Feeling lost in a sea of interview questions? Landed that dream interview for Automobile Carpets Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Automobile Carpets Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

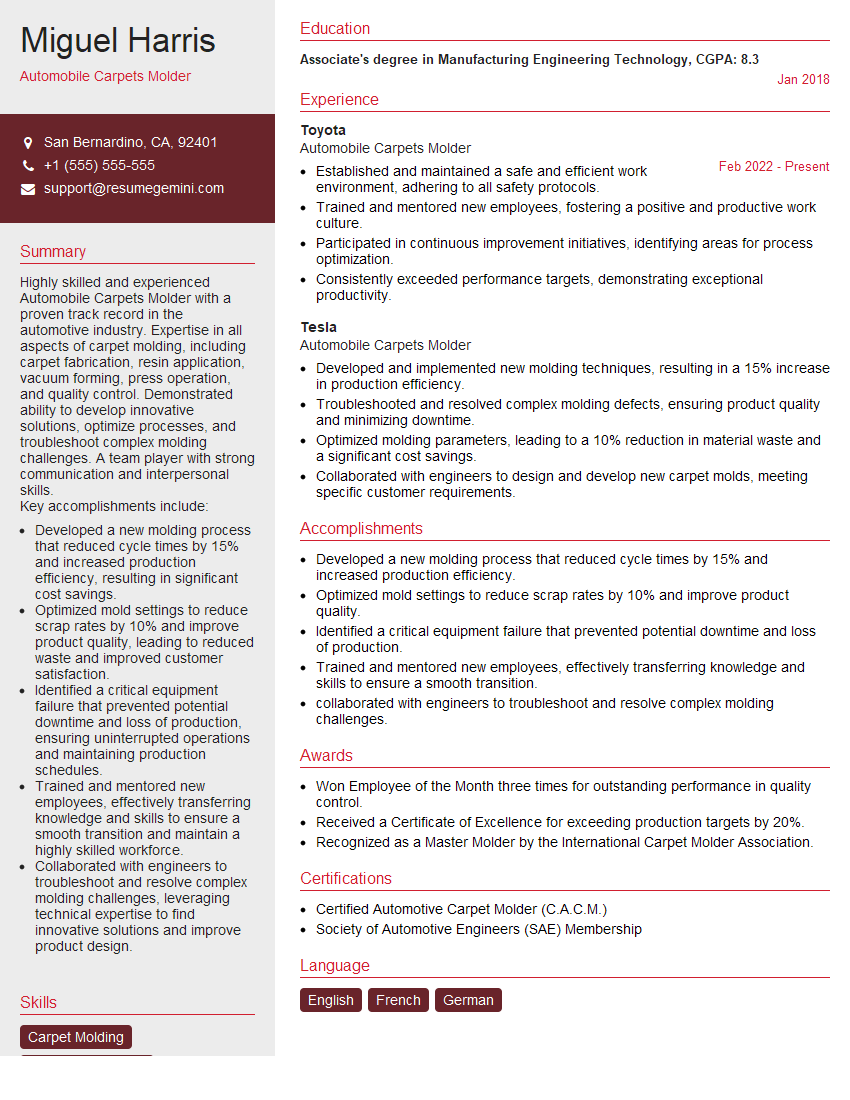

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automobile Carpets Molder

1. Describe the main responsibilities of an Automobile Carpets Molder?

As an Automobile Carpets Molder, my primary responsibilities encompass:

- Operating and maintaining molding machines to produce high-quality carpets for automobiles.

- Analyzing and interpreting carpet designs and specifications to ensure precise mold manufacturing.

- Selecting appropriate materials and adjusting molding parameters to optimize carpet quality and performance.

2. Explain the different types of molding techniques used in automobile carpet manufacturing?

Injection Molding

- Molten plastic is injected into a mold to create the desired shape.

- Suitable for producing complex and intricate carpet designs.

Compression Molding

- Pre-formed carpet material is placed in a mold and compressed to create the desired shape.

- Produces durable and wear-resistant carpets.

Thermoforming

- Plastic sheets are heated and molded over a form to create the desired shape.

- Allows for the production of large and flexible carpets.

3. How do you ensure the dimensional accuracy and quality of molded carpets?

To ensure dimensional accuracy and quality, I adhere to the following practices:

- Calibrating and maintaining molding machines regularly.

- Using high-quality materials and following standardized molding procedures.

- Inspecting carpets thoroughly at various stages of production to identify and rectify any defects.

- Working closely with design engineers to optimize mold designs for accuracy and efficiency.

4. Describe the importance of material selection in carpet molding?

Material selection plays a crucial role in determining the quality and performance of molded carpets. I consider the following factors:

- Fiber type and properties (e.g., nylon, polyester, polypropylene) to ensure durability, comfort, and stain resistance.

- Backing material (e.g., rubber, felt, jute) to provide stability, sound insulation, and moisture resistance.

- Additives and treatments (e.g., UV stabilizers, flame retardants) to enhance carpet performance and meet industry standards.

5. How do you troubleshoot and resolve common problems encountered during carpet molding?

To troubleshoot and resolve common molding problems effectively, I follow these steps:

- Identifying the specific issue (e.g., dimensional errors, surface imperfections, material defects).

- Analyzing machine settings, material properties, and environmental conditions to determine the root cause.

- Implementing corrective actions (e.g., adjusting pressures, temperatures, or material formulations).

- Monitoring the results and making further adjustments as necessary to ensure optimal carpet quality.

6. Explain the role of automation in modern carpet molding processes?

Automation plays a significant role in modern carpet molding by:

- Increasing production efficiency through automated machine operation and material handling.

- Reducing labor costs and improving productivity.

- Ensuring consistent and high-quality carpet production through precise and repeatable processes.

- Minimizing human error and improving safety in the manufacturing environment.

7. Describe the safety protocols and industry standards that you adhere to in your role?

Adhering to safety protocols and industry standards is paramount in my role. I strictly follow:

- Established safety procedures for operating molding machines and handling hazardous materials.

- Personal protective equipment (PPE) regulations to protect myself from potential risks.

- Industry best practices and quality control standards to ensure the production of safe and compliant carpets.

8. How do you stay updated with the latest advancements and technologies in carpet molding?

To stay updated with industry advancements and technologies, I actively engage in:

- Attending industry events, conferences, and workshops.

- Reading trade publications and technical journals.

- Participating in online forums and discussions.

- Seeking training opportunities to enhance my knowledge and skills.

9. How do you manage production schedules and meet deadlines in a fast-paced manufacturing environment?

To effectively manage production schedules and meet deadlines, I employ the following strategies:

- Planning and prioritizing tasks to ensure efficient use of resources.

- Monitoring production progress closely and identifying potential bottlenecks.

- Communicating effectively with colleagues and supervisors to coordinate activities.

- Implementing continuous improvement measures to streamline processes and reduce production times.

10. How do you contribute to the overall success and efficiency of your team?

As a team player, I contribute to the overall success and efficiency by:

- Sharing my knowledge and expertise with colleagues to enhance their performance.

- Providing support and assistance when needed, fostering a collaborative work environment.

- Identifying opportunities for improvement and implementing innovative solutions.

- Maintaining a positive and proactive attitude, motivating others to perform at their best.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automobile Carpets Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automobile Carpets Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automobile Carpets Molder is responsible for manufacturing and molding carpets for automobiles, ensuring they meet industry standards and client specifications.

1. Molding and Shaping

Mold carpets using various molding machines, extruding the raw material into the desired shape and size.

- Calibrate and adjust molding machines to achieve optimal performance

- Monitor molding processes to identify and correct any defects or inconsistencies

2. Material Handling

Handle and store raw materials and finished products as per established procedures and safety protocols.

- Unload and inspect incoming materials for quality and compliance

- Maintain inventory and ensure proper storage to prevent damage or contamination

3. Quality Control

Adhere to quality control standards and specifications to ensure the production of defect-free carpets.

- Inspect carpets for dimensional accuracy, surface finish, color uniformity, and other relevant parameters

- Conduct physical tests to evaluate the performance and durability of carpets

4. Equipment Maintenance

Perform routine maintenance on molding machines and other associated equipment to maintain optimal functionality.

- Clean, lubricate, and adjust machines to prevent breakdowns and ensure smooth operations

- Identify potential problems and take preventative measures to minimize downtime

Interview Tips

To ace an interview for an Automobile Carpets Molder position, preparation is key:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry standing, and the specific role you are applying for.

- Visit the company website and review their mission, values, and products/services

- Study the job description thoroughly to understand the core responsibilities and qualifications

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that align with the job requirements.

- Showcase your expertise in carpet molding and shaping techniques, as well as your knowledge of raw materials

- Provide examples of your quality control initiatives and how you maintained high production standards

3. Exhibit Problem-Solving Abilities

Interviewers are keen on candidates who can demonstrate their problem-solving capabilities.

- Describe situations where you identified and resolved issues in the molding process

- Explain how you troubleshoot equipment malfunctions and minimize production downtime

4. Be Prepared for Technical Questions

Expect technical questions about carpet molding equipment and processes.

- Review common molding techniques, such as compression molding, injection molding, and extrusion

- Understand the different types of carpeting materials and their properties

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automobile Carpets Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!