Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Specialty Finishing Utility Person position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

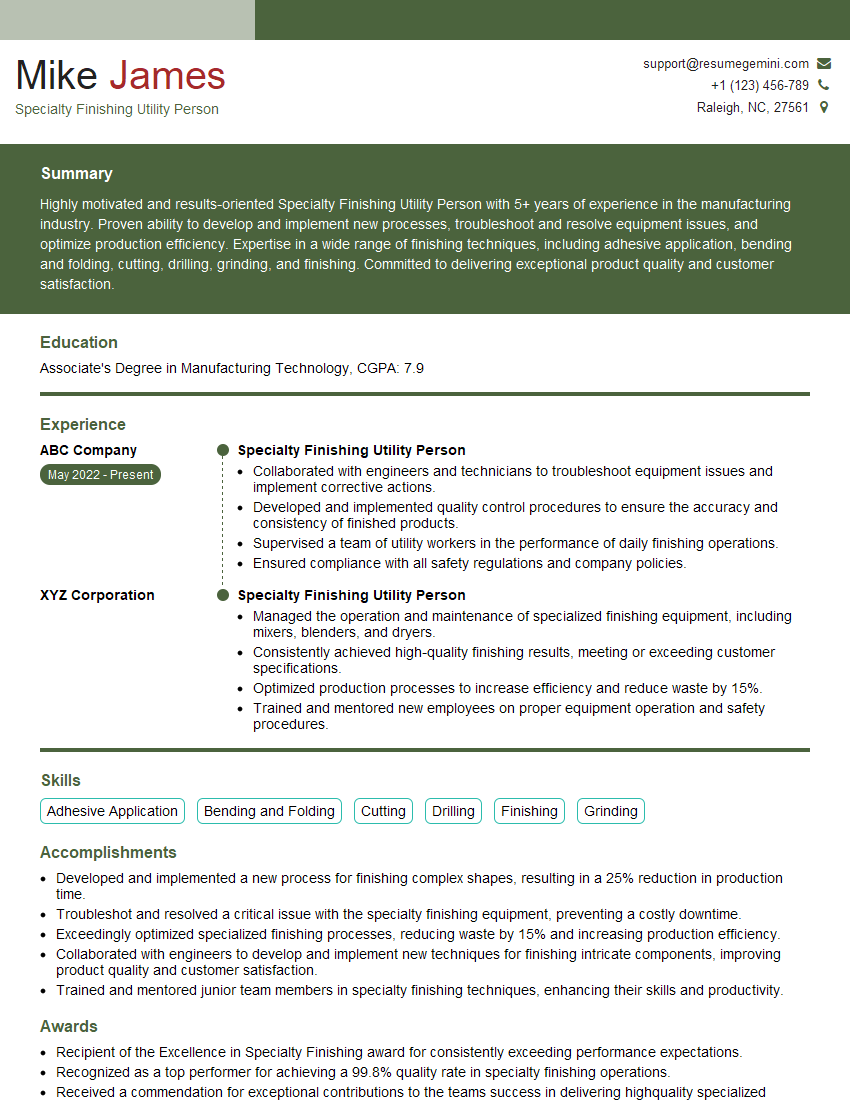

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Specialty Finishing Utility Person

1. What is the proper procedure for preparing a surface for finishing?

To properly prepare a surface for finishing, I follow a systematic process that includes:

- Cleaning the surface to remove any dirt, grease, or other contaminants

- Sanding the surface to create a smooth and even surface

- Applying a primer or undercoat to protect the surface and enhance adhesion

2. What are the different types of finishing techniques and when to use them?

Spray finishing

- Used for large surfaces or complex shapes

- Provides a uniform and consistent finish

Brush finishing

- Suitable for small or intricate areas

- Allows for precise application and detailing

Roller finishing

- Efficient for large, flat surfaces

- Provides a smooth, even finish

3. What are the different types of finishes and their applications?

The type of finish I choose depends on the desired appearance, durability, and functionality of the surface:

- Gloss finish: Provides a shiny, reflective surface, often used for decorative purposes

- Satin finish: Offers a subtle sheen, suitable for both indoor and outdoor applications

- Matte finish: Produces a non-reflective, flat surface, ideal for hiding imperfections

4. How do you ensure the color consistency and accuracy when mixing and applying finishes?

To ensure color consistency and accuracy, I adhere to the following practices:

- Using a colorimeter to accurately measure and match colors

- Following specific mixing ratios and application techniques

- Creating test swatches to verify color accuracy before full application

5. What are the safety precautions that should be taken when working with finishing materials?

I prioritize safety by adhering to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including gloves, masks, and safety glasses

- Ensuring adequate ventilation to avoid inhalation of fumes

- Storing and handling chemicals properly to prevent spills and accidents

6. How do you troubleshoot common finishing problems, such as runs, sags, or bubbling?

To troubleshoot common finishing problems, I employ the following strategies:

- Runs and sags: Adjusting the viscosity of the finish, reducing the application thickness, and using a brush with softer bristles

- Bubbling: Ensuring proper surface preparation, removing trapped air before application, and using a foam roller

7. What are the latest advancements and trends in finishing techniques?

I stay updated with industry advancements by:

- Attending trade shows and workshops

- Reading industry publications and online resources

- Consulting with manufacturers and suppliers for technical advice

8. How do you handle working with different types of substrates, such as wood, metal, or plastic?

To effectively work with different substrates, I:

- Identify the substrate’s specific characteristics and finishing requirements

- Select appropriate finishes and application techniques that are compatible with the substrate

- Adjust my techniques to achieve optimal adhesion and durability

9. What is your approach to achieving a high-quality finish that meets customer expectations?

I approach high-quality finishing by:

- Paying meticulous attention to detail and following best practices

- Communicating effectively with customers to understand their requirements

- Conducting thorough inspections and quality checks throughout the finishing process

10. How do you prioritize tasks and manage your time effectively in a fast-paced finishing environment?

In a fast-paced environment, I prioritize tasks and manage my time effectively by:

- Creating a structured work schedule and setting clear deadlines

- Prioritizing urgent tasks and delegating responsibilities when necessary

- Utilizing time management techniques, such as the Pomodoro Technique

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Specialty Finishing Utility Person.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Specialty Finishing Utility Person‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Specialty Finishing Utility Person is responsible for a wide range of tasks in the manufacturing process, including operating and monitoring specialized finishing machinery, performing quality control checks, and ensuring the smooth flow of materials and products throughout the production line.

1. Specialized Finishing Machinery

Operate and maintain specialized finishing machinery, such as polishing machines, sanding machines, and coating machines, to achieve desired surface finishes on manufactured parts and products.

- Configure and adjust machinery settings to meet specific product requirements.

- Troubleshoot and resolve operational issues to ensure efficient machinery operation.

2. Quality Control

Conduct quality control checks on finished products to ensure they meet established specifications and customer requirements.

- Inspect products for defects, surface imperfections, and dimensional accuracy.

- Identify and document non-conforming products and initiate corrective actions as needed.

3. Material Handling

Handle and move materials, products, and equipment throughout the production area, using manual or mechanical handling methods.

- Load and unload materials into machinery and transport finished products to designated areas.

- Maintain a clean and organized work area to ensure safety and efficiency.

4. Production Support

Assist with other production-related tasks as required, such as setup, cleaning, and equipment maintenance.

- Participate in continuous improvement initiatives to optimize production processes.

- Adhere to safety regulations and company policies to maintain a safe and compliant work environment.

Interview Tips

Preparing for an interview for a Specialty Finishing Utility Person role requires thorough research and a well-structured approach. Here are some tips to help you ace the interview:

1. Research the Company and Role

Take the time to research the company and the specific role you are applying for. Visit the company’s website, read industry publications, and connect with current or former employees to gain insights into the company culture, products, and expectations for the position.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your answers in advance. Focus on highlighting your skills and experience that are most relevant to the job description, and be ready to provide specific examples to support your claims.

3. Be Enthusiastic and Professional

Convey your enthusiasm for the role and the company during the interview. Show that you are passionate about manufacturing and eager to contribute to the team’s success. Maintain a professional demeanor throughout the interview, dress appropriately, and arrive on time.

4. Ask Questions

At the end of the interview, take the opportunity to ask thoughtful questions about the company, the role, and the team. This shows that you are engaged and interested in learning more about the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Specialty Finishing Utility Person, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Specialty Finishing Utility Person positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.