Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stone Driller Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

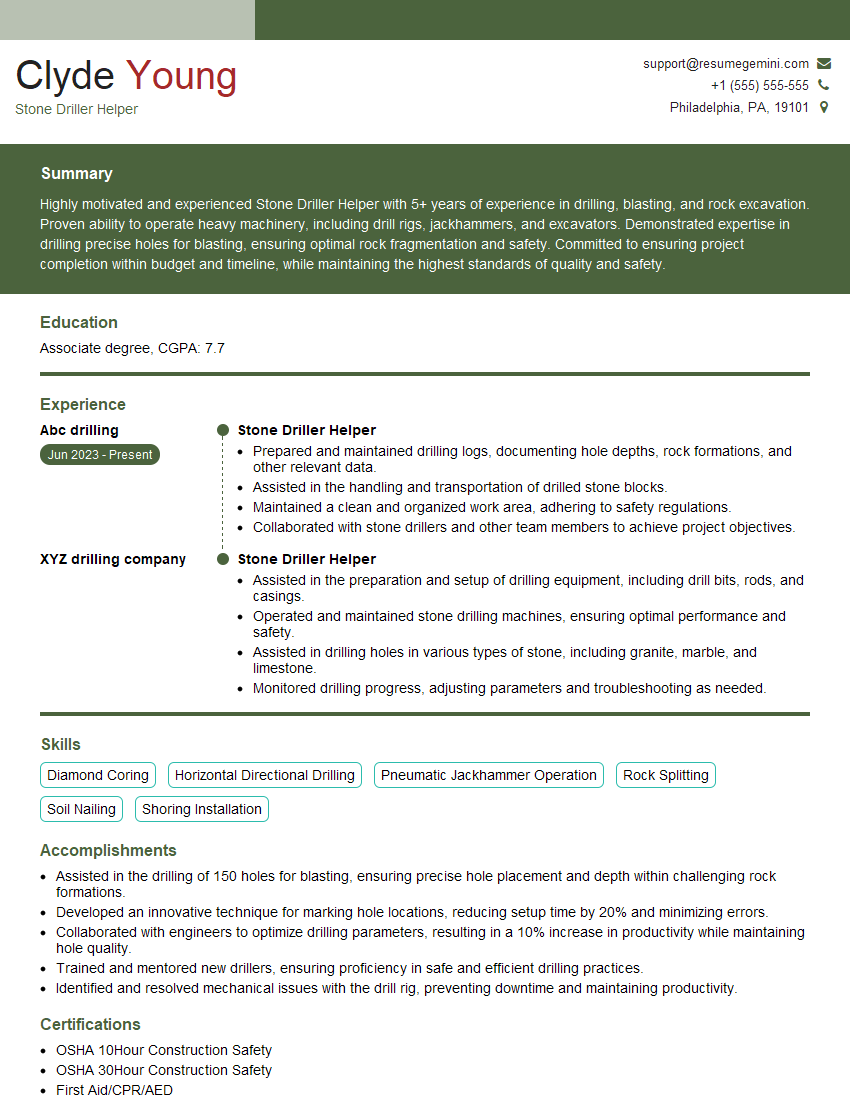

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stone Driller Helper

1. What are the different types of stone drilling equipment and their uses?

- Hand-held drills: These are small, portable drills that are typically used for drilling small holes in stone. They are powered by electricity or compressed air.

- Column drills: These are larger, stationary drills that are used for drilling larger holes in stone. They are typically powered by electricity.

- Radial arm drills: These are large, powerful drills that are used for drilling very large holes in stone. They are typically powered by electricity or hydraulics.

- Core drills: These are specialized drills that are used for drilling cylindrical holes in stone. They are typically used for extracting samples of stone for testing purposes.

2. What are the safety precautions that must be taken when operating stone drilling equipment?

subheading of the answer

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Ensure that the drill is properly secured and stable before operating it.

- Do not operate the drill if it is damaged or malfunctioning.

- Never leave the drill unattended while it is operating.

- Be aware of the surroundings and be cautious of other workers and objects in the area.

subheading of the answer

- Follow the manufacturer’s instructions for operating the drill.

- Never attempt to repair the drill yourself unless you are qualified to do so.

- Inspect the drill regularly and have it serviced as needed to prevent accidents.

- Store the drill in a safe place when it is not in use.

3. What are the different types of stone drilling bits and their uses?

- Carbide-tipped bits: These bits are made of carbide, a very hard material that is resistant to wear. They are used for drilling in hard stones, such as granite and marble.

- Diamond-tipped bits: These bits are made of diamond, the hardest known material. They are used for drilling in very hard stones, such as concrete and reinforced concrete.

- Tungsten carbide-tipped bits: These bits are made of tungsten carbide, a hard material that is more resistant to wear than carbide. They are used for drilling in medium-hard stones, such as limestone and sandstone.

- Masonry bits: These bits are made of steel and are designed for drilling in soft stones, such as brick and mortar.

4. How do you determine the correct drill bit size for a particular stone drilling application?

- Consider the type of stone you are drilling.

- Consider the size of the hole you need to drill.

- Consult the manufacturer’s recommendations for the drill bit size.

- Use a test bit to determine the correct size before drilling the final hole.

5. What are the different techniques for drilling holes in stone?

- Hammer drilling: This is the most common technique for drilling holes in stone. It involves using a hammer drill to create a series of small holes in the stone.

- Rotary drilling: This technique involves using a rotary drill to drill a hole in the stone. It is typically used for drilling larger holes.

- Core drilling: This technique involves using a core drill to extract a cylindrical core of stone from the stone. It is typically used for obtaining samples of stone for testing purposes.

6. What are the different types of stone drilling fluids and their uses?

- Water: Water is the most common stone drilling fluid. It is used to cool the drill bit and to remove cuttings from the hole.

- Oil-based fluids: Oil-based fluids are used to lubricate the drill bit and to prevent cuttings from sticking to the drill bit.

- Synthetic fluids: Synthetic fluids are used for drilling in difficult conditions, such as when drilling in hard or abrasive stones.

7. How do you maintain stone drilling equipment?

- Clean the drill bit regularly to remove cuttings and debris.

- Lubricate the drill bit regularly to prevent wear and tear.

- Inspect the drill bit regularly for wear and damage.

- Replace the drill bit when it is worn or damaged.

- Follow the manufacturer’s instructions for maintaining the drill.

8. What are the different types of stone drilling rigs and their uses?

- Hand-held rigs: These rigs are small and portable, and are used for drilling small holes in stone.

- Column rigs: These rigs are larger and more powerful than hand-held rigs, and are used for drilling larger holes in stone.

- Radial arm rigs: These rigs are the largest and most powerful type of stone drilling rig, and are used for drilling very large holes in stone.

9. What are the different types of stone drilling methods and their advantages and disadvantages?

- Rotary drilling: This is the most common stone drilling method, and involves using a rotary drill to create a hole in the stone. It is relatively fast and efficient, but can be noisy and dusty.

- Percussion drilling: This method involves using a percussion drill to create a hole in the stone. It is less noisy and dusty than rotary drilling, but is slower and less efficient.

- Core drilling: This method involves using a core drill to extract a cylindrical core of stone from the stone. It is used for obtaining samples of stone for testing purposes, and is relatively slow and expensive.

10. What are the different types of stone drilling accessories and their uses?

- Drill bits: Drill bits are the cutting tools used in stone drilling. They are available in a variety of sizes and shapes to accommodate different drilling applications.

- Drilling fluids: Drilling fluids are used to cool the drill bit and to remove cuttings from the hole. They are available in a variety of types, including water, oil, and synthetic fluids.

- Drilling rigs: Drilling rigs are used to hold the drill bit and to provide power for drilling. They are available in a variety of sizes and types to accommodate different drilling applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stone Driller Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stone Driller Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stone Driller Helper is responsible for assisting a Stone Driller in various tasks related to drilling operations. The key responsibilities of this role include:

1. Equipment Handling

Assisting in the setup, maintenance, and operation of drilling equipment.

- Loading and unloading drill rods.

- Lubricating and cleaning equipment.

2. Drilling Operations

Supporting the Stone Driller during drilling operations.

- Mixing and handling drilling fluids.

- Controlling drilling parameters.

3. Core Handling

Handling and storing drill cores.

- Extracting and inspecting cores.

- Preparing cores for analysis.

4. Safety and Regulations

Ensuring compliance with safety regulations and guidelines.

- Wearing appropriate personal protective equipment.

- Following established drilling procedures.

Interview Tips

To ace an interview for a Stone Driller Helper position, consider the following tips:

1. Research the Company and Position

Gather information about the company and the specific role you’re applying for. This will give you a better understanding of the company’s culture, industry, and expectations for the position.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Emphasize Relevant Skills and Experience

Highlight your skills and experience that are relevant to the job description. Use specific examples to demonstrate your abilities in areas such as equipment handling, drilling operations, and safety protocols.

- Quantify your accomplishments using numbers and metrics whenever possible.

- Use action verbs and industry-specific terminology.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that showcase your qualifications and enthusiasm for the role. Consider practicing your answers with a friend or family member.

- Example Outline:

- Tell me about yourself and why you’re interested in this position.

- Describe your experience in drilling operations.

- How do you handle working in a team environment?

- What are your safety priorities on a drilling site?

4. Ask Informed Questions

Asking intelligent questions at the end of the interview demonstrates your interest and engagement. It also gives you an opportunity to clarify any details or learn more about the role and company.

- Example Questions:

- Could you describe the typical day-to-day responsibilities of a Stone Driller Helper?

- What are the opportunities for professional development within the company?

- How does the company prioritize safety on drilling sites?

5. Follow Up and Thank You Note

After the interview, send a brief thank-you note to the interviewer. This shows your appreciation and continued interest in the position. You can also reiterate your key qualifications and highlight your enthusiasm for the opportunity.

- Keep it concise and professional.

- Reiterate your interest in the position.

- Thank the interviewer for their time and consideration.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Stone Driller Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Stone Driller Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.