Feeling lost in a sea of interview questions? Landed that dream interview for Balancing Machine Set-Up Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Balancing Machine Set-Up Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

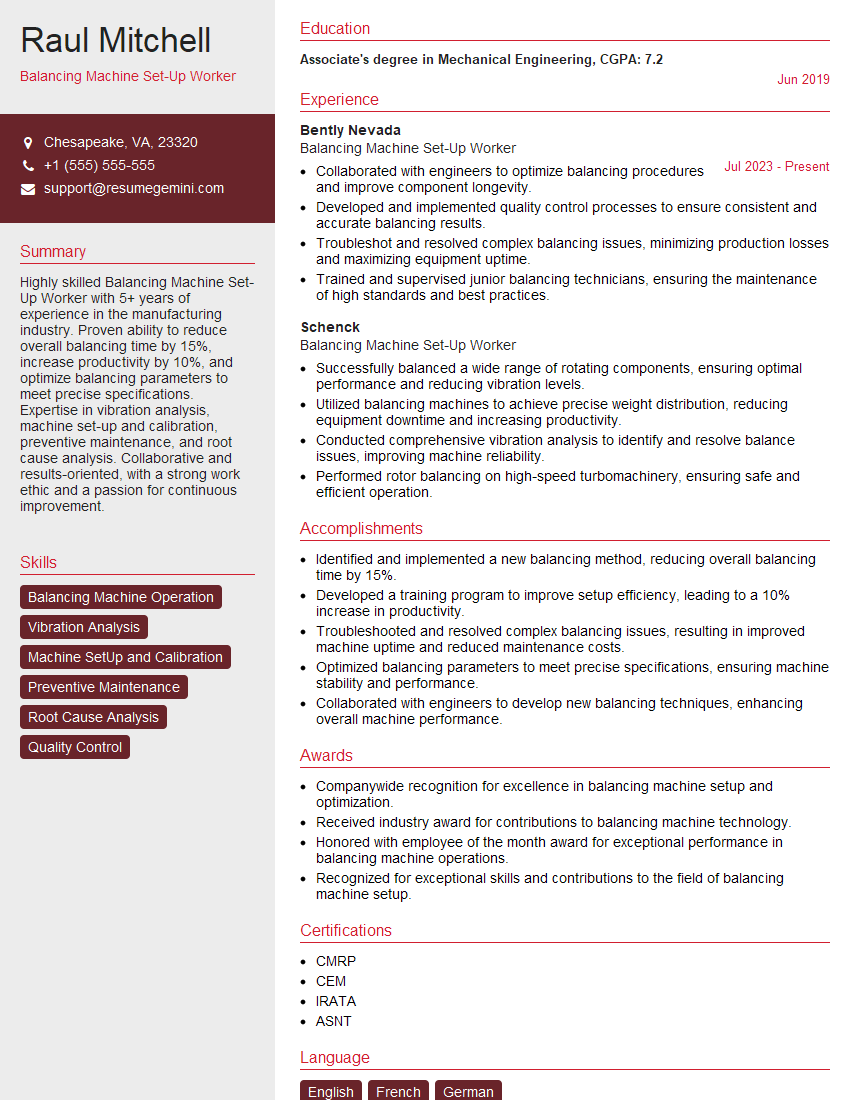

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Balancing Machine Set-Up Worker

1. How do you check the accuracy of a balancing machine?

To ensure the accuracy of a balancing machine, I follow these steps:

- Verify Calibration: I regularly calibrate the machine using known-good master parts or certified calibration equipment.

- Run Reference Parts: I run reference parts with known unbalance values to check machine response and accuracy.

- Compare Readings: I compare the machine’s readings with previous results or industry standards to detect any discrepancies.

- Monitor Performance: I monitor the machine’s performance over time, including any changes in readings or error messages, to identify potential accuracy issues.

2. What are the different balancing methods used in balancing machines?

Static Balancing

- Uses weights added to a plane to correct for unbalance in a single plane.

- Suitable for rotors with high rotational speeds or low unbalance.

Dynamic Balancing

- Corrects for unbalance in two planes.

- Balancing weights added to the rotor or shaft.

- Can handle higher unbalance levels than static balancing.

Modal Balancing

- More advanced method used for flexible rotors.

- Corrects for unbalance in multiple planes and modes of vibration.

- Requires specialized equipment and knowledge.

3. What are the common causes of unbalance in rotating machinery?

- Manufacturing defects

- Wear and tear

- Improper assembly

- Corrosion and erosion

- Misalignment

- Foreign objects

4. What is the role of vibration analysis in balancing?

Vibration analysis is used to:

- Detect and measure unbalance: By analyzing vibration patterns, the severity and location of unbalance can be identified.

- Monitor balancing results: Vibration analysis can verify the effectiveness of balancing and detect any residual unbalance.

- Identify other issues: Vibration analysis can also help identify other issues in rotating machinery, such as misalignment, bearing problems, or resonance.

5. What is the difference between mass balancing and moment balancing?

Mass balancing involves adding or removing mass from the rotor to correct for unbalance while moment balancing involves redistributing the mass along the rotor to correct for the unbalance moment.

6. How do you determine the optimal placement of balancing weights?

The optimal placement of balancing weights depends on:

- The rotor’s speed and unbalance characteristics

- The available space on the rotor

- Any constraints or limitations

I use calculations and software tools to determine the best placement based on these factors.

7. What are the safety precautions to consider when operating a balancing machine?

- Wear appropriate safety gear

- Ensure secure mounting of the rotor

- Use proper lifting techniques

- Follow manufacturer’s instructions

- Keep the work area clean and organized

- Be aware of moving parts

8. What types of machines can be balanced using balancing machines?

- Fans and blowers

- Pumps and compressors

- Turbines and generators

- Flywheels and crankshafts

- Driveshafts and propellers

9. How do you handle situations where balancing cannot be achieved?

If balancing cannot be achieved, I explore the following:

- Recheck the rotor: Ensure proper mounting, clean surfaces, and no damage.

- Verify machine accuracy: Calibrate the machine and check its performance with known standards.

- Consider residual unbalance: Determine if the remaining unbalance is acceptable based on industry standards or operational requirements.

- Consult with experts: Seek advice from more experienced engineers or manufacturers.

10. What are your goals as a Balancing Machine Set-Up Worker?

- To ensure the accuracy and effectiveness of balancing operations

- To contribute to the smooth and efficient operation of rotating machinery

- To stay up-to-date on industry best practices and technologies

- To work effectively as part of a team and meet production targets

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Balancing Machine Set-Up Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Balancing Machine Set-Up Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Balancing Machine Set-Up Worker is responsible for setting up and operating a balancing machine to achieve optimal operation of rotating equipment.

1. Machine Setup and Calibration

Prepares and sets up balancing machines, including installing bearings, couplings, and other components.

- Performs calibration and maintenance of balancing machines to ensure accuracy.

- Inspects and replaces worn or damaged parts as needed.

2. Equipment Balancing

Mounts and balances rotating equipment such as shafts, impellers, and flywheels on balancing machines.

- Adjusts weight distribution and position to minimize vibration and ensure smooth operation.

- Uses a variety of balancing techniques, including static and dynamic balancing.

3. Data Analysis and Reporting

Collects and analyzes data from the balancing process to evaluate equipment condition and identify any potential issues.

- Produces reports and documentation to summarize balancing results and provide recommendations.

- Collaborates with engineers and maintenance personnel to troubleshoot and resolve equipment issues.

4. Quality Control and Safety

Enforces quality control standards to ensure that balanced equipment meets specifications and operates safely.

- Inspects and tests equipment before and after balancing to verify accuracy.

- Follows safety protocols and maintains a clean and organized work area.

Interview Tips

Preparing for an interview for a Balancing Machine Set-Up Worker position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products or services, and industry trends.

- This demonstrates your interest in the company and shows that you’ve taken the initiative to learn about the industry.

- Mention specific projects or initiatives that align with your skills and interests.

2. Highlight Relevant Experience

Emphasize your experience setting up, calibrating, and operating balancing machines.

- Provide specific examples of your work and the results you achieved.

- Use numbers and metrics to quantify your impact.

3. Demonstrate Technical Skills

Be prepared to discuss the different balancing techniques and technologies you’re familiar with.

- Explain the principles of static and dynamic balancing and their applications.

- Discuss your experience using specific balancing instruments and software.

4. Communicate Effectively

Show that you have strong verbal and written communication skills.

- Prepare clear and concise answers to common interview questions.

- Be able to articulate your technical knowledge and findings in a way that is easy to understand.

5. Emphasize Safety and Attention to Detail

Highlight your commitment to safety and attention to detail.

- Describe your experience following safety protocols and maintaining a safe work environment.

- Explain how you ensure accuracy and quality in your work.

6. Ask Questions

Ask thoughtful questions about the position, the company, and the industry.

- This shows that you’re engaged and interested in learning more.

- Prepare a few questions beforehand and ask them at the end of the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Balancing Machine Set-Up Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!