Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Adhesive Bandage Making Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Adhesive Bandage Making Operator so you can tailor your answers to impress potential employers.

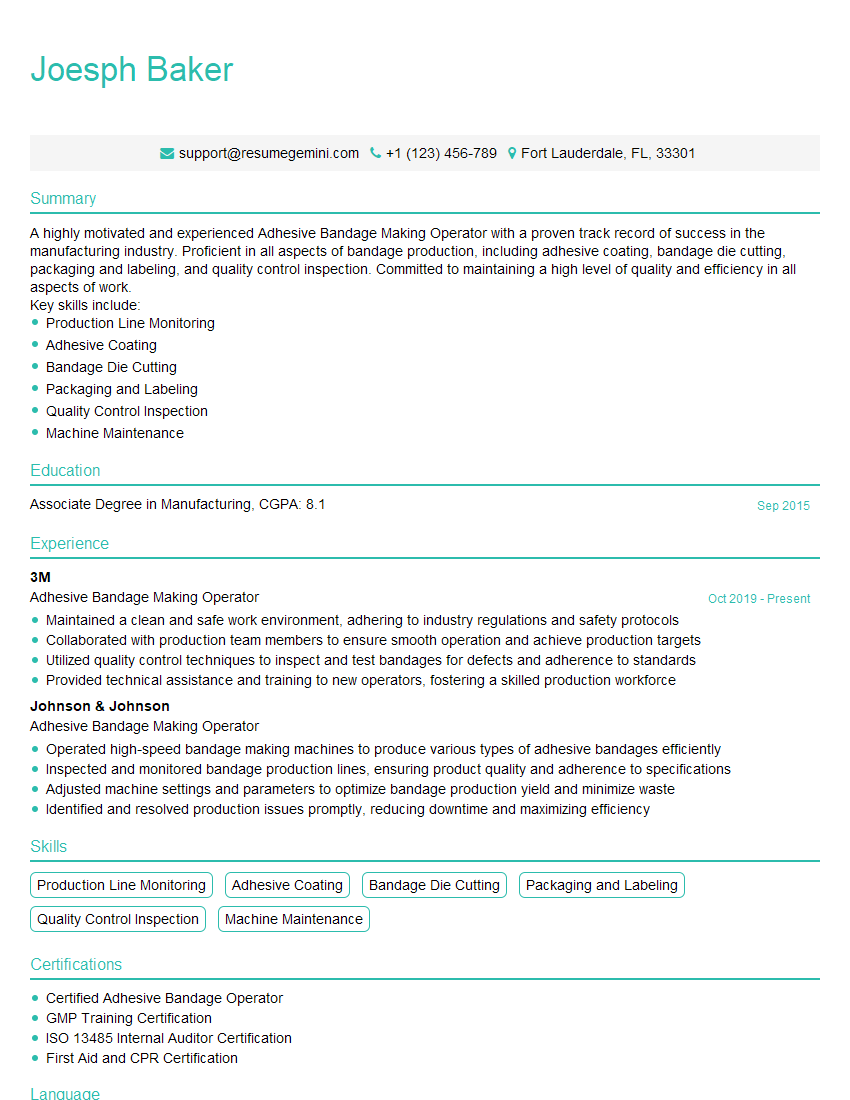

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Adhesive Bandage Making Operator

1. Describe the key steps involved in the adhesive bandage making process?

The key steps involved in adhesive bandage making process are:

- Web preparation: Unwinding the raw material, which is a non-woven fabric, and feeding it into the production line.

- Adhesive coating: Applying a layer of adhesive to the non-woven fabric using a coating machine.

- Pad application: Placing a pad, which is usually made of cotton or cellulose, onto the adhesive-coated fabric.

- Covering application: Covering the pad with a layer of non-woven fabric or a film to protect the wound.

- Cutting and packaging: Cutting the bandages into the required sizes and packaging them.

2. What are the different types of materials used in adhesive bandage production and their specific functions?

Non-woven fabric

- Provides the base material for the bandage.

- Absorbs exudate from the wound.

Adhesive

- Holds the bandage in place.

- Protects the wound from external contaminants.

Pad

- Absorbs blood and other fluids from the wound.

- Cushions the wound and protects it from pressure.

Covering

- Protects the wound from external contaminants.

- Prevents the bandage from sticking to the wound.

3. Explain the importance of quality control in adhesive bandage production?

Quality control is crucial in adhesive bandage production to ensure that the bandages meet the required standards of safety, effectiveness, and performance. It involves:

- Testing the raw materials to verify their quality.

- Monitoring the production process to ensure it meets specifications.

- Conducting regular inspections of the finished bandages to identify any defects.

- Implementing corrective actions to address any quality issues.

4. Describe the safety measures that should be followed when operating adhesive bandage making equipment?

When operating adhesive bandage making equipment, it is essential to follow safety measures to prevent accidents and injuries. These include:

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and a lab coat.

- Keeping the work area clean and free of tripping hazards.

- Following the manufacturer’s operating instructions for the equipment.

- Being aware of the potential hazards associated with the equipment, such as moving parts and electrical components.

- Reporting any accidents or injuries immediately to a supervisor.

5. Describe the troubleshooting steps you would take if the adhesive bandage machine is not dispensing bandages correctly?

If the adhesive bandage machine is not dispensing bandages correctly, I would perform the following troubleshooting steps:

- Check if the machine is properly set up and calibrated.

- Inspect the raw materials to ensure they are of good quality and meet specifications.

- Examine the machine for any mechanical issues, such as loose parts or worn components.

- Check the electrical connections and power supply.

- Review the machine’s operating manual or consult with a technician for further guidance.

6. Explain the importance of maintaining a clean and organized work environment in adhesive bandage production?

Maintaining a clean and organized work environment in adhesive bandage production is crucial for several reasons:

- Hygiene: It helps prevent contamination of the bandages with bacteria or other contaminants.

- Safety: A clean environment reduces the risk of accidents and injuries.

- Efficiency: A well-organized workspace allows for smooth operation and increased productivity.

- Quality: A clean environment contributes to the production of high-quality bandages.

7. Describe the different types of adhesive bandages and their specific applications?

- Regular adhesive bandages: Used for minor cuts and scrapes.

- Waterproof adhesive bandages: Used for wounds that may come into contact with water.

- Antibacterial adhesive bandages: Used for wounds that are at risk of infection.

- Breathable adhesive bandages: Used for wounds that require ventilation.

- Specialty adhesive bandages: Designed for specific body parts or wound types, such as finger bandages or blister bandages.

8. Explain the role of the adhesive bandage making operator in the overall production process?

The adhesive bandage making operator plays a vital role in the overall production process by:

- Setting up and operating the adhesive bandage making machine.

- Monitoring the production process to ensure it runs smoothly.

- Inspecting the finished bandages for quality.

- Maintaining the cleanliness and organization of the work area.

- Troubleshooting and resolving any issues that may arise during production.

9. Describe the importance of following standard operating procedures (SOPs) in adhesive bandage production?

Following SOPs in adhesive bandage production is essential for several reasons:

- Consistency: SOPs ensure that all operators follow the same procedures, resulting in consistent product quality.

- Safety: SOPs outline safe work practices to minimize the risk of accidents and injuries.

- Efficiency: SOPs streamline the production process, reducing waste and increasing productivity.

- Compliance: SOPs help ensure compliance with industry regulations and customer requirements.

- Training: SOPs serve as training tools for new operators and provide guidance for experienced operators.

10. Explain the different types of adhesive used in bandage production and their specific properties?

- Rubber-based adhesives: Strong and durable, but can be irritating to the skin.

- Acrylic adhesives: Hypoallergenic and gentle on the skin, but less durable than rubber-based adhesives.

- Silicone adhesives: Very soft and comfortable, but can be more expensive than other adhesives.

- Hydrocolloid adhesives: Absorbent and can help promote wound healing.

- Polyethylene adhesives: Breathable and waterproof, making them suitable for use on moist wounds.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Adhesive Bandage Making Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Adhesive Bandage Making Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Adhesive bandage making operators are responsible for the production of adhesive bandages. They operate a variety of machines to create the bandages, including die cutting machines, printing machines, and packaging machines. Operators also inspect the bandages for defects, package them, and ship them to customers.

1. Operate machinery

Adhesive bandage making operators use a variety of machines to create bandages, including die cutting machines, printing machines, and packaging machines. They must be able to operate these machines safely and efficiently.

- Die cutting machines cut the bandage material into the desired shape and size.

- Printing machines print the bandage with the desired design and information.

- Packaging machines package the bandages into individual units or boxes.

2. Inspect bandages

Adhesive bandage making operators must inspect the bandages for defects before packaging and shipping them. They must be able to identify and remove any defective bandages.

- Inspect the bandages for cuts, tears, or other damage.

- Inspect the bandages for proper printing and packaging.

- Remove any defective bandages from the production line.

3. Package and ship bandages

Adhesive bandage making operators package the bandages into individual units or boxes and ship them to customers. They must be able to package the bandages securely and efficiently.

- Package the bandages into individual units or boxes.

- Label the bandages with the appropriate information.

- Ship the bandages to customers.

4. Maintain a clean and safe work environment

Adhesive bandage making operators must maintain a clean and safe work environment. They must follow all safety procedures and regulations.

- Clean the work area regularly.

- Keep the equipment in good working order.

- Follow all safety procedures and regulations.

Interview Tips

To ace the interview for an adhesive bandage making operator position, there are a few things you can do to prepare.

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Why should we hire you?

Take some time to practice answering these questions in a clear and concise way.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Dress in clean, pressed clothing.

- Arrive on time for your interview.

- Be polite and respectful to everyone you meet.

4. Be enthusiastic and confident

Employers are looking for candidates who are enthusiastic and confident about their abilities. During the interview, be sure to convey your passion for the position and your confidence in your ability to do the job.

- Be prepared to talk about your skills and experience.

- Be confident in your abilities.

- Be positive and enthusiastic.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Adhesive Bandage Making Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.