Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ballpoint Pen Assembly Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ballpoint Pen Assembly Machine Operator so you can tailor your answers to impress potential employers.

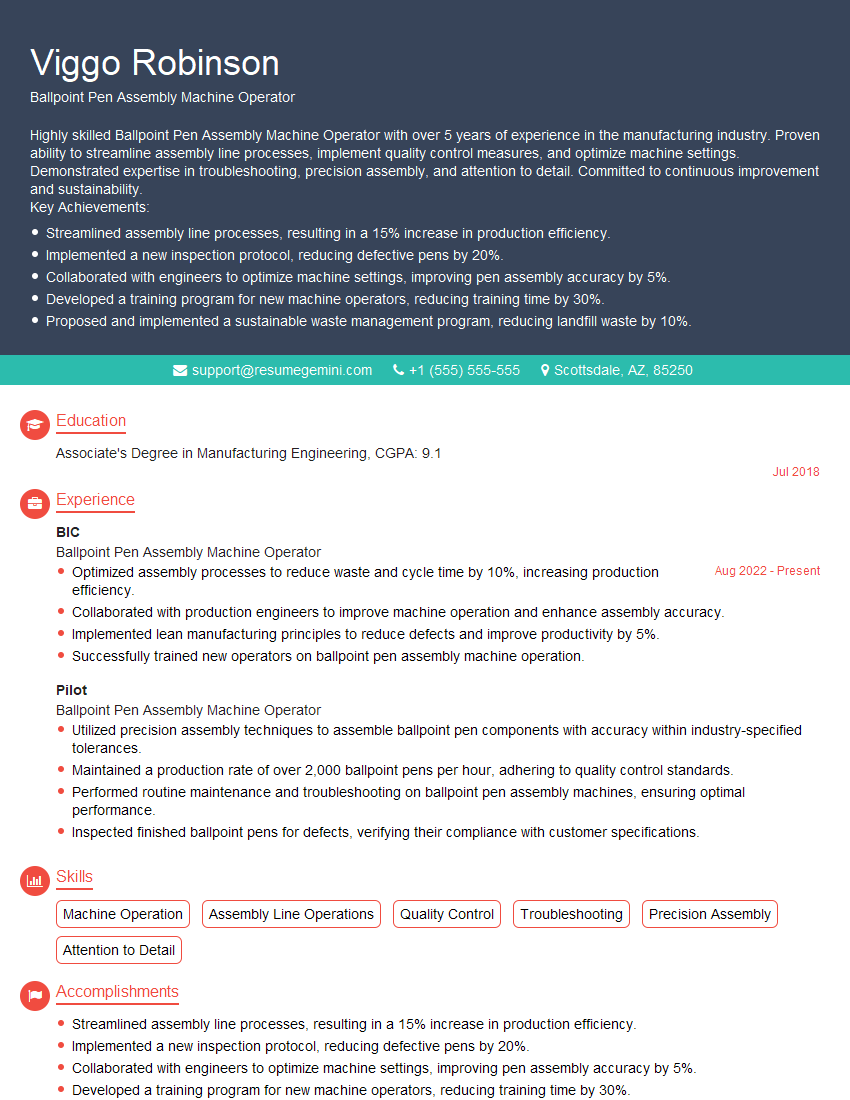

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ballpoint Pen Assembly Machine Operator

1. Explain the process of assembling a ballpoint pen using a machine.

The process of assembling a ballpoint pen using a machine generally involves the following steps:

- Load the machine with the necessary components, including the pen barrel, ink cartridge, tip, and spring.

- Align the components correctly within the machine’s assembly station.

- Activate the machine to assemble the pen components together, typically by pressing or inserting them into place.

- Inspect the assembled pen for any defects or malfunctions.

- Unload the finished pen from the machine and package it for distribution.

2. What are the key quality control checks you perform to ensure the pens meet specifications?

To ensure the pens meet specifications, I conduct the following key quality control checks:

- Visual Inspection: I visually check each assembled pen for any defects in the pen barrel, ink cartridge, tip, or spring.

- Dimensional Inspection: I use calipers or other measuring tools to ensure that the pen’s dimensions meet the required specifications.

- Ink Quality Check: I test the ink flow and consistency by writing with the pen and observing the smoothness and darkness of the writing.

- Functionality Check: I test the pen’s functionality by clicking the button or twisting the cap to ensure it operates smoothly and dispenses ink properly.

3. Describe the role of the spring in the ballpoint pen assembly.

In a ballpoint pen, the spring plays several vital roles:

- Retraction Mechanism: The spring provides the force to retract the tip back into the barrel when the pen is not in use.

- Ink Regulation: The spring exerts pressure on the ink cartridge, ensuring a consistent flow of ink to the tip.

- Shock Absorption: The spring absorbs shock and vibrations during writing, preventing damage to the pen’s components.

4. What actions do you take when the machine malfunctions?

When the assembly machine malfunctions, I follow these steps to address the issue:

- Identify the Malfunction: I observe the machine’s behavior and error messages to identify the source of the malfunction.

- Check for Obstructions: I inspect the machine for any foreign objects or debris that may be blocking its operation.

- Reset the Machine: If possible, I try resetting the machine by following the manufacturer’s instructions.

- Contact Maintenance: If I am unable to resolve the issue myself, I promptly contact the maintenance team for assistance.

- Record the Issue: I document the malfunction, including its symptoms and any steps I took to troubleshoot it, for future reference and preventive maintenance.

5. How do you handle repetitive tasks in your work?

I approach repetitive tasks in my work as follows:

- Focus and Accuracy: I maintain high levels of focus and accuracy throughout repetitive tasks to ensure consistent quality.

- Efficiency and Speed: While ensuring accuracy, I also strive to work efficiently and quickly to maximize productivity.

- Mindfulness and Breaks: I practice mindfulness to stay engaged and alert during repetitive tasks, and I take short breaks to maintain my focus and prevent fatigue.

- Continuous Improvement: I continuously seek ways to improve my techniques and optimize the repetitive tasks to enhance efficiency and reduce errors.

6. What is the importance of maintaining a clean and organized work area?

Maintaining a clean and organized work area is crucial for several reasons:

- Safety: It minimizes the risk of accidents and injuries by eliminating tripping hazards and clutter.

- Quality Control: It helps ensure the accuracy and consistency of pen assembly by preventing contamination or misplacement of components.

- Efficiency: An organized workspace allows for quick and easy access to necessary tools and materials, maximizing productivity.

- Professionalism: A clean and organized work area reflects a positive and professional image.

7. How do you handle working in a fast-paced and demanding environment?

To handle working in a fast-paced and demanding environment, I employ the following strategies:

- Time Management: I prioritize tasks and allocate my time effectively to meet deadlines.

- Adaptability: I am flexible and can quickly adjust to changing priorities and unexpected situations.

- Stress Management: I practice stress management techniques to stay calm and focused under pressure.

- Communication: I communicate clearly and effectively with colleagues and supervisors to ensure smooth coordination.

- Continuous Improvement: I constantly seek feedback and identify ways to optimize my work processes and enhance efficiency.

8. What is your understanding of the industry standards for ballpoint pen assembly?

My understanding of the industry standards for ballpoint pen assembly includes adherence to the following:

- Dimensional Specifications: Ensuring that the pens meet the specified dimensions and tolerances.

- Material Quality: Using materials that meet the required standards for durability, functionality, and aesthetics.

- Ink Performance: Meeting the standards for ink flow, consistency, and writing quality.

- Safety Standards: Complying with safety regulations and guidelines to prevent hazards and injuries.

- Environmental Regulations: Adhering to environmental regulations related to the materials and processes used in pen assembly.

9. How do you stay updated with the latest advancements in ballpoint pen assembly technology?

To stay updated with the latest advancements in ballpoint pen assembly technology, I engage in the following practices:

- Industry Publications: I read industry publications and articles to gain insights into new technologies and best practices.

- Webinars and Conferences: I attend webinars and conferences to learn about innovative techniques and advancements.

- Manufacturer Updates: I keep myself informed about product updates and improvements from pen assembly machine manufacturers.

- Networking: I connect with peers and experts in the field to share knowledge and stay abreast of industry trends.

- Continuous Learning: I am always open to learning new skills and exploring new technologies to enhance my proficiency.

10. Why are you interested in this Ballpoint Pen Assembly Machine Operator position?

I am highly interested in this Ballpoint Pen Assembly Machine Operator position because it aligns with my skills, experience, and career aspirations. I am confident that my technical expertise, attention to detail, and commitment to quality will make me a valuable asset to your team.

Furthermore, I am eager to contribute my knowledge and skills to the production of high-quality ballpoint pens. I am particularly interested in the opportunity to learn from experienced professionals and contribute to the optimization of the assembly process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ballpoint Pen Assembly Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ballpoint Pen Assembly Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Ballpoint Pen Assembly Machine Operator operates and maintains a machine that assembles ballpoint pens. Key job responsibilities include:

1. Machine Operation

Ensuring the smooth and efficient operation of the ballpoint pen assembly machine, including loading raw materials, setting up and adjusting machine parameters, and monitoring the assembly process.

- Loading raw materials such as pen barrels, ink cartridges, and tips into the machine.

- Setting up and adjusting machine parameters such as speed, temperature, and pressure to optimize production.

- Monitoring the assembly process and making necessary adjustments to ensure quality standards are met.

- Troubleshooting and resolving any machine malfunctions or production issues promptly to minimize downtime.

2. Quality Control

Ensuring the quality and accuracy of the assembled ballpoint pens, including inspecting pens for defects, and making adjustments as needed.

- Inspecting pens for defects such as missing or misaligned parts, ink leakage, or uneven finishes.

- Making necessary adjustments to the machine or assembly process to correct defects and improve quality.

- Maintaining quality records and reporting any quality issues to supervisors.

3. Production Optimization

Optimizing the production process to increase efficiency, reduce waste, and meet production targets.

- Identifying and implementing process improvements to reduce assembly time and increase output.

- Minimizing waste by reducing material usage and optimizing machine settings.

- Meeting production targets by ensuring the machine operates at optimal efficiency and quality standards are maintained.

4. Safety and Maintenance

Ensuring a safe and clean work environment, including following safety protocols, and performing routine maintenance on the machine.

- Following established safety protocols, wearing appropriate protective gear, and maintaining a clean work area.

- Performing routine maintenance on the machine, including lubrication, cleaning, and minor repairs.

- Reporting any safety hazards or maintenance issues to supervisors promptly.

Interview Preparation Tips

To ace the interview for a Ballpoint Pen Assembly Machine Operator position, consider the following tips:

1. Research the Company and Role

Research the company’s history, products, and industry reputation to understand their business and culture. Familiarize yourself with the specific role and its responsibilities to demonstrate your understanding of the position.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Practice your answers to ensure they are concise, relevant, and highlight your qualifications.

3. Quantify Your Accomplishments

When describing your experience, focus on quantifiable accomplishments and results. Use specific numbers, metrics, or examples to demonstrate the impact of your contributions in previous roles.

4. Highlight Relevant Skills and Experience

Emphasize skills and experience that are directly relevant to the job requirements. For example, highlight your ability to operate and maintain similar machinery, your attention to detail, and your commitment to quality.

5. Demonstrate Your Problem-Solving Abilities

Provide examples of how you have solved problems or overcome challenges in your previous roles. This will demonstrate your ability to think critically, make decisions, and implement effective solutions.

6. Be Enthusiastic and Professional

Show enthusiasm for the role and the company during the interview. Dress professionally, arrive on time, and maintain a positive and confident demeanor throughout the interview process.

7. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer about the company, the role, or the industry. Asking informed questions demonstrates your interest, curiosity, and engagement in the interview.

Next Step:

Now that you’re armed with the knowledge of Ballpoint Pen Assembly Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ballpoint Pen Assembly Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini