Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Manual Plate Filler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Manual Plate Filler so you can tailor your answers to impress potential employers.

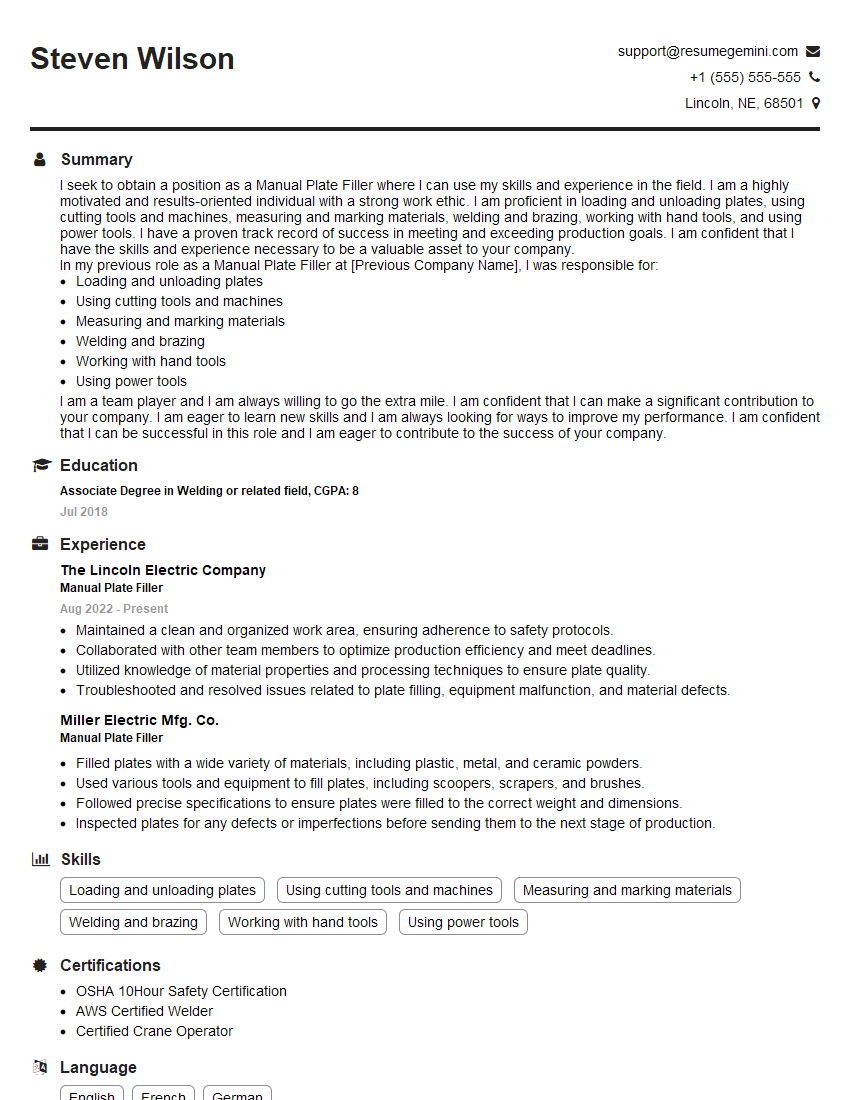

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manual Plate Filler

1. Describe the key responsibilities of a Manual Plate Filler.

As a Manual Plate Filler, I would be responsible for:

- Manually filling plates with various materials, ensuring precise weight and accuracy.

- Operating and maintaining filling machines, ensuring they are calibrated and functioning properly.

- Monitoring the filling process, identifying and resolving any issues promptly.

- Maintaining a clean and organized work area, adhering to safety protocols.

- Collaborating with production teams to meet production targets and quality standards.

2. How do you ensure the accuracy and consistency of plate filling?

Consistency in Material Handling

- I would carefully follow standardized filling procedures and use calibrated equipment to ensure consistent material handling.

- I would pay attention to details such as material properties, temperature, and flow rate to maintain accuracy.

Regular Calibration

- I would regularly calibrate filling machines according to manufacturer’s guidelines to maintain their precision.

- I would also conduct regular self-inspections and report any deviations or issues to ensure accuracy.

3. How do you handle and resolve common issues that may arise during the plate filling process?

During the plate filling process, I would anticipate and handle common issues proactively:

- Material blockages: I would identify the cause of blockages, such as material clumping or equipment malfunctions, and promptly clear them.

- Inconsistent filling: I would check equipment settings, material properties, and filling techniques to identify and address any inconsistencies.

- Leaking or spills: I would inspect equipment for leaks or damage and take immediate action to contain and clean up spills.

- Equipment malfunctions: I would follow troubleshooting procedures, identify the source of malfunctions, and report them for prompt repair or replacement.

4. How do you maintain a safe and clean work environment in a plate filling facility?

Maintaining a safe and clean work environment is crucial:

- Equipment safety: I would ensure that all filling machines are properly guarded and operated safely.

- Material handling safety: I would follow designated protocols for handling various materials, including proper storage, transportation, and disposal.

- Housekeeping: I would regularly clean and organize the work area, disposing of waste materials and maintaining a tidy environment.

- Personal safety: I would wear appropriate personal protective equipment (PPE) and adhere to safety guidelines to prevent accidents or injuries.

5. How do you prioritize tasks and manage your time effectively in a fast-paced production environment?

In a fast-paced production environment, I would prioritize tasks based on the following factors:

- Urgency: I would prioritize tasks that require immediate attention to avoid production delays.

- Impact: I would focus on tasks that have a significant impact on production output or quality.

- Dependencies: I would identify tasks that are dependent on others and ensure their timely completion.

I would also utilize effective time management techniques such as:

- Time blocking: I would allocate specific time slots for different tasks to maintain focus and efficiency.

- Prioritization matrix: I would use a matrix to categorize tasks based on urgency and importance.

- Delegation: When necessary, I would delegate tasks to other team members to optimize productivity.

6. How do you ensure that the filled plates meet the required specifications and quality standards?

To ensure that the filled plates meet the required specifications and quality standards, I would:

- Verify material specifications: I would check material properties, such as weight, dimensions, and composition, to ensure they comply with the specified requirements.

- Follow filling procedures: I would strictly adhere to established filling procedures to maintain consistent quality.

- Inspect filled plates: I would visually inspect filled plates to ensure they are free from defects, such as underfilling, overfilling, or damage.

- Record and report: I would accurately record filling data and report any deviations or non-conformances to ensure prompt corrective actions.

7. How do you handle situations where you are not sure how to proceed with a particular plate filling task?

In situations where I am unsure how to proceed with a particular plate filling task, I would take the following steps:

- Refer to documentation: I would consult technical manuals, operating procedures, or other relevant documents for guidance.

- Seek guidance from colleagues: I would ask experienced colleagues for advice or assistance.

- Contact supervisor: If necessary, I would escalate the issue to my supervisor for support or clarification.

- Research: I would independently research available resources to find solutions to the problem.

8. How do you stay up-to-date with the latest industry best practices and technological advancements in plate filling?

To stay up-to-date with the latest industry best practices and technological advancements in plate filling, I would:

- Attend training and workshops: I would participate in industry-organized training programs and workshops to enhance my skills and knowledge.

- Read industry publications: I would subscribe to relevant trade magazines and journals to stay informed about new techniques and technologies.

- Network with professionals: I would attend industry events and conferences to connect with other professionals and exchange ideas.

- Research and explore: I would actively seek out and explore new technologies and methodologies through online resources and research.

9. How do you handle working in a team environment and collaborating with others?

In a team environment, I believe in effective collaboration and teamwork:

- Communication: I would actively participate in team meetings and discussions, ensuring clear and open communication.

- Cooperation: I would work cooperatively with colleagues, sharing knowledge and supporting each other to achieve common goals.

- Respect: I would treat all team members with respect, valuing their perspectives and contributions.

- Problem-solving: I would actively participate in problem-solving sessions, contributing ideas and working towards collective solutions.

10. How do you see yourself contributing to our team as a Manual Plate Filler?

As a Manual Plate Filler, I am confident that I can make valuable contributions to your team:

- Expertise and experience: My experience and technical skills in plate filling would enable me to perform my duties efficiently and effectively.

- Attention to detail: My meticulous nature and attention to detail would ensure that I consistently meet or exceed quality standards.

- Problem-solving abilities: My analytical and problem-solving abilities would allow me to quickly identify and resolve any issues during the plate filling process.

- Teamwork and collaboration: My strong teamwork and collaboration skills would enable me to work effectively with other team members to achieve shared goals.

- Continuous improvement: I am committed to continuous improvement and would actively seek opportunities to enhance my knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manual Plate Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manual Plate Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manual Plate Fillers play an essential role in the food production industry by filling and sealing plates with various food products. Their key responsibilities include:

1. Plate Filling

The primary task involves manually filling empty plates with pre-portioned food items, ensuring the correct quantity and presentation according to specified recipes or customer orders.

- Accurately dispense measured amounts of food onto plates using scoops, spoons, or other utensils.

- Arrange food items aesthetically on plates, paying attention to presentation and portion control.

- Garnish plates with additional ingredients to enhance visual appeal, such as herbs, sauces, or garnishes.

2. Plate Sealing

Once the plates are filled, Manual Plate Fillers are responsible for sealing them with a variety of materials to preserve freshness and prevent contamination.

- Apply plastic wrap or foil to plates, ensuring a tight seal to maintain food quality and prevent spillage.

- Use heat-sealing machines to seal plates with airtight film, extending the shelf life of food products.

- Adhere labels or tags to sealed plates to provide product information, expiration dates, and any necessary handling instructions.

3. Quality Control

Manual Plate Fillers are responsible for maintaining high standards of food safety and quality.

- Inspect plates for any blemishes, contamination, or foreign objects to ensure food safety.

- Monitor food temperatures and storage conditions to adhere to food safety regulations.

- Follow proper hygiene practices, including wearing gloves and washing hands regularly, to prevent cross-contamination.

4. Equipment Maintenance

Manual Plate Fillers are expected to maintain basic equipment used in their daily tasks.

- Clean and sanitize work surfaces, utensils, and equipment to prevent contamination.

- Report any equipment malfunctions or issues to supervisors promptly.

- Adhere to safety protocols while operating equipment, ensuring a safe work environment.

Interview Tips

To ace the interview for a Manual Plate Filler position, here are some valuable tips:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the position and help you answer questions intelligently.

- Visit the company’s website to gather information about their mission, values, and industry standing.

- Read online reviews and articles to gain insights into the company culture and work environment.

- Thoroughly review the job description to understand the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

During the interview, focus on showcasing your relevant skills and experience that align with the requirements of the Manual Plate Filler role.

- Emphasize your attention to detail and ability to follow instructions accurately.

- Provide examples of your experience in food handling, portion control, and maintaining food safety.

- Discuss your ability to work in a fast-paced environment and handle multiple tasks efficiently.

3. Demonstrated Physical Abilities

Interviewers will be interested in assessing your physical abilities, as the role involves standing for extended periods and performing repetitive tasks.

- Highlight your ability to maintain good posture and work on your feet for prolonged periods.

- Emphasize your manual dexterity and coordination in handling food items and equipment.

- If possible, provide examples of physically demanding work you have done previously.

4. Positive Attitude and Eagerness to Learn

Interviewers will be looking for candidates with a positive attitude and a willingness to learn new tasks. Demonstrating these qualities can significantly improve your chances of success.

- Express your enthusiasm for working in the food industry and your passion for food safety.

- Show your willingness to follow instructions and learn from experienced colleagues.

- Ask questions about the company, the role, and opportunities for professional development.

5. Professional Appearance and Punctuality

First impressions matter, so it is crucial to dress professionally and arrive for the interview on time. This demonstrates respect for the interviewer and their time.

- Choose clothing that is clean, pressed, and appropriate for a food production environment.

- Be punctual for the interview and inform the interviewer if you anticipate any delays.

- Maintain good posture and make eye contact during the interview to project confidence and professionalism.

Next Step:

Now that you’re armed with the knowledge of Manual Plate Filler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Manual Plate Filler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini