Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Parter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

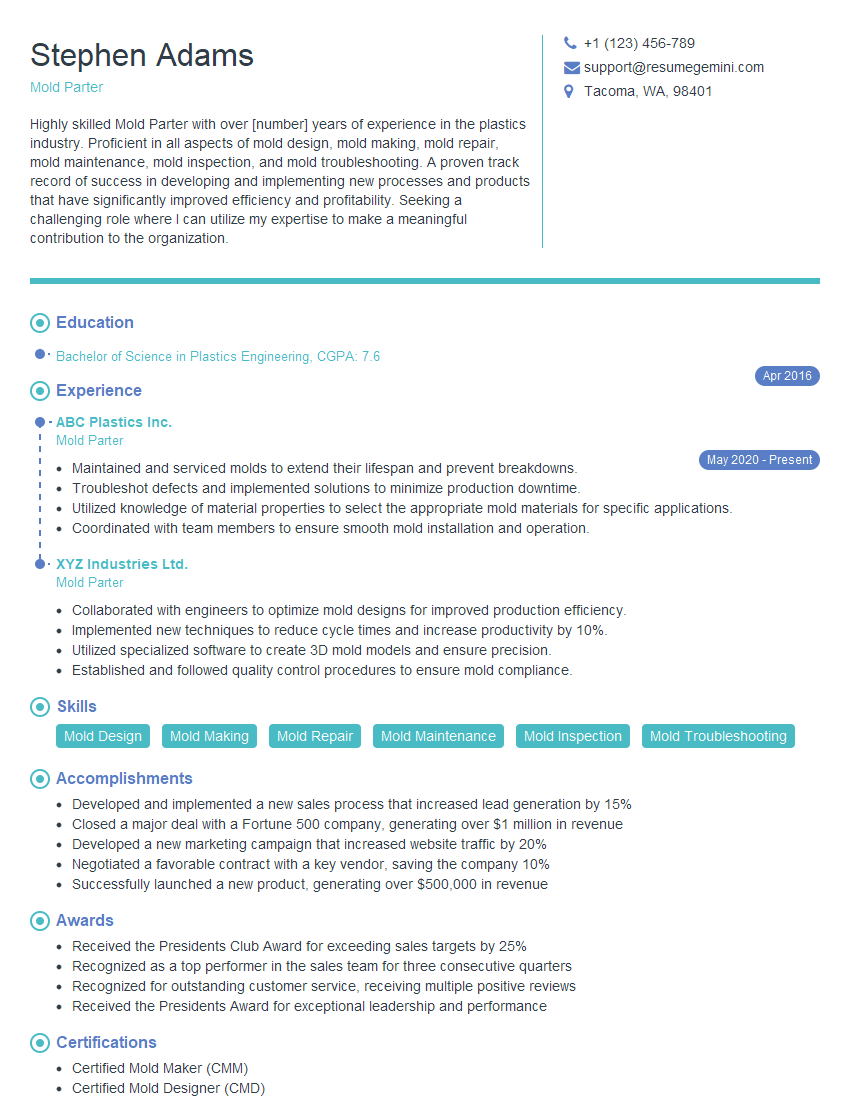

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Parter

1. Explain the process of making a mold from scratch.

- Start by creating a model of the part you want to mold.

- Make a mold box around the model.

- Pour a liquid molding material into the mold box.

- Allow the molding material to harden.

- Remove the mold box and the model from the mold.

- The mold is now ready to be used to produce parts.

2. What are the different types of molding materials and their applications?

Metal Casting

- Sand casting

- Investment casting

- Die casting

Plastic Molding

- Injection molding

- Blow molding

- Rotational molding

Composite Molding

- Hand lay-up

- Spray-up

- RTM (Resin Transfer Molding)

3. What are the factors to consider when choosing a molding process?

- The type of material to be molded

- The quantity of parts to be produced

- The accuracy and complexity of the parts

- The cost of the molding process

- The availability of equipment and tooling

4. What are the common defects that can occur in mold making and how can they be prevented?

- Flash– Material that leaks out of the mold during the molding process.

- Voids– Air bubbles that are trapped in the mold.

- Sink marks– Depressions in the part caused by shrinkage of the material during cooling.

- Cracks– Breaks in the mold or the part.

These defects can be prevented by:

- Using the correct molding process and materials

- Properly designing the mold

- Controlling the molding conditions

- Inspecting the parts regularly

5. How do you maintain and repair molds?

- Cleaning– Molds should be cleaned regularly to remove any dirt or debris.

- Inspection– Molds should be inspected regularly for any signs of wear or damage.

- Repair– Any damage to the mold should be repaired promptly.

- Storage– Molds should be stored in a dry, clean place when not in use.

6. What are the safety precautions that should be taken when working with molds?

- Wear appropriate safety gear, including gloves, safety glasses, and a respirator.

- Handle molds with care.

- Be aware of the hazards associated with the molding materials being used.

- Follow all safety instructions provided by the manufacturer of the molding equipment.

- Never work alone when operating molding equipment.

7. What are the latest trends in mold making?

- Additive manufacturing– 3D printing technology is being used to create molds.

- Rapid tooling– New techniques are being developed to create molds quickly and inexpensively.

- Sustainable molding– New materials and processes are being developed to reduce the environmental impact of mold making.

- Automation– Molding equipment is becoming more automated, which is reducing the need for manual labor.

8. How do you stay up to date on the latest trends in mold making?

- Read industry publications.

- Attend trade shows and conferences.

- Network with other mold makers.

- Take online courses.

9. What are your strengths and weaknesses as a mold maker?

10. Why are you interested in this position?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Parter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Parter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Parters are responsible for the safe and efficient operation of mold making machines, ensuring the production of high-quality molds for various industries. Their key responsibilities include:

1. Molding and Pressing Operations

Operating mold making machines to create molds according to specifications, using appropriate materials and techniques

- Setting up and operating molding machines

- Selecting and installing appropriate molds

- Monitoring molding and pressing processes

2. Quality Control and Inspection

Inspecting molds to ensure they meet specifications and quality standards

- Conducting visual inspections

- Using measuring instruments to verify dimensions

- Identifying and resolving any defects

3. Machine Maintenance and Troubleshooting

Maintaining and troubleshooting mold making machines to ensure optimal performance

- Performing routine maintenance tasks

- Diagnosing and resolving machine issues

- Collaborating with maintenance technicians for major repairs

4. Production Monitoring and Reporting

Monitoring production processes, tracking mold usage, and reporting production data

- Collecting and analyzing production data

- Identifying areas for improvement

- Communicating production status to supervisors

Interview Tips

Preparing for an interview for a Mold Parter role requires a combination of technical knowledge, problem-solving abilities, and communication skills. Here are some key tips to help you ace the interview:

1. Highlight Your Molding Expertise

Emphasize your experience and skills in mold making, including the types of molds you have worked with, the materials used, and the equipment you are proficient in operating

- Quantify your accomplishments, such as the number of molds produced or the reduction in defect rates

- Use specific examples to demonstrate your understanding of mold design, material properties, and molding techniques

2. Showcase Your Problem-Solving Abilities

Mold Parting often involves troubleshooting and problem-solving during production. Describe situations where you successfully diagnosed and resolved issues with mold making machines or identified and corrected defects in molds

- Explain your approach to problem-solving, including the steps you take to identify the root cause and implement solutions

- Share examples of how you have improved efficiency or resolved quality issues through innovative solutions

3. Communicate Effectively

Mold Parters need to be able to communicate effectively with supervisors, colleagues, and customers. Highlight your communication skills, both verbal and written

- Demonstrate your ability to clearly convey technical information and discuss molding processes

- Provide examples of how you have successfully communicated with stakeholders, resolved conflicts, or provided technical assistance

4. Research the Company and Industry

Research the company and the mold-making industry to demonstrate your interest and understanding of the role. Show that you are aware of the company’s products, services, and industry trends

- Review the company’s website and LinkedIn profile

- Read industry publications and attend industry events

- Prepare questions that demonstrate your engagement and enthusiasm for the role

Next Step:

Now that you’re armed with the knowledge of Mold Parter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mold Parter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini