Are you gearing up for a career in Woodworking Shop Hand? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Woodworking Shop Hand and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

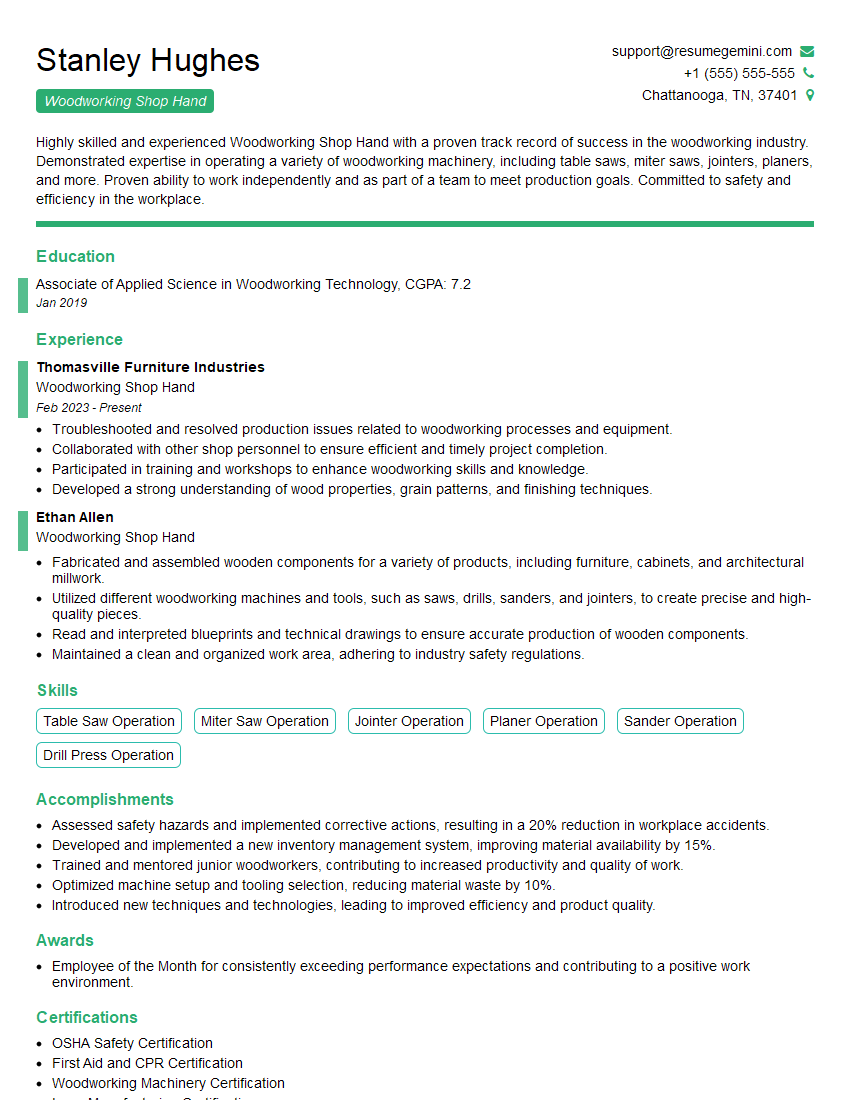

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Woodworking Shop Hand

1. Explain the process of creating a mortise and tenon joint?

Firstly, I would mark the location of the mortise on the workpiece. Then, I would use a chisel to cut out the mortise. Next, I would mark the location of the tenon on the other workpiece. Then, I would use a saw to cut out the tenon. Finally, I would assemble the joint by inserting the tenon into the mortise.

2. What are the different types of wood glue?

Water-based glue

- Pros: Easy to use, dries quickly, and is relatively inexpensive.

- Cons: Not as strong as other types of glue, and can be affected by moisture.

Solvent-based glue

- Pros: Strong and durable, and is not affected by moisture.

- Cons: Can be more difficult to use, takes longer to dry, and is more expensive than other types of glue.

Epoxy glue

- Pros: Extremely strong and durable, and is resistant to moisture.

- Cons: Can be more difficult to use, takes longer to dry, and is more expensive than other types of glue.

3. What are the different types of woodworking planes?

- Jack plane: A general-purpose plane that is used for smoothing and flattening surfaces.

- Jointer plane: A long plane that is used for straightening and flattening edges.

- Smoothing plane: A short plane that is used for smoothing and finishing surfaces.

- Block plane: A small plane that is used for trimming and shaping edges.

4. What are the different types of wood finishing techniques?

- Oiling: Oiling is a simple and effective way to protect and finish wood. Oils penetrate into the wood, providing a durable and water-resistant finish.

- Varnishing: Varnishes are clear finishes that provide a hard, glossy surface. Varnishes are more durable than oils, but they can be more difficult to apply.

- Shellac: Shellac is a natural finish that is made from the resin of the lac beetle. Shellac is a versatile finish that can be used on a variety of surfaces, including wood, metal, and glass.

- Lacquer: Lacquers are synthetic finishes that provide a hard, durable surface. Lacquers are easy to apply and dry quickly, but they can be more expensive than other types of finishes.

5. What are the different types of woodworking joints?

- Butt joint: A simple joint that is made by joining two pieces of wood together at their ends.

- Edge joint: A joint that is made by joining two pieces of wood together along their edges.

- Miter joint: A joint that is made by joining two pieces of wood together at an angle.

- Mortise and tenon joint: A joint that is made by joining two pieces of wood together by inserting a tenon (a protruding piece of wood) into a mortise (a hole).

- Dovetail joint: A strong and decorative joint that is made by interlocking two pieces of wood together.

6. What are the different types of woodworking tools?

- Hand tools: Hand tools are tools that are operated by hand, such as saws, hammers, and chisels.

- Power tools: Power tools are tools that are powered by electricity or air, such as drills, sanders, and table saws.

- Stationary tools: Stationary tools are tools that are mounted to a workbench or other surface, such as lathes, mills, and jointers.

7. What are the different types of woodworking materials?

- Hardwoods: Hardwoods are woods that come from deciduous trees, such as oak, maple, and cherry.

- Softwoods: Softwoods are woods that come from coniferous trees, such as pine, fir, and spruce.

- Engineered wood: Engineered wood is a type of wood that is made from wood fibers or particles that are glued together.

- Composite wood: Composite wood is a type of wood that is made from a mixture of wood fibers and other materials, such as plastic or rubber.

8. What are the different types of woodworking projects?

- Furniture: Furniture is a type of woodworking project that is used for sitting, sleeping, or storage.

- Cabinets: Cabinets are a type of woodworking project that is used for storage.

- Toys: Toys are a type of woodworking project that is made for children to play with.

- Tools: Tools are a type of woodworking project that is used for working with wood.

- Art: Art is a type of woodworking project that is made for decoration.

9. What are the different types of woodworking safety precautions?

- Wear appropriate safety gear, such as safety glasses, ear plugs, and a dust mask.

- Use sharp tools and keep them in good condition.

- Be aware of your surroundings and keep your work area clean and organized.

- Never operate power tools under the influence of alcohol or drugs.

- Always follow the manufacturer’s instructions for operating power tools.

10. What are the different types of woodworking techniques?

- Jointing: Jointing is a process of creating a flat and smooth surface on a piece of wood.

- Planing: Planing is a process of removing material from a piece of wood to create a smooth and flat surface.

- Sawing: Sawing is a process of cutting wood using a saw.

- Drilling: Drilling is a process of creating holes in wood using a drill.

- Sanding: Sanding is a process of smoothing the surface of wood using sandpaper.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Woodworking Shop Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Woodworking Shop Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Woodworking Shop Hands are responsible for assisting with the production of woodwork products in a factory or workshop setting. They work under the supervision of a lead worker or foreman and may perform a variety of tasks, including:

1. Machine Operation

Setting up and operating woodworking machines, such as saws, planers, and sanders.

- Ensuring that machines are properly calibrated and adjusted.

- Monitoring the quality of the finished product.

2. Material Handling

Loading and unloading materials from machines.

- Moving materials around the workshop.

- Maintaining a clean and organized work area.

3. Assembly

Assembling woodwork products, such as furniture, cabinets, and doors.

- Following assembly instructions.

- Using hand tools and power tools to join pieces together.

4. Finishing

Sanding, staining, and finishing woodwork products.

- Applying finishes to protect and enhance the appearance of the product.

- Inspecting finished products to ensure they meet quality standards.

Interview Tips

Preparing for an interview for a Woodworking Shop Hand position requires research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company and Position

Visit the company’s website to learn about their products, services, and company culture. Research the specific position you’re applying for, paying attention to the required skills and experience.

- Tailor your resume and cover letter to highlight relevant skills and experience.

- Prepare questions to ask the interviewer, demonstrating your interest and engagement.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice answering questions aloud, focusing on clearly articulating your skills, experience, and enthusiasm for woodworking.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples of your work.

- Emphasize your practical skills, such as machine operation, material handling, and assembly.

3. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview. Arrive on time, indicating your punctuality and respect for the interviewer’s schedule.

- Consider wearing comfortable, closed-toe shoes as you may be required to move around the workshop.

- Be polite and respectful to everyone you encounter during the interview process.

4. Be Enthusiastic and Ask Questions

Demonstrate your passion for woodworking and highlight your eagerness to learn and contribute to the team. Ask thoughtful questions that show your interest in the company and the position.

- Share examples of personal woodworking projects or hobbies that showcase your skills.

- Inquire about the company’s safety protocols and training opportunities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Woodworking Shop Hand, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Woodworking Shop Hand positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.