Are you gearing up for an interview for a Liner Machine Operator Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Liner Machine Operator Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

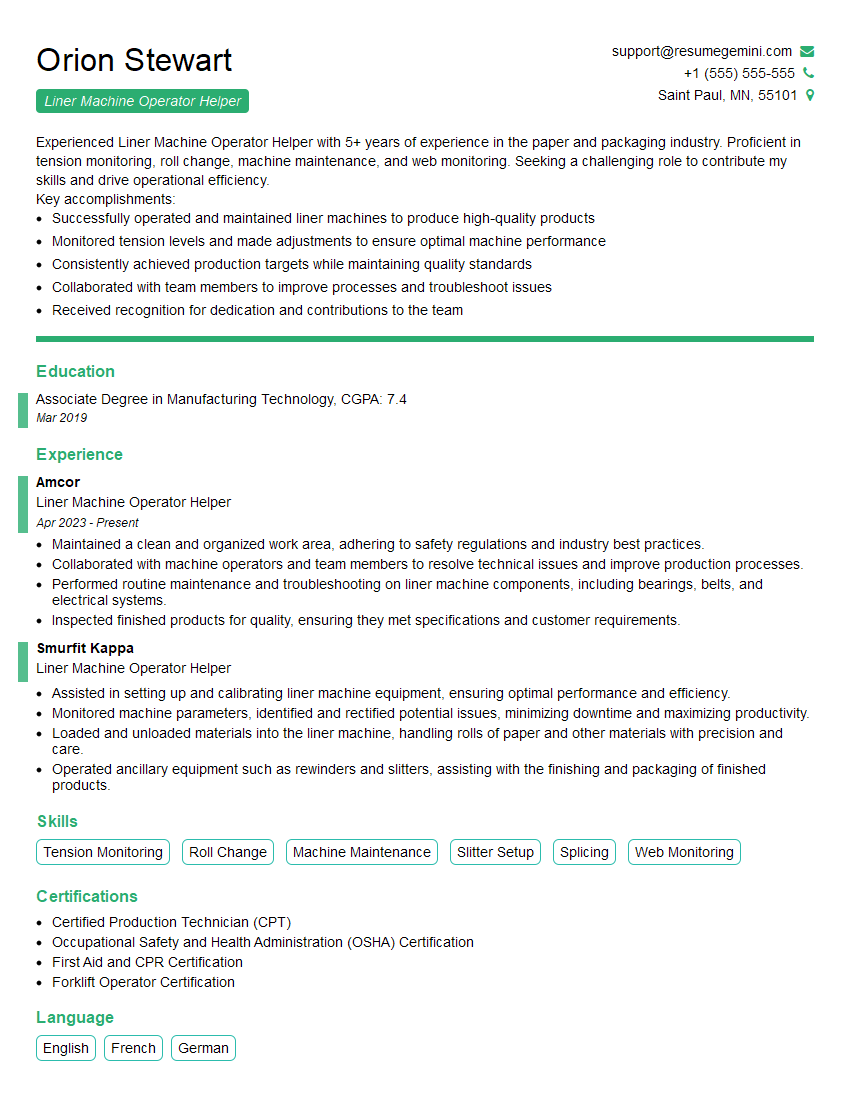

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liner Machine Operator Helper

1. What are the key responsibilities of a Liner Machine Operator Helper?

- Assisting the Liner Machine Operator in the production of paperboard liners.

- Monitoring the machine’s operation and making adjustments as needed.

2. What is the process for threading the linerboard machine?

Pre-Threading:

- Inspect the linerboard roll for any damage or defects.

- Load the linerboard roll onto the unwind stand.

Threading:

- Start the unwind stand and guide the linerboard through the machine.

- Thread the linerboard through the preheater, size press, and dryers.

- Align the linerboard with the reel and start winding.

3. What are the different types of paperboard liners?

- Kraft linerboard: Strong and durable, used for corrugated boxes and packaging.

- Test linerboard: Smoother surface, used for higher-quality printing applications.

- Chipboard linerboard: Made from recycled paper, used for low-cost packaging.

4. How do you maintain the liner machine to ensure optimal performance?

- Regularly inspect and clean the machine components.

- Lubricate moving parts as per the manufacturer’s instructions.

- Check and adjust the machine settings to minimize downtime.

- Follow proper shutdown and startup procedures.

5. What safety precautions should be taken when working on the liner machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Be aware of moving parts and potential hazards.

- Follow lockout/tagout procedures when working on the machine.

- Report any safety concerns to the supervisor immediately.

6. What are the common problems that can occur during liner production?

- Wrinkles or creases in the linerboard.

- Uneven coating or adhesive application.

- Paper breaks or machine jams.

- Variations in linerboard thickness or caliper.

7. How do you troubleshoot and resolve these problems?

- Identify the root cause of the problem.

- Make necessary adjustments to the machine settings or operating procedures.

- Inspect and replace worn or damaged parts.

- Consult with the supervisor or maintenance team if the issue cannot be resolved.

8. What is the role of quality control in liner production?

- Monitoring the linerboard quality throughout the production process.

- Performing regular tests to ensure the linerboard meets specifications.

- Identifying and addressing quality issues promptly.

- Maintaining quality records and reporting on the linerboard’s performance.

9. What are the key performance indicators (KPIs) used to measure the efficiency of the liner machine?

- Production output (tons/hour)

- Machine uptime (%)

- Paper breaks (per 1000 tons)

- Linerboard quality (conformance to specifications)

10. How do you contribute to continuous improvement in the liner production process?

- Participating in quality improvement initiatives.

- Suggesting process improvements or equipment upgrades.

- Documenting best practices and sharing knowledge with colleagues.

- Staying updated on industry trends and advancements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liner Machine Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liner Machine Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Liner Machine Operator Helper plays a crucial role in supporting the efficient operation of the liner machine in a corrugated cardboard manufacturing facility.

1. Machine Operation

Assists in the operation of the liner machine, monitoring and making adjustments as needed to maintain optimal performance.

2. Material Handling

Handles and moves heavy rolls of paper and other materials, ensuring they are properly loaded and unloaded from the machine.

3. Maintenance and Cleaning

Participates in routine maintenance and cleaning of the liner machine, ensuring its smooth functioning and minimizing downtime.

4. Production Monitoring

Monitors production output, identifying and addressing any potential issues to maintain quality and efficiency.

Interview Tips

To ace your interview for the Liner Machine Operator Helper position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s industry, size, and values. Research the specific role and its responsibilities to demonstrate your understanding of the position.

2. Highlight Relevant Experience

Emphasize previous experience in a manufacturing or production environment, particularly if it involved handling heavy materials or operating machinery.

3. Demonstrate Attention to Detail

Convey your meticulous nature by providing examples of your ability to pay attention to details and ensure accuracy in your work.

4. Show Enthusiasm for Teamwork

Express your eagerness to collaborate with others and contribute to a team-oriented environment, as the role involves working closely with other machine operators.

5. Be Prepared for Physical Requirements

Acknowledge the physical demands of the role, indicating your ability to handle heavy lifting and extended periods of standing or walking.

Next Step:

Now that you’re armed with the knowledge of Liner Machine Operator Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Liner Machine Operator Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini