Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bar and Filler Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bar and Filler Assembler so you can tailor your answers to impress potential employers.

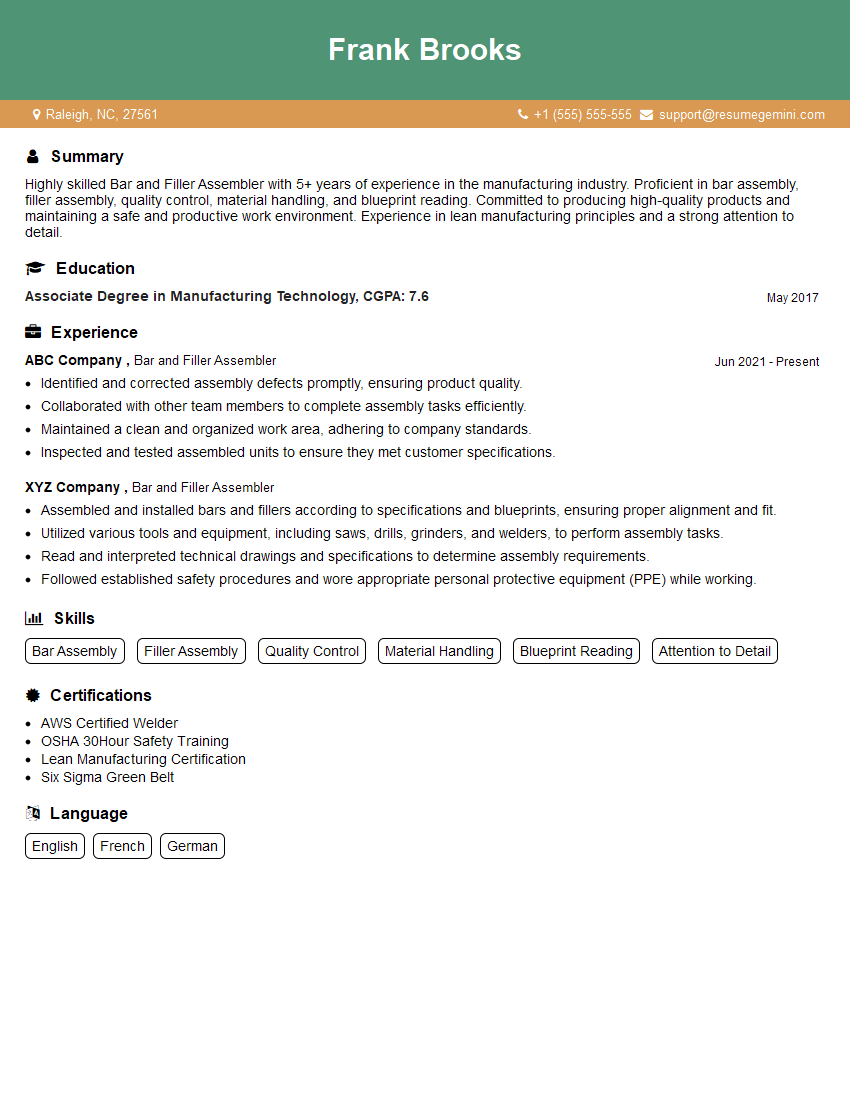

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bar and Filler Assembler

1. Describe the process of assembling bars and fillers?

The process of assembling bars and fillers involves several key steps:

- Preparation: Gather the necessary materials, including bars, fillers, and fasteners.

- Bar cutting: Cut the bars to the desired lengths using a metal-cutting saw or other appropriate tool.

- Filler placement: Place the fillers between the bars to achieve the desired spacing and support.

- Assembling: Join the bars and fillers together using welding, riveting, or other appropriate fastening techniques.

- Inspection and finishing: Inspect the assembled frame for any defects or imperfections. Clean and finish the frame as necessary.

2. What types of materials are commonly used in bar and filler assemblies?

Metals

- Steel (stainless, carbon, etc.)

- Aluminum

- Brass

Plastics

- Polypropylene (PP)

- High-density polyethylene (HDPE)

- Polyvinyl chloride (PVC)

Other Materials

- Wood

- Composite materials

3. What types of joining techniques are used for bar and filler assemblies?

- Welding: Fuses metals together using heat and pressure.

- Riveting: Inserts a metal pin through holes in the bars and fillers to hold them together.

- Bolting: Uses bolts and nuts to mechanically fasten the components.

- Adhesives: Bonds materials together using chemical bonding agents.

4. How do you ensure the accuracy and precision of bar and filler assemblies?

- Precise measurements: Use calibrated measuring tools to ensure accurate dimensions.

- Proper alignment: Align the bars and fillers carefully before joining to prevent any misalignment.

- Use of jigs and fixtures: Utilize specialized tools to hold the components in place and ensure uniformity.

- Quality control: Regularly inspect the assemblies to identify and correct any deviations from specifications.

5. How do you troubleshoot problems that may arise during bar and filler assembly?

Troubleshooting problems involves:

- Identifying the issue: Determine the cause of the problem by observing the symptoms and inspecting the assembly.

- Checking measurements: Verify the dimensions and alignment of the components to ensure they meet specifications.

- Inspecting connections: Examine welds, rivets, or bolts to ensure they are secure and free from defects.

- Reviewing assembly procedures: Ensure that the assembly process was followed correctly and that no steps were missed.

6. How do you work in a team setting to complete bar and filler assemblies efficiently?

- Communication: Communicate effectively with team members to ensure everyone understands the tasks and requirements.

- Coordination: Collaborate with others to coordinate workflow and prevent any delays or bottlenecks.

- Support: Provide support to team members by assisting with tasks and sharing knowledge.

- Accountability: Take ownership of assigned tasks and ensure they are completed to the required standards.

7. What safety precautions do you take when working with bars and fillers?

- Wear proper attire: Wear appropriate protective clothing, including gloves, safety glasses, and sturdy footwear.

- Use sharp tools with care: Handle cutting tools safely to prevent injuries.

- Maintain a clean work area: Keep the workspace organized and free from tripping hazards or obstructions.

- Follow established safety procedures: Adhere to company safety policies and guidelines.

8. How do you stay up to date on the latest techniques and materials used in bar and filler assembly?

- Industry conferences and trade shows: Attend events to learn about new technologies and products.

- Online resources and webinars: Utilize online platforms to access information and participate in training sessions.

- Trade magazines and technical publications: Stay informed by reading industry-specific publications.

- Manufacturer training: Attend training programs offered by material or equipment manufacturers.

9. What are some of the challenges you have faced as a Bar and Filler Assembler and how did you overcome them?

Provide specific examples of challenges encountered and describe the steps taken to resolve them:

- Example Challenge: Ensuring accuracy in complex assemblies.

- Solution: Implemented a rigorous quality control process, using precision measuring tools and inspection equipment.

10. Describe a time when you had to meet a tight deadline for a bar and filler assembly project. How did you manage your time and ensure the quality of the work?

Provide a detailed account of the project and the strategies used to meet the deadline:

- Project Details: Describe the specific requirements and challenges of the project.

- Time Management Strategies: Explain how you prioritized tasks, allocated resources, and managed workflow.

- Quality Control Measures: Describe the steps taken to maintain quality standards while working under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bar and Filler Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bar and Filler Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bar and Filler Assemblers hold a crucial role in the construction industry, ensuring the safe and precise assembly of structural frameworks. Their responsibilities encompass a wide range of tasks:

1. Bar Assembly

Fabricate and assemble reinforcement steel bars according to blueprints and specifications.

- Cut, bend, and weld steel bars to create rebar cages, stirrups, and other structural components.

- Assemble and secure reinforcing steel into forms or structures using welding, wire ties, or other fasteners.

2. Filler Assembly

Prepare and install fillers and spacers to maintain proper spacing and alignment of reinforcement bars.

- Place, align, and secure fillers and spacers between steel bars to ensure the correct concrete coverage and spacing.

- Use various tools and techniques to cut, shape, and attach fillers and spacers to the reinforcement bars.

3. Inspection and Quality Control

Inspect assembled reinforcement structures for accuracy, compliance with specifications, and structural integrity.

- Check measurements, alignments, and connections to ensure adherence to blueprints and safety standards.

- Identify and rectify any defects or discrepancies in the assembled reinforcement.

4. Material Handling and Safety

Handle heavy steel materials and operate equipment safely and efficiently.

- Properly load, unload, and transport steel materials and equipment.

- Follow safety protocols and wear appropriate protective gear while operating machinery and working with steel.

Interview Tips

To ace the interview for a Bar and Filler Assembler position, it’s essential to prepare thoroughly and demonstrate your skills and knowledge effectively. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific job responsibilities. This will enable you to answer questions confidently and show your enthusiasm for the role.

- Visit the company’s website to learn about its values, mission, and current projects.

- Review the job description carefully and note the key requirements and qualifications.

2. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job description. Provide specific examples to demonstrate your proficiency in bar assembly, filler assembly, and quality control.

- Showcase your ability to read and interpret blueprints and specifications.

- Describe your experience using welding equipment, wire ties, and other tools.

- Share examples of successful projects where you ensured the accuracy and quality of assembled reinforcement structures.

3. Emphasize Safety and Attention to Detail

Safety and attention to detail are paramount in this role. Highlight your commitment to safety protocols and your meticulous approach to ensuring that assembled structures meet specifications.

- Explain your understanding of safety regulations and your experience following them strictly.

- Provide examples of how you prioritize accuracy and precision in your work.

4. Be Enthusiastic and Ask Questions

Show your enthusiasm for the opportunity and the construction industry. Ask thoughtful questions to demonstrate your interest in the company and the role.

- Inquire about the company’s recent projects and their plans for the future.

- Ask about opportunities for professional development and growth within the organization.

5. Practice and Prepare

Practice answering common interview questions and prepare a brief summary of your skills and experience. This will help you feel confident and organized during the interview.

- Prepare to discuss your experience in bar and filler assembly and your commitment to safety.

- Practice answering questions about your strengths and weaknesses, and be ready to provide specific examples.

Next Step:

Now that you’re armed with the knowledge of Bar and Filler Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bar and Filler Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini