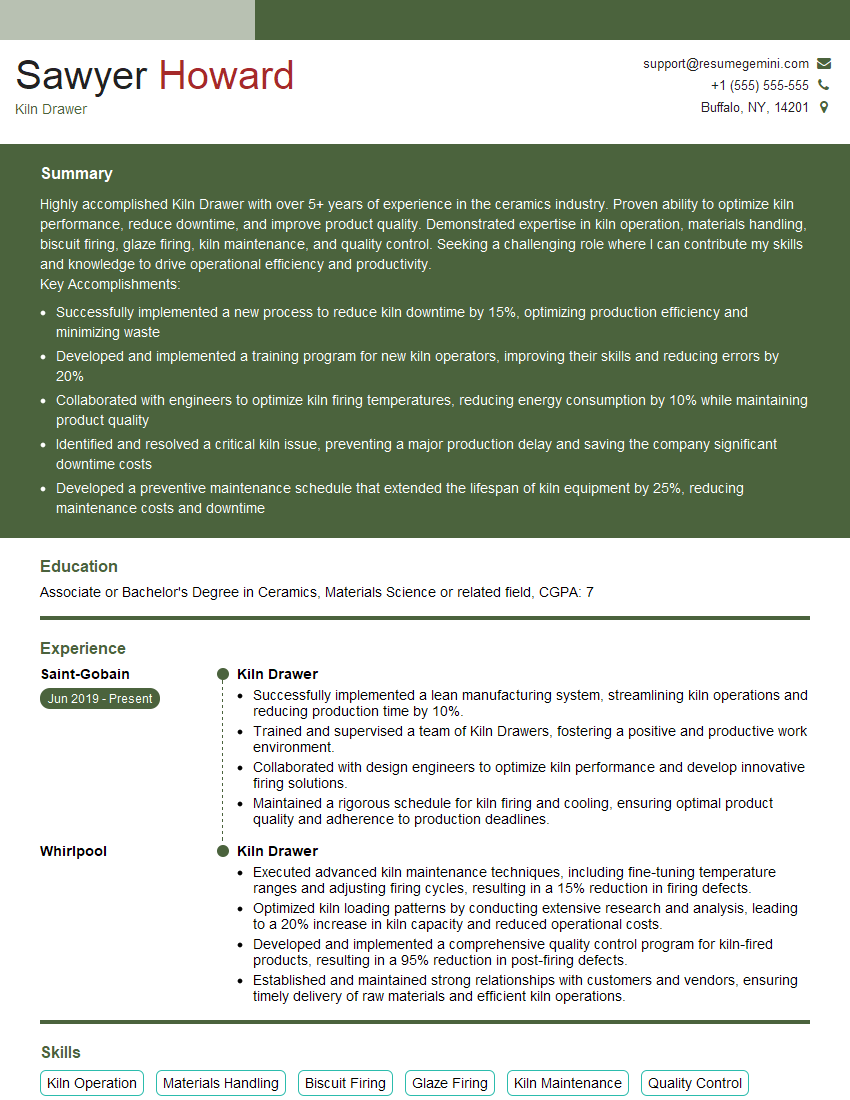

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Drawer

1. Explain the process of loading and unloading kilns?

- Wear appropriate personal protective equipment including heat-resistant gloves, safety glasses, and a mask.

- Inspect the kiln and work area for any potential hazards.

- Position the kiln car or shelves to the loading position.

- Carefully load the bisque ware onto the kiln shelves, ensuring that pieces are evenly spaced and not touching.

- Secure the load to prevent shifting during firing.

- Close the kiln door and seal it properly.

- Unload the kiln according to the manufacturer’s instructions, once the firing cycle is complete.

- Allow the kiln to cool before unloading.

- Wear appropriate personal protective equipment when unloading the kiln.

- Carefully remove the fired ware from the kiln shelves.

- Inspect the fired ware for any defects.

- Store the fired ware in a safe and dry place.

2. How do you maintain and troubleshoot kilns?

Daily Maintenance:

- Check the kiln interior for any damage or debris.

- Clean the kiln elements and thermocouple.

- Inspect the kiln door and seals for any damage.

- Lubricate the kiln car or shelves.

Weekly Maintenance:

- Calibrate the kiln controller.

- Check the kiln insulation for any damage.

- Inspect the electrical connections.

Troubleshooting:

- Overheating: Check the elements, thermocouple, and controller.

- Underheating: Check the elements, thermocouple, and controller.

- Uneven heating: Check the element placement and insulation.

- Cracking: Check the ware placement, load density, and firing schedule.

- Bloating: Check the clay body composition, moisture content, and firing schedule.

3. How do you ensure the quality of fired ware?

- Use high-quality materials and glazes.

- Follow the manufacturer’s firing instructions carefully.

- Monitor the kiln temperature and atmosphere throughout the firing cycle.

- Inspect the fired ware for any defects.

- Store the fired ware in a safe and dry place.

- Keep a record of each firing, including the ware, firing schedule, and results.

4. What are the safety precautions that need to be followed when working with kilns?

- Wear appropriate personal protective equipment including heat-resistant gloves, safety glasses, and a mask.

- Never touch the kiln or its contents while it is hot.

- Keep the kiln area well-ventilated.

- Do not store flammable materials near the kiln.

- Turn off the kiln and allow it to cool before making any repairs.

- Be aware of the potential for kiln explosions and take appropriate precautions.

5. What are the different types of kilns and their uses?

- Electric kilns: Use electricity as a heat source. They are commonly used in studios and schools because they are relatively easy to use and maintain.

- Gas kilns: Use gas as a heat source. They are often used in industrial settings because they can reach higher temperatures than electric kilns.

- Wood-fired kilns: Use wood as a heat source. They are often used by artists who want to create unique and rustic-looking pieces.

- Raku kilns: Use a combination of gas and wood as a heat source. They are often used to create low-fired, smoke-decorated pieces.

6. What are the different firing schedules for different types of clay?

- Earthenware: Fired at temperatures between 1000-1200°C (1832-2192°F).

- Stoneware: Fired at temperatures between 1200-1300°C (2192-2372°F).

- Porcelain: Fired at temperatures between 1300-1400°C (2372-2552°F).

7. What are the different types of glazes and their uses?

- Clear glazes: Allow the color of the clay body to show through.

- Opaque glazes: Create a solid color on the surface of the clay.

- Matte glazes: Create a non-glossy surface.

- Glossy glazes: Create a shiny surface.

- Crystalline glazes: Create a surface with visible crystals.

8. How do you calculate the cost of firing a kiln?

- Calculate the volume of the kiln in cubic feet.

- Determine the cost of electricity or gas per kilowatt-hour or cubic foot.

- Multiply the volume of the kiln by the cost of electricity or gas.

- Add the cost of materials, such as kiln shelves and glaze.

- Divide the total cost by the number of pieces fired.

9. What are the environmental regulations that apply to kiln operation?

- The Clean Air Act:

- The Resource Conservation and Recovery Act:

- The Comprehensive Environmental Response, Compensation, and Liability Act:

- The Emergency Planning and Community Right-to-Know Act:

- The Toxic Substances Control Act:

10. What are the career opportunities for Kiln Drawer?

- Kiln Operator

- Ceramic Production Technician

- Ceramic Engineer

- Art Teacher

- Studio Potter

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Drawer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Drawer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Kiln Drawer

Kiln Drawers play a crucial role in the ceramics industry, ensuring the safe and efficient unloading of fired ceramics from kilns. Their key responsibilities include:

1. Unloading Kilns

Kiln Drawers are responsible for unloading kilns once the firing process is complete. They carefully extract fired ceramics using specialized tools, such as kiln shelves and tongs, ensuring the preservation of delicate pieces.

2. Inspecting Fired Ceramics

Upon unloading, Kiln Drawers inspect the fired ceramics for any defects or damage. They assess the quality and appearance of the pieces, ensuring they meet the required standards and specifications.

3. Cleaning Kilns

After unloading, Kiln Drawers clean and maintain the kilns. They remove excess glaze, debris, and kiln furniture to prepare the kiln for the next firing cycle, ensuring optimal performance and safety.

4. Loading Kilns

In some cases, Kiln Drawers may also assist in loading kilns with unfired ceramics. They carefully place the pieces on kiln shelves, ensuring proper spacing and support to prevent damage during firing.

5. Monitoring Kiln Temperatures

Kiln Drawers may assist in monitoring kiln temperatures during the firing process. They ensure that the temperature remains within the desired range, contributing to the successful firing of ceramics.

Interview Tips for Kiln Drawer Candidates

Preparing for a Kiln Drawer interview requires a combination of technical knowledge and soft skills. Here are some tips to help candidates ace their interview:

1. Research the Company and Position

Thoroughly research the company and the specific kiln drawer position. Familiarize yourself with their products, processes, and safety protocols. This demonstrates your enthusiasm and commitment to the role.

2. Highlight Relevant Experience

Emphasize your experience in handling delicate materials, inspecting products, and maintaining equipment. Share examples of your attention to detail and ability to work safely in a kiln environment.

3. Understand Kiln Operation

Demonstrate your understanding of kiln operation, including loading, unloading, and temperature monitoring. Explain how you would ensure the safe and efficient use of kilns.

4. Practice Your Communication Skills

Kiln Drawers interact with other team members, supervisors, and clients. Practice your communication skills to effectively convey information, ask questions, and collaborate with others.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer about the company, the position, and the industry. This shows your engagement and interest in the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Kiln Drawer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Kiln Drawer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.