Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Nut Process Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

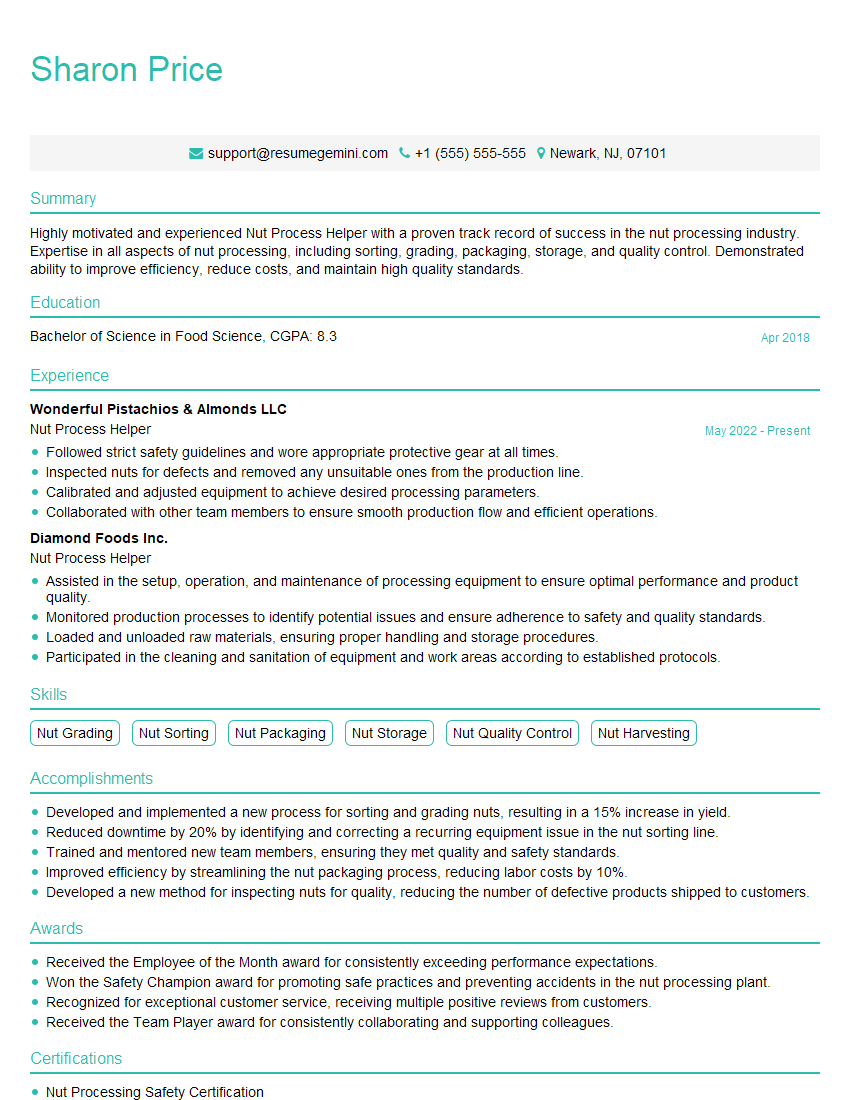

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nut Process Helper

1. Describe the process of nut sorting and grading?

The process of nut sorting and grading involves several key steps:

- Size grading: Nuts are separated into different sizes using screens or graders based on their physical dimensions.

- Color grading: Nuts are sorted based on their color, shape, and appearance to separate discolored or damaged nuts from high-quality ones.

- Density grading: Nuts are separated based on their density using air classifiers or flotation tanks. This process removes lighter or heavier nuts from the batch.

- Moisture grading: Nuts are tested for moisture content to ensure they meet specific standards and prevent spoilage or rancidity.

- Foreign material removal: Nuts are inspected and cleaned to remove any foreign materials, such as stones, dirt, or debris.

2. What are the different types of nuts you have worked with before?

I have experience working with a wide variety of nuts, including:

- Almonds

- Cashews

- Hazelnuts

- Macadamia nuts

- Pecans

- Pistachios

- Walnuts

3. What is the importance of proper storage and handling of nuts?

Proper storage and handling of nuts is crucial to maintain their quality and prevent spoilage:

- Storage temperature: Nuts should be stored in a cool, dry place to prevent rancidity and extend their shelf life.

- Humidity control: Nuts should be stored in a controlled humidity environment to prevent moisture absorption or loss.

- Pest control: Storage facilities should be regularly inspected and treated to prevent infestation by pests or rodents.

- Packaging: Nuts should be packaged in airtight containers or bags to protect them from moisture and oxygen.

- Handling: Nuts should be handled carefully to avoid damage or bruising, which can compromise their quality.

4. Describe the methods used to crack and shell nuts?

The methods used to crack and shell nuts vary depending on the type of nut:

- Mechanical cracking: Nuts are placed in a mechanical cracker that applies pressure to break the shell.

- Hand cracking: Nuts are cracked manually using a nutcracker or hammer.

- Shelling machines: Nuts are placed in a machine that uses rotating drums or blades to remove the shell.

- Water jet shelling: Water jets are used to cut and remove the shell without damaging the nut.

5. What are the safety precautions to consider when working in a nut processing facility?

Working in a nut processing facility requires adherence to strict safety precautions:

- Personal protective equipment (PPE): Gloves, safety glasses, hairnets, and protective clothing should be worn to prevent injuries and contamination.

- Machine safety: Operators should be trained and follow proper procedures when operating machinery to prevent accidents.

- Electrical safety: All electrical equipment should be properly maintained and inspected to prevent electrical hazards.

- Fire safety: Fire extinguishers and sprinklers should be readily available and inspected regularly.

- Food safety: Proper hygiene and sanitation practices should be followed to prevent food contamination.

6. How do you maintain the quality of nuts throughout the processing process?

Maintaining the quality of nuts throughout the processing process involves:

- Raw material inspection: Nuts are inspected upon arrival to ensure they meet quality standards.

- Sorting and grading: Nuts are sorted and graded to remove damaged or low-quality nuts.

- Proper storage and handling: Nuts are stored and handled properly to prevent spoilage and maintain freshness.

- Equipment maintenance: Processing equipment is regularly maintained and calibrated to ensure optimal performance.

- Quality control: Regular quality checks are conducted throughout the process to identify and correct any issues.

7. What are the common challenges encountered in nut processing and how do you overcome them?

Common challenges in nut processing include:

- Nut variability: Nuts can vary in size, shape, and moisture content, which can affect processing efficiency.

- Shell damage: Nuts can be damaged during cracking or shelling, which can reduce their value.

- Contamination: Nuts can be contaminated with foreign materials, pests, or microorganisms, which can compromise their safety and quality.

- Equipment breakdowns: Processing equipment can break down, causing delays and production losses.

- Seasonal availability: Nuts are typically harvested seasonally, which can impact processing schedules and availability.

8. Describe the different types of equipment used in nut processing and their functions?

Nut processing involves the use of various equipment, including:

- Sorting and grading machines: These machines separate nuts based on size, color, shape, and density.

- Crackers and shellers: These machines crack or remove the shells from nuts.

- Blanchers: These machines remove the skins or membranes from nuts.

- Roasting machines: These machines roast nuts to enhance their flavor and aroma.

- Packaging machines: These machines package nuts in various formats for storage and distribution.

9. What is the role of automation in modern nut processing facilities?

Automation plays a significant role in modern nut processing facilities:

- Increased efficiency: Automated processes reduce manual labor and increase production rates.

- Improved quality control: Automated systems can monitor and control processing parameters to ensure consistent quality.

- Reduced costs: Automation helps reduce labor costs and improve overall production efficiency.

- Enhanced safety: Automated systems can reduce the risk of accidents and injuries by minimizing human interaction with machinery.

10. How do you stay up-to-date on the latest advancements in nut processing technology?

I stay up-to-date on the latest advancements in nut processing technology through:

- Industry publications and journals: I regularly read trade magazines and research papers to stay informed about new technologies and best practices.

- Trade shows and conferences: I attend industry events to learn about new equipment, products, and innovations.

- Online research: I conduct online research and consult with industry experts to stay abreast of the latest developments.

- Continuing education: I participate in workshops, seminars, and training programs to expand my knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nut Process Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nut Process Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Nut Process Helper is responsible for assisting with the processing of nuts in a manufacturing environment. This role plays a crucial part in ensuring the efficient and safe production of high-quality nut products.

1. Preparing Raw Nuts

The Nut Process Helper is responsible for preparing raw nuts for processing. This includes:

- Inspecting nuts for defects, such as mold or damage.

- Removing shells and husks from nuts.

- Sorting nuts by size, variety, and grade.

2. Operating Processing Equipment

The Nut Process Helper operates a variety of processing equipment, including:

- Grading machines to separate nuts by size.

- Roasting machines to toast nuts.

- Cooling machines to cool nuts after roasting.

3. Packaging and Shipping Products

The Nut Process Helper is responsible for packaging and shipping nut products. This includes:

- Filling bags or containers with nuts.

- Labeling and sealing packages.

- Loading packages onto pallets.

4. Maintaining a Clean and Safe Work Environment

The Nut Process Helper is responsible for maintaining a clean and safe work environment. This includes:

- Cleaning work areas and equipment.

- Following safety protocols.

- Reporting any hazards or accidents.

Interview Tips

To ace an interview for a Nut Process Helper position, it is important to prepare and highlight your relevant skills and experience. Here are some tips:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Nut Process Helper position you are applying for. This will help you understand the company’s culture, goals, and the requirements of the role. You can find this information on the company’s website, social media pages, and job description.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience that make you a good fit for the Nut Process Helper position. This may include your experience in food processing, manufacturing, or customer service. You should also emphasize your attention to detail, safety-consciousness, and ability to work in a fast-paced environment.

4. Be Enthusiastic and Professional

It is important to be enthusiastic and professional during your interview. This shows the interviewer that you are interested in the position and that you are a hard worker. Be sure to make eye contact, dress appropriately, and arrive on time for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nut Process Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.