Are you gearing up for a career in Metal Fabricating Shop Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Fabricating Shop Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

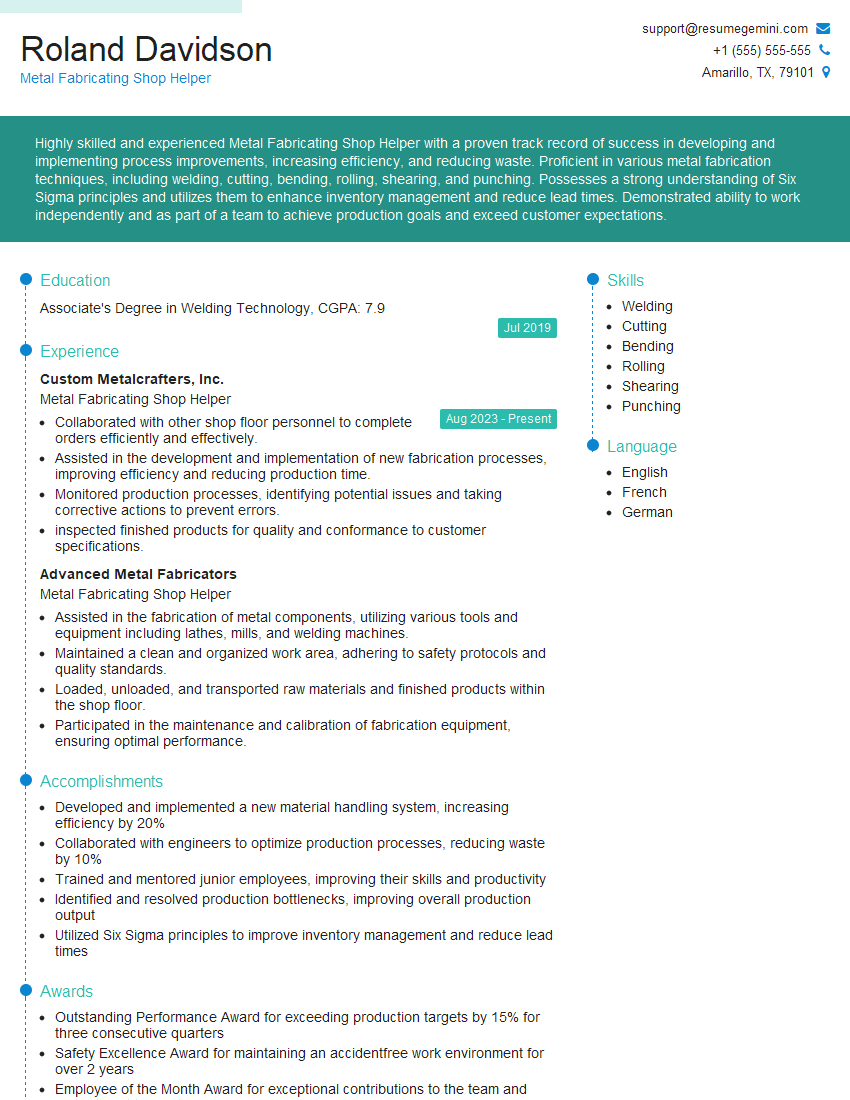

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Fabricating Shop Helper

1. What are the different types of metal fabrication processes?

There are several different types of metal fabrication processes, including:

- Cutting: This process involves cutting metal into the desired shape and size using tools such as shears, saws, and lasers.

- Forming: This process involves bending or shaping metal into the desired shape using tools such as presses, brakes, and rolls.

- Welding: This process involves joining metal pieces together using heat and filler material.

- Machining: This process involves removing material from metal using tools such as lathes, mills, and drills.

- Finishing: This process involves cleaning and protecting the metal surface using methods such as sandblasting, painting, and plating.

2. What are the common materials used in metal fabrication?

- Steel: This is a strong and durable material that is often used in structural applications.

- Aluminum: This is a lightweight and corrosion-resistant material that is often used in automotive and aerospace applications.

- Stainless steel: This is a corrosion-resistant material that is often used in food processing and medical applications.

- Copper: This is a conductive material that is often used in electrical applications.

- Brass: This is a corrosion-resistant material that is often used in plumbing and marine applications.

3. What are the safety hazards associated with metal fabrication?

- Cuts and lacerations: These can occur from contact with sharp edges or tools.

- Burns: These can occur from contact with hot metal or flames.

- Eye injuries: These can occur from flying sparks or chips.

- Respiratory hazards: These can occur from exposure to welding fumes or other airborne contaminants.

- Hearing loss: This can occur from exposure to loud noises.

4. What are the different types of welding processes?

- Arc welding: This process uses an electric arc to melt the metal and join it together.

- MIG welding (metal inert gas welding): This process uses a shielding gas to protect the weld from contamination.

- TIG welding (tungsten inert gas welding): This process uses a tungsten electrode to create a focused arc.

- Stick welding: This process uses a consumable electrode that melts and joins the metal together.

- Oxy-fuel welding: This process uses a combination of oxygen and fuel gas to create a flame that melts the metal and joins it together.

5. What are the different types of cutting processes?

- Shearing: This process uses a sharp blade to cut metal into the desired shape.

- Sawing: This process uses a saw blade to cut metal into the desired shape.

- Laser cutting: This process uses a laser to cut metal into the desired shape.

- Water jet cutting: This process uses a high-pressure stream of water to cut metal into the desired shape.

- Plasma cutting: This process uses a plasma torch to cut metal into the desired shape.

6. What are the different types of forming processes?

- Bending: This process involves bending metal into the desired shape using a press or brake.

- Rolling: This process involves passing metal through a series of rollers to reduce its thickness or change its shape.

- Stamping: This process involves using a die to press a design into metal.

- Drawing: This process involves pulling metal through a die to create a desired shape.

- Extrusion: This process involves forcing metal through a die to create a desired shape.

7. What are the different types of finishing processes?

- Sandblasting: This process uses a stream of abrasive material to clean and smooth metal surfaces.

- Painting: This process involves applying a coating of paint to metal surfaces to protect them from corrosion and wear.

- Plating: This process involves applying a thin layer of metal to the surface of another metal to improve its properties.

- Anodizing: This process involves creating a protective oxide layer on the surface of aluminum.

8. What is the purpose of a bill of materials (BOM)?

A BOM is a document that lists all of the materials required to manufacture a product. It includes information such as the quantity of each material, the material’s description, and the material’s specifications.

9. What is the difference between a blueprint and a schematic?

A blueprint is a detailed drawing that shows the physical dimensions of a product. A schematic is a diagram that shows the electrical or mechanical connections between different components of a product.

10. What is the role of a metal fabricating shop helper?

- Assist metal fabricators with various tasks, such as cutting, forming, welding, and finishing metal.

- Clean and maintain the metal fabrication shop and equipment.

- Inspect finished products to ensure that they meet specifications.

- Help to load and unload materials and products.

- Perform other tasks as assigned.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Fabricating Shop Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Fabricating Shop Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Fabricating Shop Helper is responsible for providing essential support in a metal fabrication environment. Their duties involve assisting with various tasks, ensuring the smooth operation of the shop and the production of high-quality metal products.

1. Assisting with Fabrication Processes

The helper assists with a range of fabrication processes, including cutting, bending, welding, and assembly. They may operate machinery, prepare materials, and provide general support to fabricators.

- Assisting in the setup, operation, and maintenance of fabrication equipment

- Preparing and handling metal materials, including cutting, bending, and shaping

2. Maintaining Shop Environment

Helpers are responsible for maintaining a clean and organized work area. They keep tools and equipment in good condition, dispose of waste materials, and ensure the shop meets safety regulations.

- Cleaning and organizing the shop floor, including sweeping and mopping

- Maintaining and inspecting tools and equipment, ensuring they are in working order

3. Quality Control and Inspection

Helpers assist with quality control by visually inspecting finished products, identifying defects, and reporting any issues. They may also be involved in testing and measuring to ensure products meet specifications.

- Visually inspecting fabricated parts for defects, such as scratches, dents, and misalignments

- Measuring and testing parts to ensure they meet specifications and tolerances

4. Material Handling and Inventory

Helpers are responsible for handling and transporting materials within the shop. They may also assist with inventory management, ensuring that materials and supplies are available for production.

- Loading and unloading materials from trucks and storage areas

- Maintaining inventory levels and assisting with ordering and receiving materials

Interview Preparation Tips

To prepare for an interview for a Metal Fabricating Shop Helper position, there are several steps you can take to increase your chances of success:

1. Research the Company and Position

Familiarize yourself with the company’s website, industry, and products. Research the specific job description and identify the key responsibilities and qualifications required for the role.

- Visit the company’s website to learn about their products, services, and culture.

- Read the job description carefully and highlight the key skills and experience the employer is looking for.

2. Practice Answering Interview Questions

Prepare answers to common interview questions, such as those related to your experience, skills, and why you are interested in the role. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Consider questions about your experience with metal fabrication, quality control, and safety procedures.

- Practice describing your problem-solving skills and ability to work in a fast-paced environment.

3. Highlight Your Relevant Skills and Experience

Emphasize your relevant skills and experience in your resume and cover letter. Quantify your accomplishments whenever possible using specific numbers or metrics. If you have previous experience in metal fabrication or a related field, be sure to highlight it.

- Quantify your experience whenever possible, such as “Assisted in the production of over 1000 metal components per month.”

- Use action verbs to describe your responsibilities, such as “operated,” “maintained,” and “inspected.”

4. Demonstrate Your Safety Awareness

Metal fabrication involves working with dangerous equipment and materials, so it is crucial to demonstrate your understanding of safety procedures. In your interview, discuss your knowledge of safety regulations and your commitment to following them.

- Describe your knowledge of OSHA regulations and industry best practices.

- Explain your commitment to wearing personal protective equipment (PPE) and following safety protocols.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Fabricating Shop Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.