Are you gearing up for an interview for a Multiple Drum Sander Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Multiple Drum Sander Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

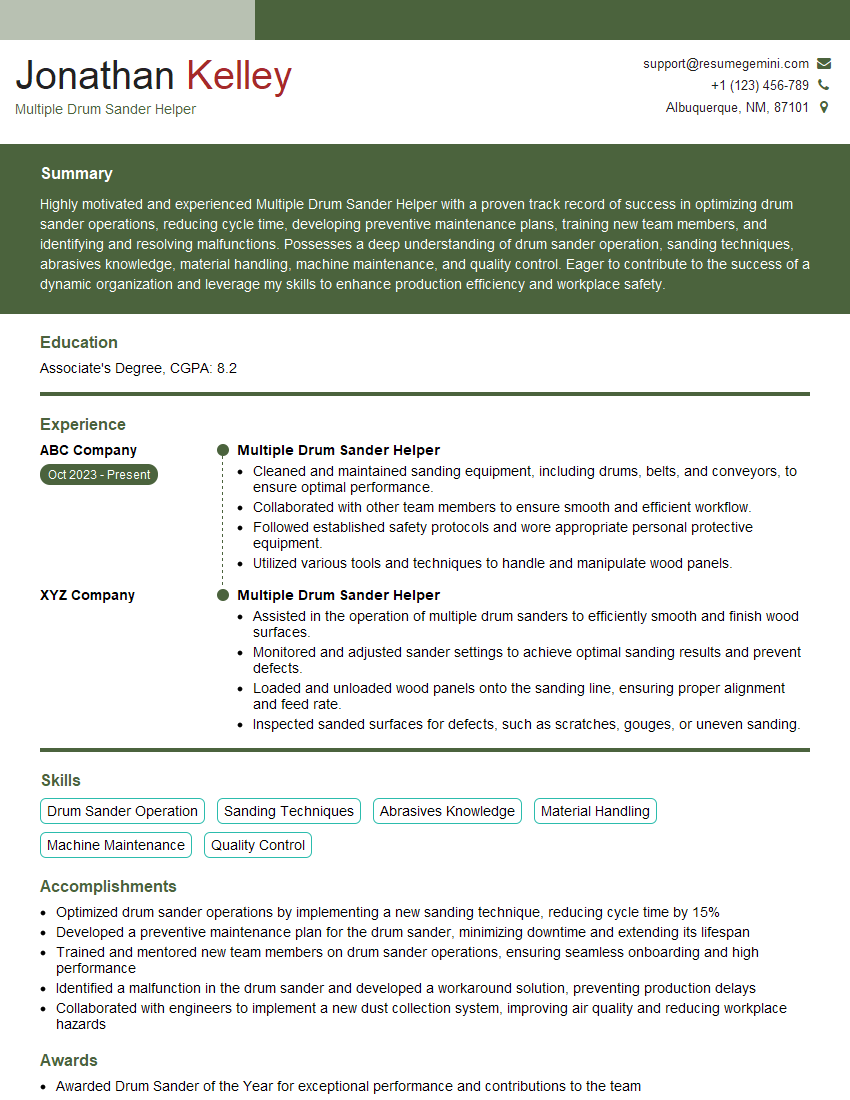

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Multiple Drum Sander Helper

1. Explain the process of sanding using a multiple drum sander?

The process of sanding using a multiple drum sander involves several steps:

- Loading the workpiece: The workpiece is securely loaded onto the conveyor belt, ensuring it is aligned correctly for sanding.

- Setting the sanding parameters: The appropriate sanding speed, feed rate, and drum pressure are set based on the workpiece material and desired finish.

- Sanding: The workpiece moves through the sander, passing over multiple rotating drums equipped with abrasive belts. Each drum performs a specific sanding operation, such as rough sanding, intermediate sanding, or fine sanding.

- Unloading the workpiece: Once sanded, the workpiece is removed from the conveyor belt and inspected for quality and accuracy.

2. How do you determine the correct grit size and spacing for sanding different materials?

Selecting the appropriate grit size and spacing for different materials is crucial for achieving the desired sanding results. Here’s how I approach it:

Grit Size

- Coarse grit (40-80): Used for removing heavy material, shaping, and leveling.

- Medium grit (100-150): Used for smoothing surfaces and removing scratches from previous sanding.

- Fine grit (180-220): Used for final sanding to achieve a smooth and refined finish.

Spacing

- Open spacing: Allows for aggressive sanding and efficient material removal, but may leave visible scratches.

- Closed spacing: Provides a finer finish with fewer scratches but may require more passes.

3. What are the common defects that can occur during multiple drum sanding and how do you address them?

Multiple drum sanding can result in various defects if not performed correctly. Here’s how I identify and address them:

- Burn marks: Caused by excessive heat buildup. I adjust the feed rate, reduce sanding pressure, or use a coarser grit to prevent burning.

- Uneven sanding: Occurs when the workpiece is not aligned properly or the drums are not balanced. I recalibrate the machine, ensure proper workpiece alignment, and check drum balance.

- Scratches: Caused by using too coarse a grit or incorrect spacing. I switch to a finer grit and adjust the spacing to minimize scratches.

- Delamination: Occurs when the adhesive holding the layers of the workpiece fails. I lower the sanding pressure, use a finer grit, and apply proper adhesive to prevent delamination.

4. How do you maintain and calibrate a multiple drum sander to ensure optimal performance?

Regular maintenance and calibration are essential for optimal performance of a multiple drum sander. I follow these key steps:

- Lubrication: I lubricate all moving parts, such as bearings and drive mechanisms, to prevent wear and ensure smooth operation.

- Drum alignment: I check and adjust the alignment of the sanding drums to ensure they are parallel to each other and perpendicular to the workpiece feed.

- Abrasive belt tension: I inspect and adjust the tension of the abrasive belts to prevent slipping or breakage.

- Conveyor belt tracking: I align and adjust the conveyor belt to ensure the workpiece moves smoothly and consistently through the sander.

5. What safety precautions should be taken when operating a multiple drum sander?

Operating a multiple drum sander requires strict adherence to safety precautions to prevent accidents and injuries:

- PPE: Wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, dust mask, and gloves.

- Machine guarding: Ensure all machine guards are in place and functioning properly to prevent contact with moving parts.

- Emergency stop: Be familiar with the location and proper use of the emergency stop button in case of an emergency.

- Lockout/tagout: Follow lockout/tagout procedures before performing maintenance or repairs to prevent accidental startup.

6. Explain the importance of proper dust collection when using a multiple drum sander?

Proper dust collection is crucial when using a multiple drum sander for several reasons:

- Health hazards: Wood dust is harmful to inhale and can cause respiratory issues. Dust collection removes dust from the air, protecting the operator and others.

- Workpiece quality: Dust accumulation on the workpiece can interfere with sanding and lead to defects. Dust collection helps maintain a clean sanding environment.

- Machine maintenance: Dust buildup inside the sander can damage components and reduce performance. Dust collection helps keep the machine clean and extends its lifespan.

7. Describe the different types of abrasive belts used in multiple drum sanding and their applications?

There are various types of abrasive belts used in multiple drum sanding, each serving specific applications:

- Aluminum oxide: General-purpose abrasive suitable for sanding a wide range of materials, including wood, metal, and composites.

- Zirconium oxide: Durable and long-lasting abrasive used for heavy-duty sanding and stock removal.

- Ceramic: Premium abrasive that provides a sharp cut and extended life, ideal for precision sanding and fine finishing.

- Sandpaper: Traditional abrasive made from natural materials, commonly used for light sanding and finishing.

8. How do you troubleshoot common problems that may arise during multiple drum sanding?

Troubleshooting common problems during multiple drum sanding requires a systematic approach:

- Burn marks: Check feed rate, sanding pressure, and grit size. Adjust as necessary to reduce heat buildup.

- Uneven sanding: Inspect workpiece alignment, drum balance, and conveyor belt tracking. Make necessary adjustments.

- Poor surface finish: Assess grit size, spacing, and abrasive belt condition. Adjust settings or replace belts as needed.

- Machine vibrations: Check drum alignment, belt tension, and overall machine stability. Adjust or repair as required.

9. Explain how you would set up and operate a multiple drum sander to achieve a specific surface finish?

To achieve a specific surface finish using a multiple drum sander involves careful setup and operation:

- Grit selection: Choose the appropriate grit size based on the desired finish and material.

- Spacing adjustment: Set the belt spacing to achieve the desired level of smoothness or aggression.

- Feed rate: Adjust the feed rate to control the amount of material removed per pass.

- Sanding pressure: Calibrate the sanding pressure to balance material removal with surface quality.

10. Describe the importance of regular maintenance and cleaning of a multiple drum sander?

Regular maintenance and cleaning of a multiple drum sander are essential for optimal performance and longevity:

- Dust collection: Clean dust collectors regularly to maintain airflow and prevent clogging.

- Abrasive belt replacement: Inspect and replace abrasive belts as needed to ensure sharpness and prevent uneven sanding.

- Drum cleaning: Clean sanding drums to remove any buildup or residue that could affect the sanding process.

- Lubrication: Lubricate all moving parts to minimize friction and wear.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Multiple Drum Sander Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Multiple Drum Sander Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Multiple Drum Sander Helpers are responsible for assisting in the operation and maintenance of multiple drum sanders in a manufacturing setting. Their primary duties include:

1. Machine Operation

Assist in setting up, calibrating, and operating multiple drum sander machines according to specified parameters.

- Load and unload materials onto the sander conveyor system.

- Monitor machine operations and make adjustments as needed to ensure optimal sanding results.

2. Quality Control

Inspect sanded materials for defects, such as uneven sanding, scratches, or burn marks.

- Conduct quality checks on sanded materials to meet production standards.

- Report any defects or quality issues to the supervisor.

3. Machine Maintenance

Assist in maintaining and cleaning multiple drum sanders to ensure proper functioning.

- Clean and lubricate machine components regularly.

- Replace worn or damaged parts as needed.

4. Safety Compliance

Follow all safety protocols and procedures while working with multiple drum sanders.

- Wear appropriate personal protective equipment (PPE), such as earplugs, safety glasses, and gloves.

- Report any safety hazards or accidents to the supervisor immediately.

Interview Tips

Preparing for an interview for a Multiple Drum Sander Helper position can help you showcase your skills and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Multiple Drum Sander Helper position you are applying for. This will help you understand the company’s culture, values, and the job requirements. Demonstrating your knowledge of the company shows that you are invested in the opportunity.

- Visit the company website to learn about their products, services, and mission statement.

- Review the job description carefully to identify the key skills and experience required for the role.

2. Highlight Your Skills and Experience

During the interview, be prepared to highlight your skills and experience that are relevant to the Multiple Drum Sander Helper position. Focus on your ability to operate and maintain multiple drum sanders, ensure quality control, and comply with safety regulations. Provide specific examples of your work experience to demonstrate your capabilities.

- Describe your experience in setting up, calibrating, and operating multiple drum sanders.

- Share examples of how you have ensured quality control standards in a manufacturing setting.

- Explain your knowledge of safety protocols for working with multiple drum sanders.

3. Emphasize Your Teamwork and Communication

Multiple Drum Sander Helpers often work as part of a team in a manufacturing environment. Emphasize your teamwork skills and ability to communicate effectively with colleagues and supervisors. Highlight your experience in collaborating with others to achieve production goals and resolve issues.

- Describe a time when you worked effectively as part of a team to solve a problem or meet a deadline.

- Explain how you communicate clearly and respectfully with colleagues and supervisors.

4. Prepare for Common Interview Questions

In addition to highlighting your skills and experience, be prepared to answer common interview questions. These may include questions about your motivation for applying for the position, your career goals, and your strengths and weaknesses. Practice answering these questions concisely and professionally.

- Why are you interested in this Multiple Drum Sander Helper position?

- What are your career goals for the next 5 years?

- What are your strengths and weaknesses as they relate to this role?

5. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions to the interviewer. This shows that you are engaged and interested in the position. Ask about the company’s culture, the training opportunities available, or the company’s future plans. Asking informed questions can leave a lasting impression and demonstrate your interest in the role.

- What is the company’s culture like?

- What training opportunities are available to employees?

- What are the company’s future plans for growth or expansion?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Multiple Drum Sander Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!