Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pulverizer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pulverizer so you can tailor your answers to impress potential employers.

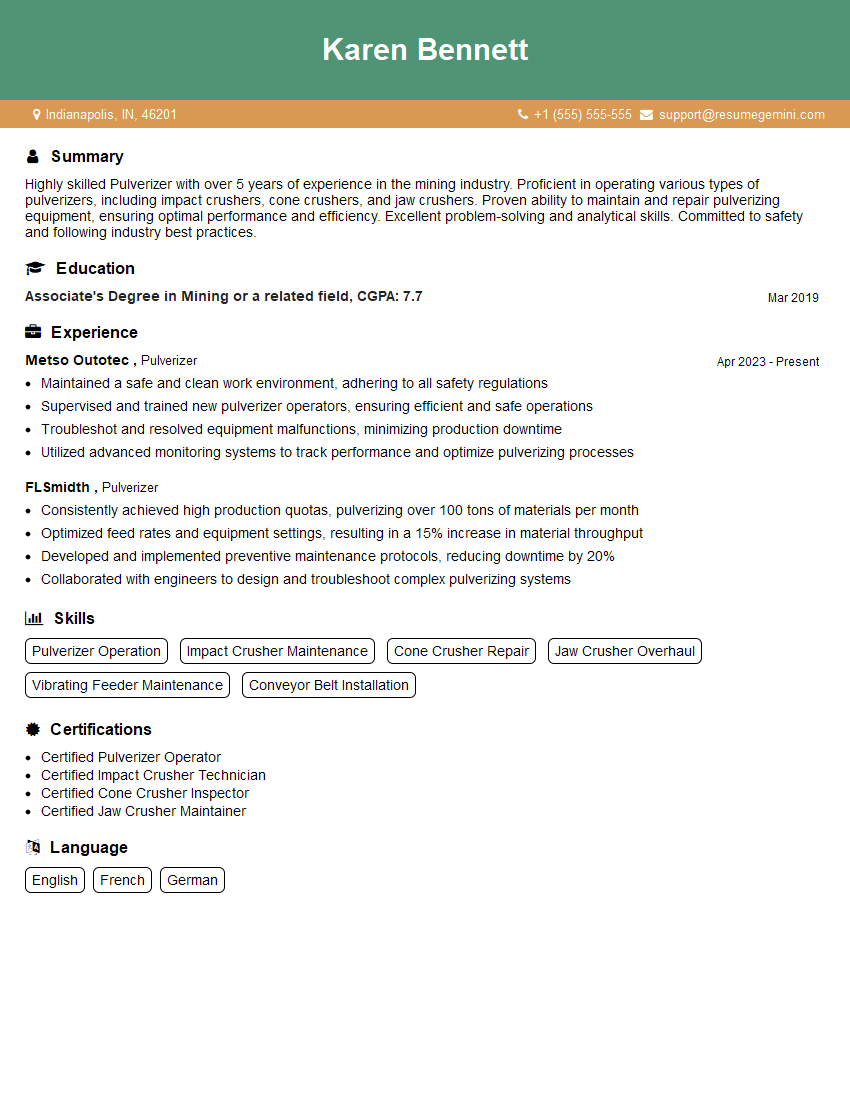

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulverizer

1. What are the key components of a pulverizer and how do they work together to achieve the desired particle size?

The key components of a pulverizer include the feed mechanism, the grinding chamber, the grinding element, and the discharge mechanism. The feed mechanism delivers the material to be pulverized into the grinding chamber, where it is pulverized by the grinding element. The grinding element can be a rotating disk or a fixed anvil, and the material is pulverized by impact or shear forces. The discharge mechanism removes the pulverized material from the grinding chamber.

2. Explain the different types of pulverizers and their respective advantages and disadvantages.

Impact Pulverizers

- Advantages: High capacity, low energy consumption, simple design

- Disadvantages: Limited particle size reduction, can produce excessive dust

Attrition Pulverizers

- Advantages: Can achieve very fine particle sizes, low noise and vibration

- Disadvantages: Low capacity, high energy consumption, complex design

Fluidized Bed Pulverizers

- Advantages: Can process heat-sensitive materials, uniform particle size distribution

- Disadvantages: Complex design, high operating costs

3. How would you determine the optimal operating parameters for a pulverizer to achieve the desired particle size and minimize energy consumption?

To determine the optimal operating parameters for a pulverizer, I would consider the following factors:

- Material properties: Hardness, toughness, moisture content

- Desired particle size: Target size range

- Pulverizer type: Impact, attrition, fluidized bed

- Energy efficiency: Minimize power consumption

I would conduct experimental tests to determine the relationship between operating parameters (e.g., feed rate, grinding element speed, air flow rate) and particle size and energy consumption. Based on the test results, I would optimize the operating parameters to achieve the desired particle size while minimizing energy consumption.

4. What are the common maintenance procedures for a pulverizer and how often should they be performed?

Common maintenance procedures for a pulverizer include:

- Regular inspection of wear parts (e.g., grinding elements, liners)

- Lubrication of moving components

- Calibration of sensors

- Cleaning of the grinding chamber and discharge mechanism

The frequency of maintenance procedures depends on the operating conditions and the manufacturer’s recommendations. However, it is generally recommended to perform regular inspections and maintenance every 6-12 months to ensure optimal performance and prevent premature wear or failure.

5. How would you troubleshoot common problems encountered with pulverizers?

Common problems encountered with pulverizers include:

- Excessive wear of grinding elements

- Clogging of the discharge mechanism

- Overheating of the grinding chamber

- Vibration or noise

- Insufficient particle size reduction

To troubleshoot these problems, I would follow these steps:

- Inspect the pulverizer for any visible damage or wear

- Check the operating parameters (e.g., feed rate, grinding element speed) to ensure they are within the recommended range

- Clean the grinding chamber and discharge mechanism

- Lubricate all moving components

- Calibrate the sensors

If these steps do not resolve the problem, I would contact the manufacturer for further assistance.

6. What safety precautions should be taken when operating or maintaining a pulverizer?

When operating or maintaining a pulverizer, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves

- Ensure that the pulverizer is properly grounded

- Do not operate the pulverizer in an explosive or flammable environment

- Keep the work area clean and free of debris

- Do not attempt to repair or maintain the pulverizer while it is running

- Follow all manufacturer’s instructions for operation and maintenance

7. How do you stay updated on the latest advancements in pulverizer technology and industry best practices?

To stay updated on the latest advancements in pulverizer technology and industry best practices, I regularly engage in the following activities:

- Attend industry conferences and exhibitions

- Read technical journals and publications

- Attend webinars and online training programs

- Network with other professionals in the field

- Visit manufacturer websites to learn about new products and technologies

8. How would you design a pulverizing system for a specific application, considering factors such as material properties, desired particle size, and production capacity?

To design a pulverizing system for a specific application, I would follow these steps:

- Analyze the material properties (e.g., hardness, toughness, moisture content)

- Determine the desired particle size range

- Estimate the required production capacity

- Select a suitable pulverizer type based on the material properties, particle size requirements, and production capacity

- Determine the appropriate operating parameters for the pulverizer (e.g., feed rate, grinding element speed)

- Design the ancillary equipment, such as the feed system, discharge system, and dust collection system

- Consider safety features and maintenance requirements

9. How would you assess the performance of a pulverizing system and identify areas for improvement?

To assess the performance of a pulverizing system, I would use the following metrics:

- Particle size distribution

- Production capacity

- Energy consumption

- Maintenance requirements

I would compare the actual performance to the desired performance and identify any areas where the system is not meeting expectations. I would then investigate the possible causes of the performance issues and develop recommendations for improvement.

10. What are the emerging trends in pulverizing technology and how do you anticipate these trends will impact the industry?

Emerging trends in pulverizing technology include:

- Increased use of automation and control systems

- Development of new grinding materials and techniques

- Focus on energy efficiency and sustainability

- Integration of pulverizing systems with other manufacturing processes

These trends are expected to have a significant impact on the industry, leading to improved productivity, reduced costs, and increased sustainability. I believe that it is important to stay abreast of these trends and to be prepared to adopt new technologies as they emerge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulverizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulverizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulverizers are responsible for operating and maintaining pulverizing equipment to grind materials into a fine powder. They perform a range of tasks to ensure the smooth operation of the pulverizing process, including:

1. Equipment Operation

Pulverizers are responsible for operating various types of pulverizing equipment, including ball mills, hammer mills, and air classifiers. They must be familiar with the operating procedures and safety protocols for each type of equipment.

- Starting up, adjusting, and shutting down pulverizing equipment

- Monitoring equipment performance to ensure it is operating efficiently

- Troubleshooting and performing minor repairs on equipment

2. Material Handling

Pulverizers are also responsible for handling the materials that are being pulverized. This includes loading materials into the equipment, monitoring the feed rate, and collecting the finished product.

- Loading materials into the pulverizing equipment

- Monitoring the feed rate to ensure the equipment is operating efficiently

- Collecting the finished product and storing it in appropriate containers

3. Quality Control

Pulverizers are responsible for ensuring that the pulverized product meets the required quality specifications. This includes testing the product for particle size, moisture content, and other relevant properties.

- Testing the pulverized product for particle size

- Testing the pulverized product for moisture content

- Testing the pulverized product for other relevant properties

4. Maintenance and Repairs

Pulverizers are responsible for maintaining and repairing the pulverizing equipment. This includes performing routine maintenance tasks, such as cleaning, lubricating, and inspecting equipment. They must also be able to troubleshoot and repair equipment problems.

- Performing routine maintenance tasks on the pulverizing equipment

- Troubleshooting and repairing equipment problems

- Replacing worn or damaged parts

Interview Tips

To prepare for an interview for a Pulverizer position, it is important to:

1. Research the company and the position

Research the company’s website, social media pages, and industry publications to learn about its culture, values, and business objectives. This will help you understand the company’s needs and how your skills and experience can align with them.

- Read the job description carefully and identify the key responsibilities and qualifications required for the role.

- Prepare examples from your previous work experience that demonstrate your ability to meet the job requirements.

2. Practice your answers to common interview questions

Some common interview questions that you may be asked include:

- Tell me about your experience operating and maintaining pulverizing equipment.

- How do you ensure that the pulverized product meets the required quality specifications?

- What are your strengths and weaknesses as a Pulverizer?

It is beneficial to practice your answers to these questions in advance so that you can deliver them confidently and concisely during the interview.

3. Be prepared to talk about your safety knowledge and experience

Pulverizing equipment can be hazardous, so it is important to be familiar with the safety protocols and procedures for operating and maintaining the equipment. Be prepared to discuss your safety knowledge and experience during the interview.

- Review the Occupational Safety and Health Administration (OSHA) regulations for pulverizing equipment.

- Describe your experience with following safety protocols and procedures.

4. Be prepared to discuss your problem-solving skills

Pulverizers often encounter problems with the equipment they operate. Be prepared to discuss your problem-solving skills and how you would troubleshoot and resolve common problems.

- Describe a time when you successfully troubleshoot and resolved a problem with pulverizing equipment.

- Explain your approach to problem-solving and how you would apply it to the role of Pulverizer.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pulverizer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pulverizer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.