Feeling lost in a sea of interview questions? Landed that dream interview for Toolroom Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Toolroom Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

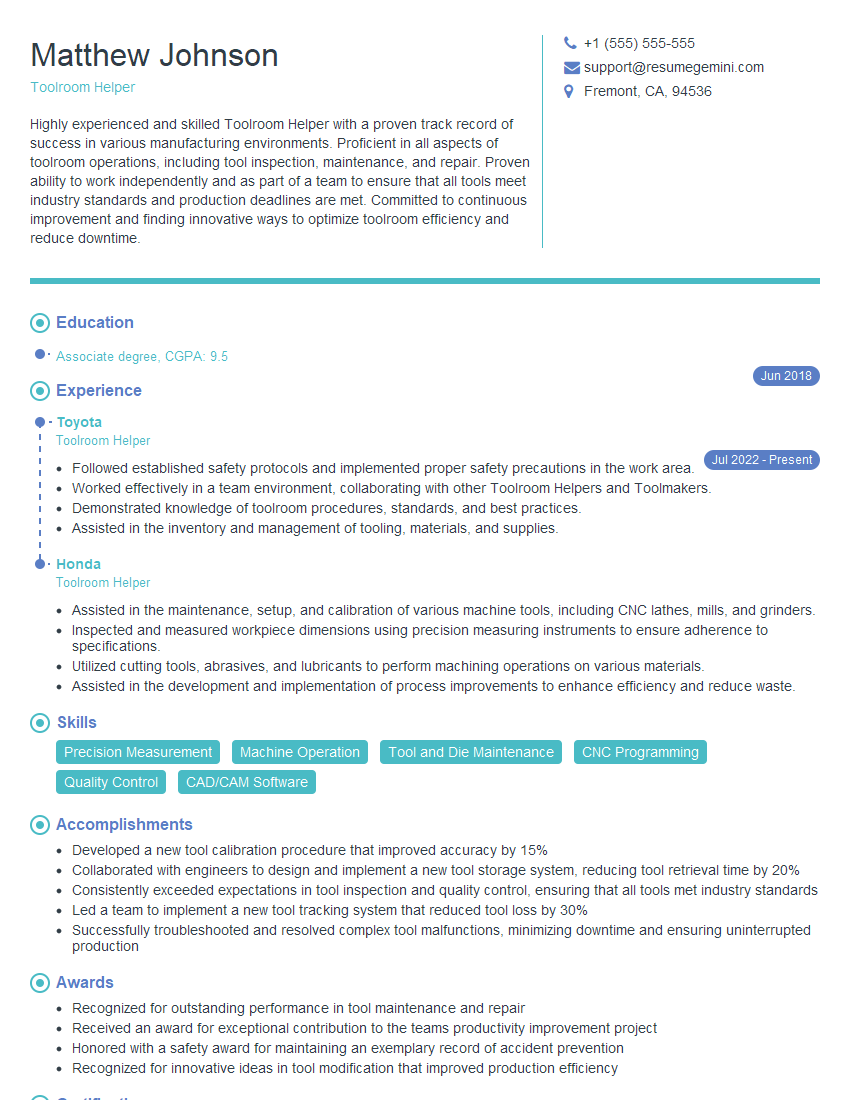

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toolroom Helper

1. Describe your experience in operating manual and automated machine tools.

- I have extensive experience in operating both manual and automated machine tools.

- I am proficient in using a variety of machines, including lathes, mills, grinders, and CNC machines.

- I have a strong understanding of machining principles and can set up and operate machines to produce high-quality parts.

2. Explain the steps involved in setting up a CNC machine to produce a specific part.

subheading of the answer

- The first step is to create a CAD drawing of the part.

- Once the CAD drawing is complete, it must be converted into a CNC program.

- The CNC program is then loaded into the machine.

- The machine is then set up with the appropriate tooling and materials.

- Finally, the machine is run and the part is produced.

subheading of the answer

- It is important to follow the manufacturer’s instructions carefully when setting up a CNC machine.

- Incorrectly setting up the machine can lead to damaged parts or even injury.

3. How do you maintain and troubleshoot CNC machines?

- Regular maintenance is important to keep CNC machines running smoothly.

- This includes tasks such as cleaning the machine, lubricating moving parts, and checking for loose connections.

- Troubleshooting is also an important skill for toolroom helpers.

- When a machine breaks down, it is important to be able to identify the problem and fix it quickly and efficiently.

4. What are the safety procedures that must be followed when working in a toolroom?

- There are a number of safety procedures that must be followed when working in a toolroom.

- These include wearing appropriate safety gear, keeping the work area clean and tidy, and following proper lockout/tagout procedures.

- It is also important to be aware of the hazards associated with the machines and materials being used.

5. What are the different types of cutting tools used in machining?

- There are a variety of different cutting tools used in machining.

- These include single-point cutting tools, such as lathe tools and milling cutters, and multi-point cutting tools, such as drills and taps.

- Each type of cutting tool is designed for a specific purpose.

- It is important to select the correct cutting tool for the job in order to achieve the desired results.

6. How do you measure and inspect machined parts?

- Machined parts must be inspected to ensure that they meet the required specifications.

- This can be done using a variety of measuring tools, such as calipers, micrometers, and coordinate measuring machines.

- It is important to have a good understanding of the inspection process in order to ensure that parts are inspected accurately.

7. What are the different types of materials that can be machined?

- A variety of different materials can be machined.

- These include metals, plastics, and composites.

- Each type of material has its own unique properties that must be taken into account when machining.

- It is important to select the correct machining process and cutting tools for the material being machined.

8. What are the different types of machining operations?

- There are a variety of different machining operations that can be performed.

- These include turning, milling, drilling, grinding, and shaping.

- Each type of machining operation is used to create a specific type of feature on a workpiece.

- It is important to select the correct machining operation for the job in order to achieve the desired results.

9. What are the different types of CNC machine tools?

- There are a variety of different types of CNC machine tools.

- These include lathes, mills, grinders, and EDM machines.

- Each type of CNC machine tool is designed for a specific type of machining operation.

- It is important to select the correct CNC machine tool for the job in order to achieve the desired results.

10. What are the different types of CAD/CAM software?

- There are a variety of different types of CAD/CAM software.

- These include software for 2D drawing, 3D modeling, and CNC programming.

- Each type of CAD/CAM software is designed for a specific purpose.

- It is important to select the correct CAD/CAM software for the job in order to achieve the desired results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toolroom Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toolroom Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Toolroom Helper is responsible for providing support to the Toolroom Supervisor and other Toolroom personnel. Key responsibilities include:

1. Tool Crib Management

Maintain the tool crib, including organizing and inventorying tools, issuing and receiving tools, and ensuring that tools are properly cleaned and maintained.

2. Tool Repair and Maintenance

Perform basic tool repair and maintenance tasks, such as sharpening cutting tools, replacing worn parts, and lubricating equipment.

3. Material Handling

Move materials, equipment, and tools within the toolroom and to other areas of the facility as needed.

4. Equipment Operation

Operate basic machine tools and equipment, such as lathes, mills, and grinders, under the supervision of the Toolroom Supervisor.

Interview Tips

To ace an interview for a Toolroom Helper position, candidates should be prepared to discuss their skills and experience in the following areas:

1. Toolroom Management

Candidates should highlight their experience in managing a tool crib, including organizing and inventorying tools, issuing and receiving tools, and ensuring that tools are properly cleaned and maintained.

2. Tool Repair and Maintenance

Candidates should demonstrate their ability to perform basic tool repair and maintenance tasks, such as sharpening cutting tools, replacing worn parts, and lubricating equipment.

3. Material Handling

Candidates should discuss their experience in moving materials, equipment, and tools within a toolroom and to other areas of a facility.

4. Equipment Operation

Candidates should highlight their experience in operating basic machine tools and equipment, such as lathes, mills, and grinders.

Next Step:

Now that you’re armed with the knowledge of Toolroom Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Toolroom Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini