Are you gearing up for an interview for a Track Oiler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Track Oiler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

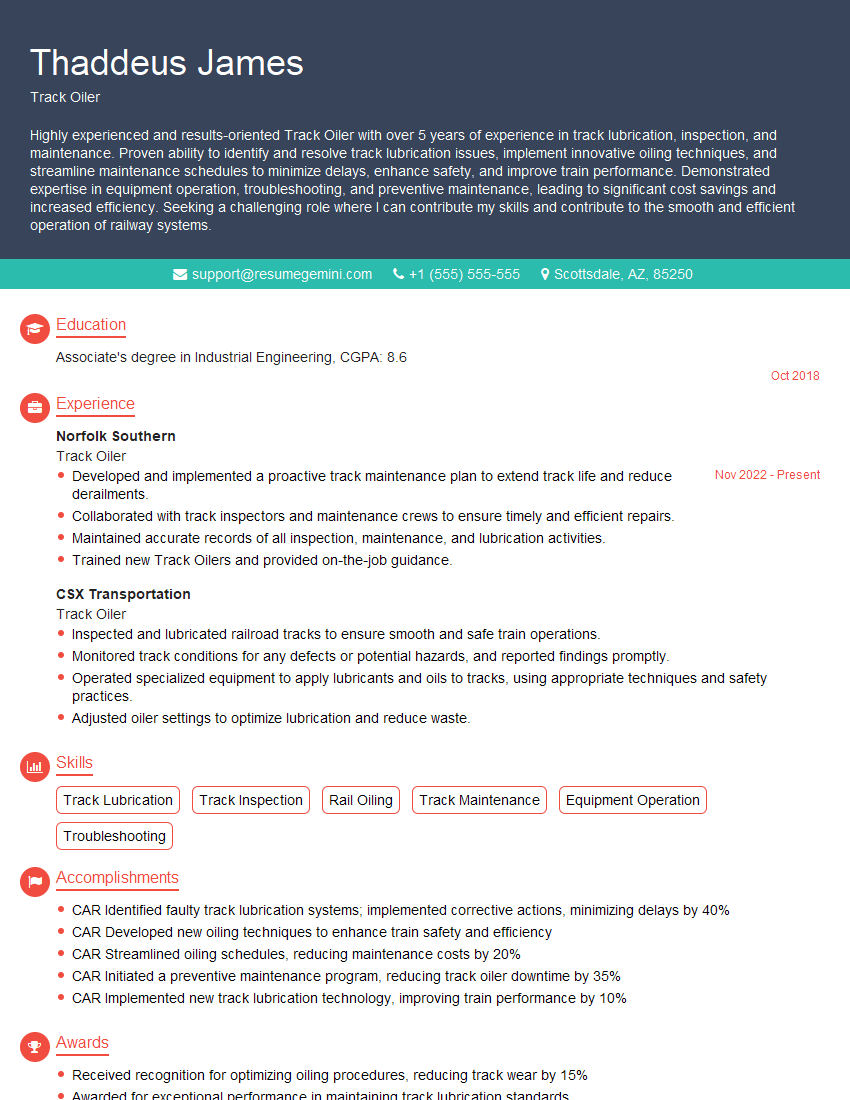

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Oiler

1. What are the main responsibilities of a Track Oiler?

As a Track Oiler, my primary responsibilities would include:

- Lubricating and oiling railroad tracks to reduce friction and wear

- Inspecting tracks for defects, such as cracks or loose bolts

- Monitoring oil levels in oil boxes and refilling them as needed

- Maintaining records of oil usage and track inspections

- Working with other track maintenance personnel to ensure the safe and efficient operation of trains

2. What are the safety precautions that must be taken when working as a Track Oiler?

Ensuring safety is paramount when working as a Track Oiler, which is why adherence to the following precautions is crucial:

- Always wear appropriate safety gear, including a hard hat, safety glasses, gloves, and protective footwear

- Be aware of your surroundings and stay clear of moving trains and other equipment

- Never work alone and always maintain a safe distance from other workers

- Follow all established safety procedures and report any unsafe conditions immediately

- Be familiar with emergency protocols and know how to respond in case of an accident

3. How would you identify and repair a loose track bolt?

Identifying a loose track bolt involves careful inspection of the track. Once identified, repairing it entails:

- Using a wrench to tighten the bolt to the proper torque specifications

- Replacing the bolt if it is damaged or excessively worn

- Inspecting neighboring bolts and tightening them if necessary to ensure overall track stability

- Reporting the repair to the appropriate supervisor for documentation

4. What types of oil are used to lubricate railroad tracks?

The type of oil used for railroad track lubrication depends on various factors. Common types include:

- Mineral oil: A petroleum-based oil that provides good lubrication and protection against wear

- Synthetic oil: A man-made oil that offers extended lubrication intervals and better performance in extreme temperatures

- Biodegradable oil: An environmentally friendly option made from plant-based materials, which is less harmful to the environment

- Graphite-based oil: A dry lubricant that reduces friction and is commonly used in dry climates

5. How do you determine the proper oil level in an oil box?

Determining the proper oil level in an oil box is crucial for effective lubrication. Here’s how:

- Locate the oil hole or sight glass on the oil box

- Insert a dipstick or use a flashlight to check the oil level

- The oil level should be between the indicated marks or within the visible range

- If the oil level is low, add oil until it reaches the proper level

- Overfilling the oil box should be avoided, as it can lead to oil leakage and other issues

6. What are the consequences of improper track lubrication?

Neglecting proper track lubrication can lead to severe consequences, including:

- Increased friction and wear on the track and train components

- Reduced train speed and efficiency due to increased rolling resistance

- Premature failure of track components, such as rails and fasteners

- Safety hazards, as improperly lubricated tracks can cause derailments or other accidents

- Increased maintenance costs due to the need for frequent repairs and replacements

7. How do you maintain accurate records of oil usage and track inspections?

Maintaining accurate records is essential for ensuring proper track maintenance. I would:

- Use a dedicated notebook or digital system to record all oil usage and track inspection data

- Document the date, location, type of oil used, and quantity added during each oiling

- Record the date, location, and any defects or issues identified during track inspections

- Keep these records organized and up-to-date for easy retrieval and analysis

- Submit regular reports to supervisors or other designated personnel as required

8. How would you handle a situation where you observe a track defect beyond your scope of repair?

If I encounter a track defect that exceeds my repair capabilities, I would:

- Immediately report the defect to my supervisor or the appropriate authority

- Provide a clear description of the defect, its location, and any potential safety hazards

- Secure the area if necessary to prevent trains from passing over the defective track

- Stay on-site until qualified personnel arrive to make repairs

- Assist with any necessary traffic control or safety measures as directed

9. What is the importance of teamwork in the role of a Track Oiler?

Teamwork is crucial for effective track maintenance. As a Track Oiler, I understand the importance of:

- Working collaboratively with other track maintenance personnel, such as track inspectors and repair crews

- Communicating effectively to ensure coordination and avoid misunderstandings

- Sharing knowledge and expertise to enhance overall team performance

- Supporting colleagues and providing assistance when needed

- Maintaining a positive and cooperative work environment

10. How do you stay updated on the latest industry best practices and regulations for track lubrication?

To stay current with industry best practices and regulations, I would:

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Participate in training programs offered by the company or industry organizations

- Network with other professionals in the field

- Seek guidance from experienced colleagues and supervisors

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The track oiler, an essential role in maintaining railway infrastructure, ensures smooth and efficient train operations. Their primary duty is to lubricate various track components to reduce friction and prevent wear, thereby guaranteeing the safe and reliable running of trains.

1. Lubrication Maintenance

The track oiler is responsible for:

- Applying oil to rail joints, switches, and crossings to minimize friction and wear.

- Inspecting and maintaining lubrication equipment, such as oil cans and pumps, ensuring their proper functioning.

- Monitoring track conditions, identifying areas in need of lubrication, and prioritizing maintenance accordingly.

2. Track Inspection

To ensure the safety and integrity of the railway track, the track oiler conducts regular inspections, looking for:

- Loose or missing rail fastenings, which can lead to track misalignment or derailments.

- Broken or cracked rails, which pose a significant safety hazard and require immediate attention.

- Damaged sleepers or ballast, which can compromise track stability and affect train performance.

3. Reporting and Communication

The track oiler plays a crucial role in maintaining open lines of communication within the railway maintenance team. They are responsible for:

- Reporting any track defects or maintenance issues to supervisors or engineers promptly.

- Documenting inspection findings and maintenance activities accurately and thoroughly.

- Participating in safety meetings and briefings to stay informed about track conditions and maintenance protocols.

4. Safety and Compliance

As a safety-sensitive position, the track oiler is expected to:

- Adhere to all railway safety regulations and guidelines.

- Wear appropriate personal protective equipment, including high-visibility clothing and safety glasses.

- Maintain a clean and organized work area, free from hazards that could cause accidents.

Interview Tips

Preparing for a track oiler interview requires a combination of technical knowledge and a strong understanding of railway maintenance practices. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the railway company and the rail industry in general. Learn about their safety record, maintenance standards, and any recent developments or challenges they have faced. This knowledge will demonstrate your interest and commitment to the field.

2. Highlight Your Technical Skills

Emphasize your technical abilities in track lubrication and inspection. Explain your understanding of rail joint types, lubrication methods, and the use of inspection tools. Provide specific examples of maintenance tasks you have performed and the results you achieved.

3. Demonstrate Safety Consciousness

Safety is paramount in the railway industry. In your interview, highlight your commitment to safety by discussing your knowledge of railway safety regulations, personal protective equipment requirements, and emergency protocols. Explain how you prioritize safety in your work and how you contribute to a safe work environment.

4. Show Your Physical Fitness

Track oilers are required to perform physically demanding tasks, such as carrying heavy equipment and working in various weather conditions. In the interview, be prepared to discuss your physical fitness and ability to handle the physical demands of the job.

5. Prepare Questions

At the end of the interview, it is common for interviewers to ask if you have any questions. Use this opportunity to demonstrate your interest and enthusiasm for the position. Prepare thoughtful questions about the company’s maintenance practices, safety protocols, and career advancement opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Track Oiler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!