Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lining Scrubber interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lining Scrubber so you can tailor your answers to impress potential employers.

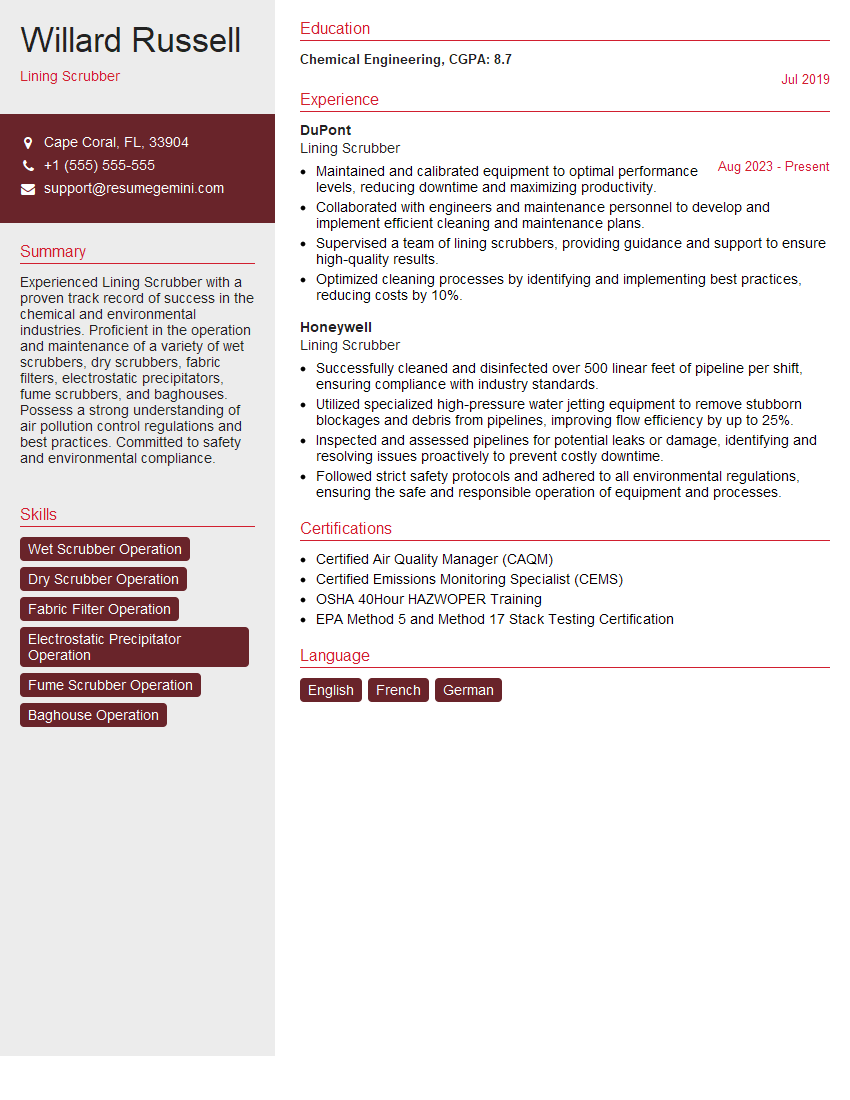

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lining Scrubber

1. How do you determine the appropriate water pressure for lining scrubbing?

To determine the appropriate water pressure for lining scrubbing, consider several factors:

- Type of lining material: Different lining materials have different pressure tolerances. Sensitive linings require lower pressures, while more durable linings can withstand higher pressures.

- Condition of the lining: If the lining is heavily scaled or fouled, higher pressures may be necessary to remove the buildup effectively.

- Nozzle size and type: The nozzle size and type determine the water flow rate and impact force. Larger nozzles with higher flow rates require higher pressures to maintain optimal performance.

- Safety considerations: Excessively high pressures can damage the lining or pose a safety hazard. It’s crucial to follow manufacturer recommendations and industry guidelines for water pressure.

2. Describe the different types of lining scrubbing nozzles and their applications.

- Flat fan nozzles: Produce a wide, flat spray pattern, suitable for general-purpose cleaning and removing light to moderate fouling.

- Rotary nozzles: Spin rapidly, creating a concentrated, high-impact spray for removing heavy scale and buildup.

- Rotating nozzles: Combine the features of flat fan and rotary nozzles, providing a wide spray pattern with high impact for effective cleaning in challenging conditions.

- Nozzle holders: Hold the nozzles in place and allow for adjustment of the spray angle and direction.

3. Explain the importance of maintaining proper chemical concentration in a lining scrubbing system.

- Ensures effective removal of fouling and scale.

- Prevents excessive corrosion or damage to the lining.

- Reduces the risk of chemical overdosing, which can be hazardous and environmentally damaging.

- Optimizes chemical usage, minimizing costs and environmental impact.

4. Describe the safety precautions to be taken when handling and using chemicals for lining scrubbing.

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator if necessary.

- Follow manufacturer’s instructions for proper handling, storage, and disposal of chemicals.

- Avoid skin contact with chemicals and rinse thoroughly if exposed.

- Keep chemicals away from open flames or ignition sources.

- Have emergency spill response procedures in place.

5. How do you troubleshoot common problems encountered during lining scrubbing?

- Nozzle clogging: Check for debris or scale buildup in the nozzles and clean accordingly.

- Low water pressure: Verify that the pump is operating correctly and that there are no blockages in the water supply line.

- Insufficient chemical concentration: Test the chemical concentration and adjust as necessary.

- Damaged lining: Inspect the lining for any cracks, holes, or other damage that may affect the effectiveness of the scrubbing process.

- Environmental factors: Consider external factors such as temperature, humidity, and wind speed that may impact the performance of the lining scrubbing system.

6. Explain the importance of regular lining inspections and maintenance.

- Extend lining life: Regular inspections and maintenance help identify potential problems early on, allowing for timely repairs and reducing the risk of costly failures.

- Maintain optimal performance: Lining scrubbing removes buildup and fouling, ensuring that the lining functions efficiently.

- Safety: Inspections can detect lining damage or deterioration that could pose safety hazards.

- Cost savings: Proactive maintenance prevents major repairs or replacements, saving costs in the long run.

7. Describe the different methods used to clean and disinfect lining scrubbing equipment.

- Physical cleaning: Disassemble the equipment and manually remove dirt, debris, or scale buildup.

- Chemical cleaning: Use cleaning solutions or detergents to remove chemical residues and fouling.

- Disinfection: Apply disinfectants to kill microorganisms, such as bacteria or mold, to prevent contamination.

8. Explain the importance of following manufacturer’s instructions when operating and maintaining lining scrubbing equipment.

- Safety: Following instructions ensures safe operation and prevents accidents.

- Optimal performance: Using the equipment as intended maximizes its effectiveness and efficiency.

- Warranty protection: Proper operation and maintenance are essential for maintaining warranty coverage.

- Extended lifespan: Correct usage and maintenance prolongs the equipment’s lifespan.

9. Describe the different types of lining materials and their compatibility with lining scrubbing chemicals.

- Glass-lined steel: Resistant to most acids and chemicals, but susceptible to abrasion.

- Rubber-lined steel: Flexible and resistant to abrasion, but not suitable for all chemicals.

- Epoxy-coated steel: Chemically resistant and easy to clean, but can be damaged by mechanical impact.

- Polypropylene: Lightweight and resistant to acids and bases, but not suitable for high temperatures.

10. Explain the environmental regulations and industry best practices related to lining scrubbing.

- Wastewater discharge: Follow regulations on the discharge of wastewater containing chemicals or solids.

- Chemical storage and disposal: Adhere to safety guidelines and regulations for the storage and disposal of lining scrubbing chemicals.

- Equipment maintenance and calibration: Ensure that equipment is properly maintained, calibrated, and operated to minimize environmental impact.

- Training and certification: Operators should be trained and certified in the safe and responsible use of lining scrubbing equipment and chemicals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lining Scrubber.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lining Scrubber‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lining Scrubber is responsible for cleaning and maintaining the linings of process equipment and piping systems in various industries such as pharmaceutical, chemical, and food and beverage. Their primary duties include:

1. Equipment Cleaning and Maintenance

Cleaning and scrubbing the internal surfaces of process equipment, including tanks, reactors, pipelines, and vessels.

- Removing product residues, contaminants, and other impurities from equipment linings.

- Ensuring the cleanliness and sterility of equipment to meet industry standards and regulations.

2. Lining Inspection and Repair

Inspecting linings for damage, wear, or defects.

- Repairing or replacing damaged linings using specialized techniques and materials.

- Maintaining the integrity and functionality of process equipment linings.

3. Chemical Handling and Safety

Handling and using various cleaning chemicals, solvents, and detergents.

- Following safety protocols and regulations for chemical handling.

- Protecting themselves and others from hazardous substances.

4. Quality Control and Documentation

Maintaining quality standards by adhering to established cleaning and maintenance procedures.

- Documenting cleaning and maintenance activities, including records of chemicals used, inspection results, and repairs made.

- Ensuring compliance with industry regulations and best practices.

Interview Tips

To ace the interview for a Lining Scrubber position, candidates should:

1. Research the Company and Industry

Glean information about the company’s products, services, and industry reputation.

- This demonstrates your interest in the role and your ability to hit the ground running.

- Tailor your answers to show how you can specifically contribute to the company’s goals.

2. Highlight Relevant Experience and Skills

Emphasize your previous experience in cleaning and maintaining process equipment linings.

- Quantify your accomplishments using specific metrics to showcase your impact.

- Share examples of your problem-solving abilities and attention to detail.

3. Demonstrate Knowledge of Cleaning Techniques

Explain your understanding of various cleaning techniques and chemicals used for lining maintenance.

- Discuss your experience with specialized cleaning equipment or technologies.

- Highlight your ability to work independently and as part of a team.

4. Emphasize Safety and Quality Assurance

Stress your commitment to safety and quality control in your work.

- Share examples of your adherence to safety protocols and industry regulations.

- Explain your understanding of quality assurance standards and documentation procedures.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lining Scrubber, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lining Scrubber positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.