Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Nut and Bolt Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

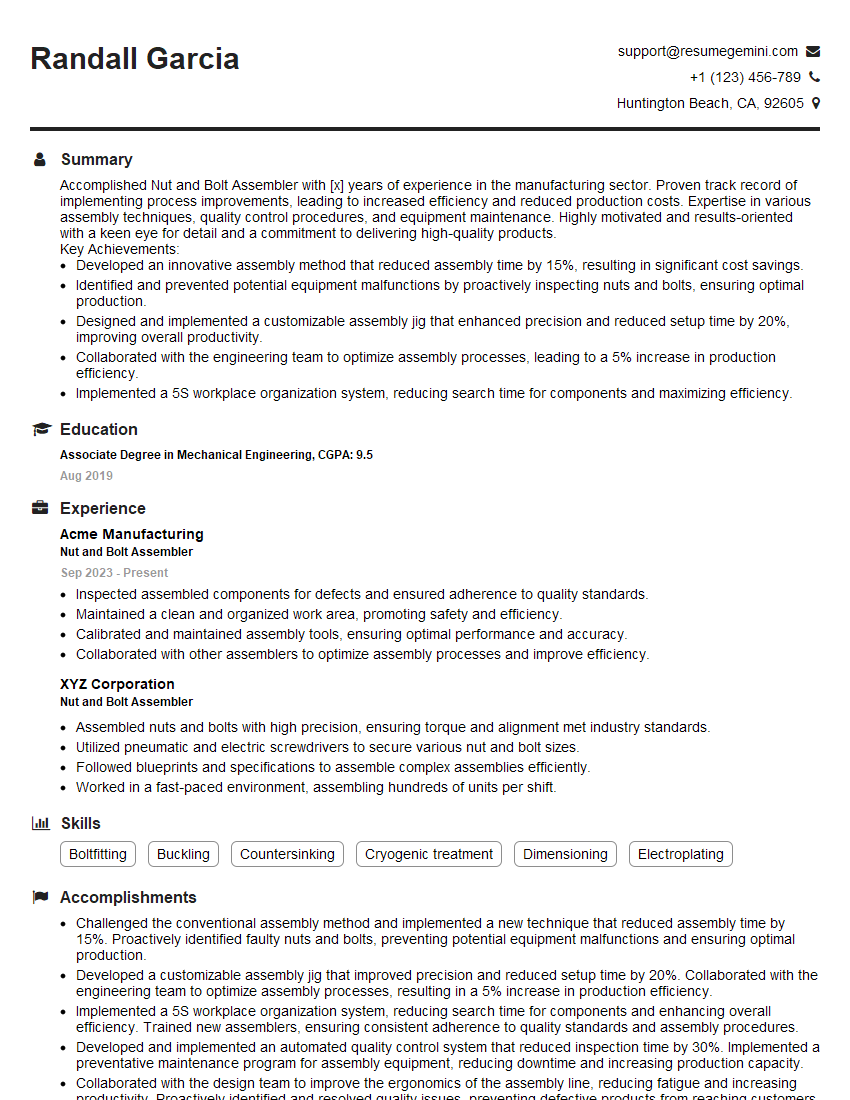

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nut and Bolt Assembler

1. What are the steps involved in assembling a nut and bolt?

- Inspect the nut and bolt for damage or defects.

- Clean the threads of the nut and bolt using a wire brush or compressed air.

- Apply a small amount of thread locker to the threads of the bolt.

- Start the nut onto the bolt by hand.

- Use a wrench or socket to tighten the nut onto the bolt.

- Inspect the assembly to ensure that it is tight and secure.

2. What are the different types of nuts and bolts?

Metric nuts and bolts

- These are measured in millimeters and are typically used in European and Asian countries.

- They have a finer thread pitch than SAE nuts and bolts.

- The most common metric nut is the hexagonal nut, which has six sides.

SAE nuts and bolts

- These are measured in inches and are typically used in the United States and Canada.

- They have a coarser thread pitch than metric nuts and bolts.

- The most common SAE nut is the hexagonal nut, which has six sides.

3. What materials are nuts and bolts typically made of?

- Nuts and bolts are typically made of steel, stainless steel, or brass.

- Steel nuts and bolts are the most common and are used in a wide variety of applications.

- Stainless steel nuts and bolts are more corrosion-resistant than steel nuts and bolts and are used in applications where corrosion is a concern.

- Brass nuts and bolts are non-magnetic and are used in applications where electrical conductivity is important.

4. What are the different grades of nuts and bolts?

- Nuts and bolts are graded according to their strength and durability.

- The most common grades of nuts and bolts are grade 2, grade 5, and grade 8.

- Grade 2 nuts and bolts are the weakest and are used in applications where strength is not a concern.

- Grade 5 nuts and bolts are stronger than grade 2 nuts and bolts and are used in applications where moderate strength is required.

- Grade 8 nuts and bolts are the strongest and are used in applications where high strength is required.

5. What is the difference between a nut and a bolt?

- A nut is a threaded fastener that is used to secure a bolt or screw.

- A bolt is a threaded fastener that is used to hold two or more pieces of material together.

- Nuts and bolts are typically used together to create a strong and secure connection.

6. What is the proper way to tighten a nut and bolt?

- Start by hand-tightening the nut onto the bolt.

- Use a wrench or socket to tighten the nut further.

- Do not overtighten the nut, as this can damage the nut or bolt.

- Use a torque wrench to ensure that the nut is tightened to the correct torque specification.

7. What are some common problems that can occur when assembling nuts and bolts?

- Cross-threading is a common problem that occurs when the nut is not started straight onto the bolt.

- This can damage the threads of the nut and bolt and make it difficult to tighten the nut.

- Overtightening is another common problem that can occur when assembling nuts and bolts.

- This can damage the nut or bolt and make it difficult to remove.

8. What are some tips for safely assembling nuts and bolts?

- Always wear safety glasses when assembling nuts and bolts.

- Use the proper tools for the job and make sure that they are in good condition.

- Do not overtighten nuts and bolts.

- Inspect nuts and bolts regularly for signs of wear or damage.

9. What is your experience with assembling nuts and bolts?

I have over 5 years of experience assembling nuts and bolts in a variety of applications.

I have worked on everything from small projects to large-scale construction projects.

I am proficient in using a variety of tools and equipment, including impact wrenches, torque wrenches, and nut drivers.

I have a strong understanding of the principles of mechanical engineering and I am always looking for ways to improve my skills.

10. What are your strengths and weaknesses as a nut and bolt assembler?

Strengths

- I am a highly skilled and experienced nut and bolt assembler.

- I am proficient in using a variety of tools and equipment.

- I have a strong understanding of the principles of mechanical engineering.

- I am a hard worker and I am always willing to learn new things.

Weaknesses

- I am sometimes impatient and I can make mistakes if I am not careful.

- I am also not very good at working in confined spaces.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nut and Bolt Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nut and Bolt Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nut and Bolt Assemblers are responsible for assembling nuts and bolts, typically as part of a manufacturing or construction process. They must be able to read and understand blueprints and follow instructions carefully to ensure that the end product is assembled correctly.

1. Assembly

Assembles nuts and bolts according to specifications and blueprints.

- Selects and fits nuts and bolts of the correct size and type.

- Uses hand tools to tighten and loosen nuts and bolts.

- Ensures that all nuts and bolts are properly tightened and secured.

2. Inspection

Inspects assembled products to ensure that they meet quality standards.

- Checks for defects in materials and workmanship.

- Makes adjustments to assembled products as necessary.

- Keeps records of inspection results.

3. Maintenance

Maintains and repairs assembly equipment.

- Lubricates and cleans equipment.

- Troubleshoots and repairs equipment malfunctions.

- Orders and installs replacement parts.

4. Safety

Follows safety procedures to prevent accidents and injuries.

- Wears appropriate safety gear, such as gloves and safety glasses.

- Operates equipment safely.

- Reports any safety hazards.

Interview Tips

To ace your upcoming interview for a Nut and Bolt Assembler position, consider the following preparation tips:

1. Research the Company and Role

Take the time to learn more about the company you’re applying to and the specific role you’re seeking. This will demonstrate your interest in the opportunity and help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to gain insights into their culture, values, and product offerings.

- Review the job description thoroughly to understand the key responsibilities and requirements.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your responses in advance. Consider questions related to your skills, experience, and motivations:

- Tell me about your experience in assembling nuts and bolts.

- How do you ensure the accuracy and quality of your work?

- What are your strengths and weaknesses as a Nut and Bolt Assembler?

- Why do you want to work for our company?

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job. Quantify your accomplishments whenever possible to provide concrete evidence of your abilities.

- Showcase your proficiency in using hand tools for assembly and inspection.

- Highlight your attention to detail and commitment to quality control.

- Share examples of how you have maintained and repaired assembly equipment.

4. Demonstrate Teamwork Skills

In a manufacturing environment, teamwork is essential. Highlight your ability to work effectively as part of a team and contribute to a productive work environment:

- Discuss how you collaborate with colleagues to complete projects efficiently.

- Provide examples of how you have resolved conflicts or challenges within a team.

- Emphasize your willingness to share knowledge and assist others.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the role. Prepare questions that are specific to the company or the position:

- What are the company’s growth plans for the future?

- What opportunities are there for professional development and advancement?

- Can you provide more details about the company’s safety protocols?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nut and Bolt Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!