Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Iron Molder Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

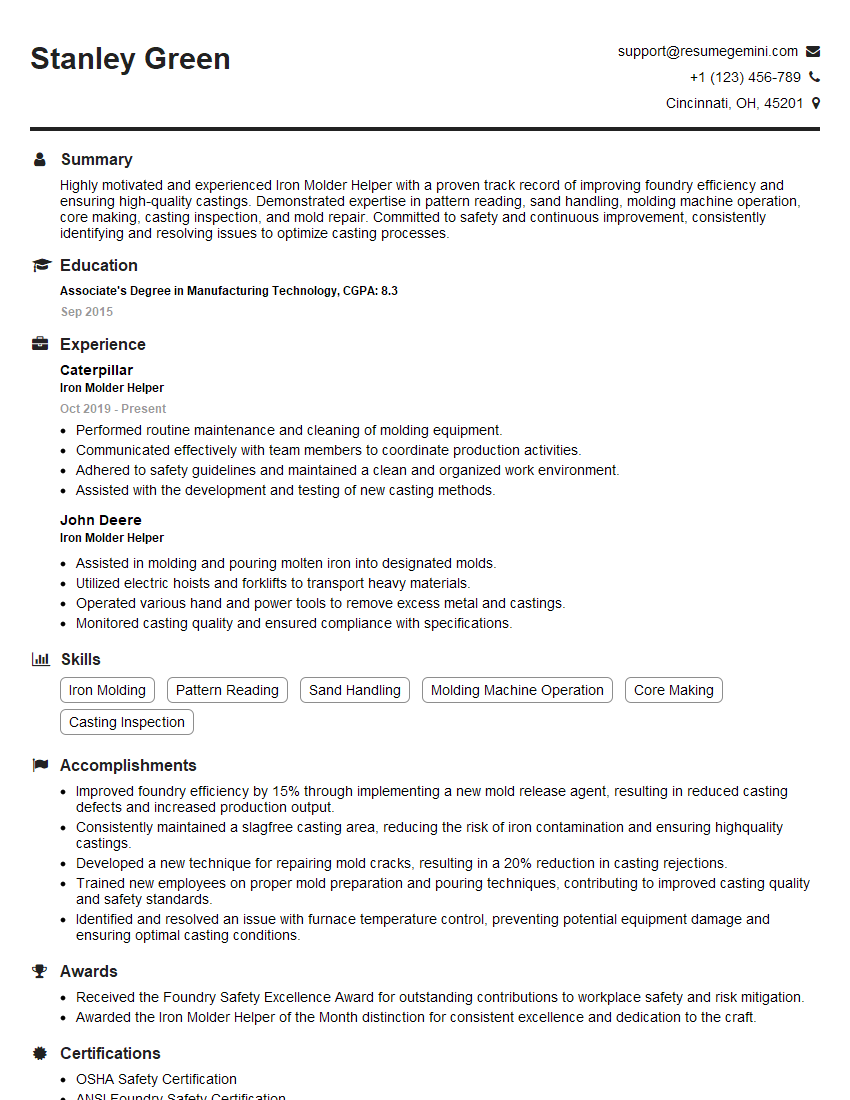

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Iron Molder Helper

1. What is the role of an Iron Molder Helper?

As an Iron Molder Helper, I would be responsible for assisting the Iron Molder with a variety of tasks, including:

- Preparing and maintaining molds and equipment

- Loading and unloading molten metal into molds

- Removing castings from molds

- Finishing and inspecting castings

- Maintaining a clean and safe work area

2. What experience do you have with molding and casting processes?

Experience with Molding Processes

- I have experience in a variety of molding processes, including sand casting, investment casting, and permanent mold casting.

- I am familiar with the different types of molds and molding materials used in each process.

- I have experience in preparing and maintaining molds, including creating patterns, making cores, and assembling molds.

Experience with Casting Processes

- I have experience in a variety of casting processes, including ferrous and non-ferrous casting.

- I am familiar with the different types of furnaces and casting equipment used in each process.

- I have experience in pouring molten metal into molds and removing castings from molds.

3. Can you explain the steps involved in sand casting?

Sand casting is a metal casting process that uses sand as the mold material. The steps involved in sand casting are as follows:

- Patternmaking: A pattern is made of the desired casting. The pattern is typically made of wood or metal.

- Molding: The pattern is used to create a mold in the sand. The mold is made by packing sand around the pattern and then removing the pattern.

- Coremaking: Cores are used to create hollow spaces in the casting. Cores are made by forming sand around a pattern and then baking the sand to harden it.

- Assembling the mold: The mold is assembled by placing the cope and drag halves of the mold together. The cope is the top half of the mold, and the drag is the bottom half of the mold.

- Pouring: Molten metal is poured into the mold. The metal fills the mold and solidifies.

- Shakeout: After the metal has solidified, the mold is shaken out to remove the casting. The casting is then cleaned and inspected.

4. What are the safety precautions that must be taken when working with molten metal?

- Wear appropriate personal protective equipment, including flame-resistant clothing, gloves, and safety glasses.

- Keep a safe distance from molten metal.

- Never pour molten metal into a wet or damp mold.

- Be aware of the potential for explosions when molten metal comes into contact with water.

- Have a fire extinguisher nearby in case of a fire.

- Follow all safety procedures and guidelines established by your employer.

5. How do you maintain and troubleshoot casting equipment?

- Perform regular inspections of all casting equipment.

- Identify and repair any worn or damaged parts.

- Lubricate all moving parts according to the manufacturer’s instructions.

- Troubleshoot any problems that arise with the casting equipment.

- Keep a maintenance log to track all repairs and maintenance performed on the casting equipment.

6. What are the different types of casting defects and how can they be prevented?

Types of Casting Defects

- Shrinkage defects: These defects are caused by the metal shrinking as it cools. Shrinkage defects can be prevented by using a mold that is designed to compensate for the shrinkage of the metal.

- Gas defects: These defects are caused by gases that are trapped in the metal as it solidifies. Gas defects can be prevented by using a mold that is designed to allow gases to escape.

- Inclusion defects: These defects are caused by foreign objects that are trapped in the metal as it solidifies. Inclusion defects can be prevented by using clean materials and by filtering the molten metal before it is poured into the mold.

- Mold defects: These defects are caused by problems with the mold. Mold defects can be prevented by using a mold that is properly designed and maintained.

Preventing Casting Defects

- Use a mold that is designed to compensate for the shrinkage of the metal.

- Use a mold that is designed to allow gases to escape.

- Use clean materials and filter the molten metal before it is poured into the mold.

- Use a mold that is properly designed and maintained.

7. What experience do you have with quality control in a foundry?

- I have experience in a variety of quality control procedures used in a foundry, including:

- Visual inspection of castings

- Dimensional inspection of castings

- Hardness testing of castings

- Destructive testing of castings

- I am familiar with the different quality standards used in the foundry industry, including ASTM, ISO, and MIL-SPEC.

- I have experience in developing and implementing quality control plans.

8. What are the different types of molding materials and how are they used?

- Sand: Sand is the most common molding material. It is inexpensive and can be used to create a variety of mold shapes.

- Investment: Investment is a type of molding material that is made of a ceramic slurry. Investment molds are very accurate and can be used to create complex castings.

- Permanent mold: Permanent molds are made of metal or graphite. They are used to create high-volume castings.

- Shell mold: Shell molds are made of a thin layer of sand that is coated with a resin. Shell molds are lightweight and can be used to create complex castings.

9. Explain the sand casting process.

The sand casting process begins with the creation of a pattern. The pattern is a replica of the desired casting. The pattern is then used to create a mold in the sand. The mold is made by packing sand around the pattern and then removing the pattern.

Once the mold is created, it is filled with molten metal. The molten metal solidifies in the mold, creating a casting. The casting is then removed from the mold and cleaned.

10. What are the different types of furnaces used in foundries?

- Induction furnace: Induction furnaces use an electromagnetic field to heat and melt metal.

- Arc furnace: Arc furnaces use an electric arc to heat and melt metal.

- Cupolas: Cupolas are used to melt iron and steel.

- Reverbatory furnaces: Reverbatory furnaces use a flame to heat and melt metal.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Iron Molder Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Iron Molder Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Iron Molder Helpers play a crucial role in foundries and metalworking facilities. Their primary responsibilities include:

1. Assisting with Mold Creation

Assisting skilled iron molders in preparing and assembling molds for casting metal objects.

- Mixing and pouring molding materials (e.g., sand, binders, additives)

- Creating patterns and shapes in the mold using various techniques (e.g., ramming, jolting)

2. Handling Molten Metal

Safely handling and transporting molten metal from furnaces to molds.

- Operating pouring ladles or other equipment to pour molten metal

- Ensuring proper temperature and flow of molten metal

3. Maintaining Equipment and Workspace

Maintaining and cleaning equipment, tools, and the work area to ensure optimal functioning and safety.

- Inspecting and maintaining equipment (e.g., mixers, molders, conveyors)

- Cleaning and organizing the work area to eliminate hazards and improve efficiency

4. Assisting with Finishing Processes

Assisting with the removal of castings from molds and performing finishing operations.

- Breaking apart molds and extracting castings

- Performing initial cleaning and inspection of castings

Interview Tips

Preparing for an Iron Molder Helper interview requires careful consideration and preparation. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Demonstrate your interest and understanding of the company’s operations and the metalworking industry. Research the company’s history, products, and reputation to show that you have taken the initiative to learn about the potential employer.

- Visit the company website and LinkedIn page

- Read industry publications and news articles

2. Study the Job Description

Carefully analyze the job description to identify the key responsibilities and qualifications required for the role. Highlight your skills and experience that align with these requirements in your resume and during the interview.

- Identify the core duties and responsibilities

- Note specific skills and qualifications mentioned

3. Practice Answering Common Interview Questions

Prepare for commonly asked interview questions related to the role, your skills, and your career goals. Practice your answers aloud to gain confidence and ensure clear delivery during the interview.

- “Tell us about your experience working with molten metal.”

- “How do you ensure the safety of yourself and others in a foundry environment?”

4. Highlight Your Physical Strength and Endurance

The job requires physical strength and endurance to perform tasks such as lifting heavy objects and handling molten metal. Emphasize your physical abilities and any relevant experience in physically demanding work environments.

- Explain any previous work where you handled heavy materials

- Describe your fitness routine or any physical activities that demonstrate your endurance

5. Show Your Commitment to Safety

Foundries prioritize safety due to the potential hazards involved. Demonstrate your understanding of safety regulations and procedures by providing examples of your commitment to following safety guidelines and maintaining a safe work environment.

- Share any safety certifications or training you have received

- Explain how you prioritize safety in your personal life and previous work experiences

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Iron Molder Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Iron Molder Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.