Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Reduction Furnace Operator Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

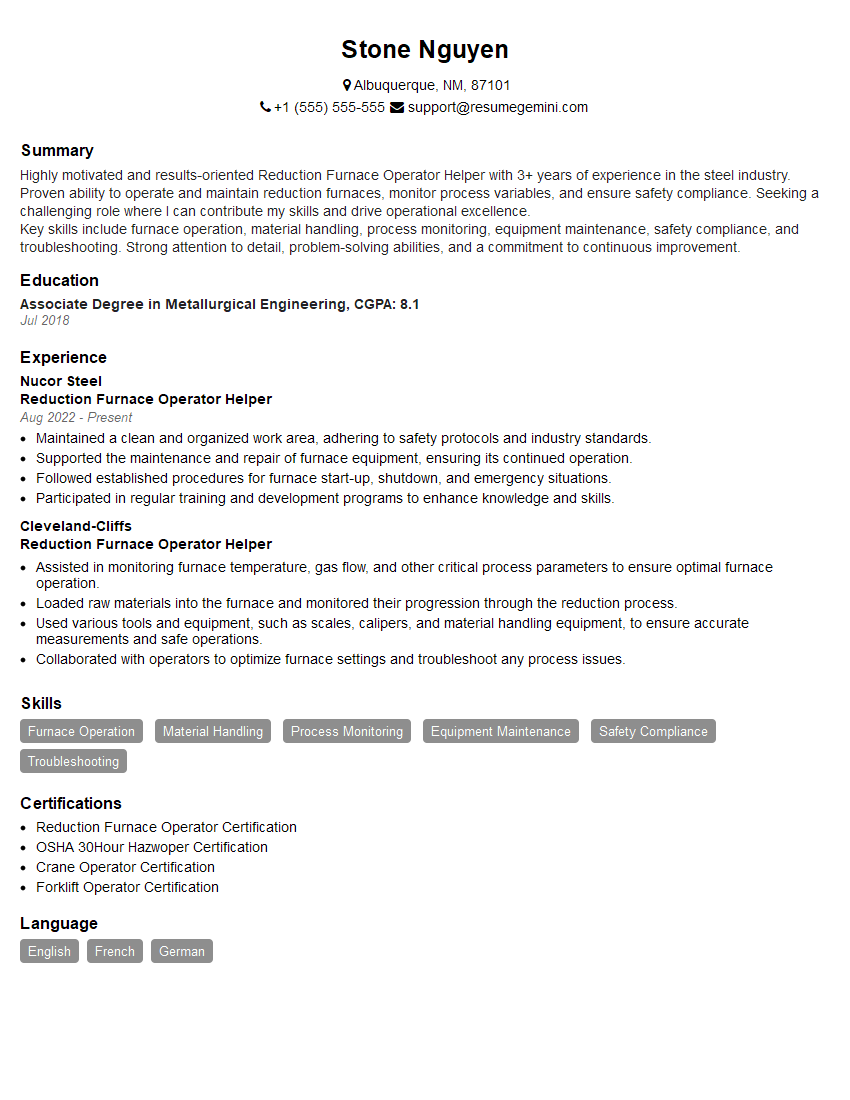

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reduction Furnace Operator Helper

1. Describe the process of charging the reduction furnace and the safety precautions to be taken during charging?

The process of charging the reduction furnace involves adding raw materials, such as iron ore, coke, and limestone, into the furnace. Safety precautions during charging include:

- Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and a hard hat.

- Ensuring that the furnace is properly vented to prevent the accumulation of toxic gases.

- Using a charging machine to load the materials into the furnace, rather than manually handling them.

- Monitoring the temperature of the furnace to prevent overheating.

- Maintaining a clean and organized work area to prevent accidents.

2. Explain the role of the tuyere in the reduction process and how to adjust it?

Tuyere design and maintenance:

- The tuyere is a critical component of the reduction furnace, responsible for injecting preheated air into the furnace.

- The design of the tuyere must ensure that air is injected at the correct velocity and angle to promote efficient combustion and reduce the formation of undesirable by-products.

- Regular maintenance, including cleaning and replacing worn parts, is crucial to maintain optimal tuyere performance.

Tuyere adjustment:

- Adjusting the tuyere involves changing its position or angle to optimize the air flow and combustion process.

- The position and angle of the tuyere can be adjusted using specialized tools or automated systems.

- Proper adjustment helps to improve the efficiency of the reduction process, reduce energy consumption, and minimize emissions.

3. What are the key indicators of furnace performance and how to monitor them?

Key indicators of furnace performance include:

- Furnace temperature: The temperature inside the furnace is critical for the reduction process and must be closely monitored to ensure optimal conditions.

- Air flow rate: The amount of air injected into the furnace affects the combustion process and must be regulated to maintain the desired temperature and reduce emissions.

- Fuel consumption: Monitoring fuel consumption helps to optimize the efficiency of the furnace and reduce operating costs.

- Slag composition: The composition of the slag, a byproduct of the reduction process, provides insights into the efficiency of the furnace and the quality of the metal being produced.

- Gas composition: Analyzing the composition of the gases produced during the reduction process can indicate the efficiency of the combustion process and identify potential issues.

4. Describe the procedure for taking a metal sample from the furnace and the quality checks to be performed on the sample?

The procedure for taking a metal sample from the furnace involves:

- Preparing the sampling equipment, including a sampling spoon or lance, and a mold to hold the sample.

- Taking a sample from the furnace at a predetermined location and time, ensuring that the sample is representative of the molten metal.

- Pouring the molten metal sample into the mold and allowing it to solidify.

- Once solidified, the sample is analyzed using various techniques, such as chemical analysis or spectrographic analysis, to determine its composition and quality.

5. Explain the importance of slag control in the reduction process?

Slag control is crucial in the reduction process because slag acts as:

- A protective layer on the surface of the molten metal, preventing oxidation and heat loss.

- A medium for absorbing impurities and undesirable elements from the molten metal, improving its quality.

- An indicator of the furnace’s operating conditions and the efficiency of the reduction process.

- By monitoring and controlling the slag composition, operators can optimize the furnace performance, reduce energy consumption, and improve the quality of the produced metal.

6. What are the common problems encountered in the operation of a reduction furnace and how to troubleshoot them?

Common problems encountered in the operation of a reduction furnace include:

- Furnace overheating: This can be caused by insufficient cooling, excessive fuel consumption, or blockage of air flow. Troubleshooting involves identifying the root cause and implementing corrective measures, such as increasing cooling, reducing fuel input, or clearing any obstructions.

- Slag formation: Excessive slag formation can hinder the reduction process and reduce efficiency. Troubleshooting involves adjusting the slag composition, optimizing the furnace temperature, and ensuring proper slag removal.

- Metal contamination: Impurities in the raw materials or improper furnace operation can lead to metal contamination. Troubleshooting involves identifying the source of contamination and implementing measures to minimize its impact on the metal quality.

7. Discuss the environmental regulations related to the operation of a reduction furnace?

Environmental regulations related to the operation of a reduction furnace include:

- Air pollution control: Regulations aim to minimize the emission of harmful gases, such as sulfur dioxide and nitrogen oxides, into the atmosphere.

- Water pollution control: Regulations focus on preventing the discharge of wastewater containing heavy metals and other pollutants into water bodies.

- Waste management: Regulations govern the disposal and recycling of hazardous waste generated during the operation of the furnace, such as slag and dust.

8. Describe your experience in working with automated systems in a reduction furnace operation?

In my previous role as a Reduction Furnace Operator Helper, I was responsible for monitoring and operating various automated systems, including:

- Temperature control systems: These systems automatically adjust the fuel flow to maintain the desired furnace temperature.

- Air flow control systems: These systems regulate the flow of air into the furnace to optimize combustion and reduce emissions.

- Slag removal systems: These systems automatically remove slag from the furnace, ensuring optimal slag control and preventing furnace damage.

- Safety interlock systems: These systems ensure that the furnace is operating safely by automatically shutting down the furnace in case of any hazardous conditions.

9. What are your strengths and weaknesses as a Reduction Furnace Operator Helper?

Strengths:

- Strong understanding of the reduction furnace process and its operating parameters.

- Proven ability to monitor and control automated systems effectively.

- Excellent teamwork and communication skills.

- Meticulous attention to detail and commitment to safety.

- Proactive approach to problem-solving and troubleshooting.

Weaknesses:

- Limited experience in operating large-scale reduction furnaces.

- Need to improve my knowledge of slag chemistry and its impact on furnace performance.

10. Why are you interested in this Reduction Furnace Operator Helper position?

I am eager to join your team as a Reduction Furnace Operator Helper because I am passionate about the steel industry and believe that my skills and experience align well with the requirements of this role. I am confident that I can contribute to the efficient and safe operation of your reduction furnace, supporting the production of high-quality steel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reduction Furnace Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reduction Furnace Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Reduction Furnace Operator Helper is responsible for assisting the operator in the safe and efficient operation of a reduction furnace. Their duties include:

1. Preparing the Furnace

• Loading the furnace with raw materials

• Setting up the furnace controls

2. Operating the Furnace

• Monitoring the furnace temperature and pressure

• Adjusting the furnace controls to maintain optimal conditions

3. Unloading the Furnace

• Removing the finished product from the furnace

• Cleaning and inspecting the furnace

4. Maintaining the Furnace

• Performing routine maintenance on the furnace

• Troubleshooting and repairing minor problems

Interview Tips

To ace an interview for a Reduction Furnace Operator Helper position, it is important to:

1. Research the Company and the Position

• Visit the company’s website to learn about their history, products, and services.

• Read online reviews of the company to get a sense of its culture and work environment.

2. Prepare Answers to Common Interview Questions

• Practice answering questions about your experience, skills, and qualifications.

• Use the STAR method to answer questions about your past experiences.

3. Dress Professionally and Arrive on Time

• First impressions matter, so dress appropriately for the interview.

• Punctuality shows that you are respectful of the interviewer’s time.

4. Be Enthusiastic and Engaged

• Show the interviewer that you are interested in the position and the company.

• Ask thoughtful questions about the role and the company.

5. Follow Up

• Send a thank-you note to the interviewer after the interview.

• If you do not hear back within a week, follow up with the interviewer to inquire about the status of your application.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Reduction Furnace Operator Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Reduction Furnace Operator Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.