Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oil Well Service Operator Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

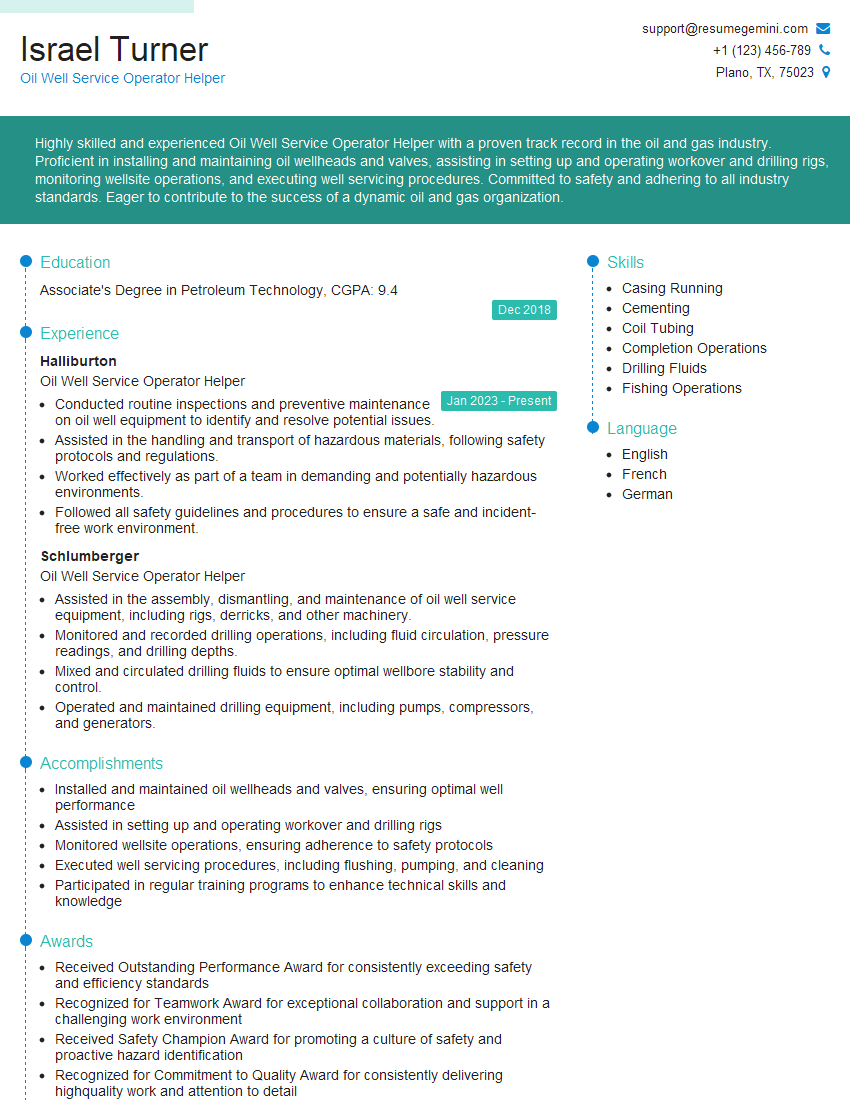

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Well Service Operator Helper

1. What are the different types of oil well service operations?

There are various oil well service operations, including:

- Well drilling: Using specialized equipment to create a borehole in the earth’s crust to reach underground oil and gas reserves.

- Well completion: Installing the necessary equipment and infrastructure, such as casings, tubing, and valves, to prepare the well for production.

- Well stimulation: Enhancing the flow of oil and gas from the reservoir by using techniques such as acidizing, fracturing, or injecting gas.

- Well maintenance: Performing regular inspections, repairs, and replacements to ensure the well’s integrity and optimal performance.

- Well abandonment: Plugging and sealing the well permanently once it has reached the end of its productive life.

2. Describe the safety protocols and regulations that must be followed during oil well service operations.

Personal Protective Equipment (PPE)

- Hard hat

- Safety glasses

- Ear protection

- Gloves

- Steel-toed boots

Worksite Safety

- Adhering to designated work areas

- Using proper lifting techniques

- Being aware of potential hazards, such as slips, trips, and falls

- Following emergency procedures in case of accidents or spills

Environmental Protection

- Preventing spills and leaks of hazardous materials

- Properly disposing of waste and wastewater

- Minimizing noise and light pollution

3. What are the key responsibilities of an Oil Well Service Operator Helper?

- Assisting with the preparation, assembly, and operation of equipment used in oil well service operations.

- Monitoring and maintaining equipment during operations to ensure proper functioning and safety.

- Performing routine maintenance and repairs on equipment as needed.

- Following safety protocols and procedures at all times.

- Working as part of a team to complete tasks efficiently and effectively.

- Communicating effectively with other team members and supervisors.

4. Describe your experience in handling and operating oilfield equipment such as pumps, valves, and tanks.

- Experience operating high-pressure pumps, ensuring proper flow rates and pressures for various operations.

- Familiarity with different types of valves, including ball valves, gate valves, and check valves, and the ability to operate them safely and effectively.

- Knowledge of storage tank operations, including filling, emptying, and maintaining proper levels of fluids or gases.

- Understanding of the principles of fluid dynamics and the ability to troubleshoot and resolve any issues related to equipment performance.

5. What are the common troubleshooting techniques you have used to resolve issues during oil well service operations?

- Identifying the problem: Observing the symptoms, gathering data, and using diagnostic tools to identify the root cause of the issue.

- Consulting documentation and resources: Referring to manuals, technical specifications, or experienced colleagues to find potential solutions.

- Isolating the issue: Disconnecting or bypassing components to determine which part of the system is causing the problem.

- Testing and verifying solutions: Implementing potential solutions and monitoring the results to verify if the issue has been resolved.

- Documenting and reporting: Recording the troubleshooting process, including the problem identified, steps taken, and the outcome, for future reference and improvement.

6. How do you ensure that oil well service equipment is maintained in optimal condition?

- Regular inspections: Conducting scheduled inspections to identify potential issues or signs of wear and tear.

- Preventive maintenance: Performing routine maintenance tasks, such as lubrication, cleaning, and adjustments, to prevent equipment failures.

- Condition monitoring: Using sensors and other monitoring devices to track equipment performance and identify any deviations from normal operating parameters.

- Equipment calibration: Ensuring that measuring and monitoring instruments are calibrated regularly to provide accurate readings.

- Spare parts management: Maintaining an inventory of critical spare parts to minimize downtime in case of equipment failures.

7. What are your strengths and weaknesses as an Oil Well Service Operator Helper?

Strengths:

- Strong work ethic and dedication to safety

- Ability to work effectively in a team environment

- Good mechanical aptitude and problem-solving skills

- Experience in operating and maintaining oilfield equipment

- Excellent communication and interpersonal skills

Weaknesses:

- Limited experience in certain specialized oil well service operations

- Working in extreme weather conditions can be challenging

- Need to improve knowledge of electrical systems

8. How do you stay up-to-date on the latest industry developments and best practices in oil well servicing?

- Attending industry conferences and workshops

- Reading trade publications and technical journals

- Participating in online forums and discussions

- Consulting with experienced professionals and mentors

- Undertaking additional training and certification programs

9. Can you describe a challenging situation you faced while working as an Oil Well Service Operator Helper and how you overcame it?

In a previous role, I encountered a situation where a high-pressure pump malfunctioned during a well stimulation operation. The issue caused a significant drop in pressure, potentially jeopardizing the success of the operation. I quickly diagnosed the problem by isolating the faulty component and consulting with a senior technician. Together, we identified the root cause and replaced the defective part, ensuring the operation was completed successfully with minimal downtime.

10. Why are you interested in working as an Oil Well Service Operator Helper for our company?

I am eager to join your company because of its reputation as a leader in the oil and gas industry. I am particularly drawn to your commitment to safety, environmental stewardship, and technological innovation. I believe that my skills and experience would be a valuable asset to your team, and I am excited about the opportunity to contribute to your ongoing success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Well Service Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Well Service Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Oil Well Service Operator Helper, your primary responsibilities will revolve around assisting experienced operators in the maintenance and operation of oil well equipment.

1. Assist in Equipment Operation

You will be involved in the operation of various oil well equipment, such as pumps, flow lines, and valves.

- Monitor equipment performance and report any abnormalities to the operator.

- Follow established procedures for equipment operation and maintenance.

2. Maintain Equipment and Work Area

Maintaining a clean and organized work environment is crucial for safety and efficiency.

- Clean and lubricate equipment as needed.

- Keep work areas clear of debris and potential hazards.

3. Participate in Well Service Operations

You will assist in various well service operations, such as well stimulation and completion.

- Help prepare and mix chemicals and fluids used in well services.

- Handle and transport equipment and materials to and from the well site.

4. Safety and Compliance

Adhering to safety protocols and industry regulations is paramount in this role.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety procedures and guidelines.

Interview Tips

To ace your interview for an Oil Well Service Operator Helper position, consider these tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the oil well service industry by researching their history, operations, and recent developments.

- Visit the company website and social media pages.

- Read industry news and articles to stay informed about trends and best practices.

2. Highlight Relevant Skills and Experience

Emphasize your abilities and previous experience related to oil well service or related fields.

- Discuss your hands-on experience with equipment operation, maintenance, and safety procedures.

- If you have experience in the oil and gas industry, mention it and explain how it has prepared you for this role.

3. Demonstrate Safety Mindset

Safety is of utmost importance in the oil well service industry. Communicate your commitment to safety and your understanding of safety protocols.

- Explain how you prioritize safety in your work and follow established procedures.

- Share examples of your involvement in safety training and initiatives.

4. Show Willingness to Learn and Grow

The oil well service industry is constantly evolving. Express your eagerness to learn new technologies and techniques, and to contribute to continuous improvement.

- Discuss your interest in attending industry workshops or training programs.

- Explain how you stay updated with industry advancements through reading materials or online resources.

Next Step:

Now that you’re armed with the knowledge of Oil Well Service Operator Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Oil Well Service Operator Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini