Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bearing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

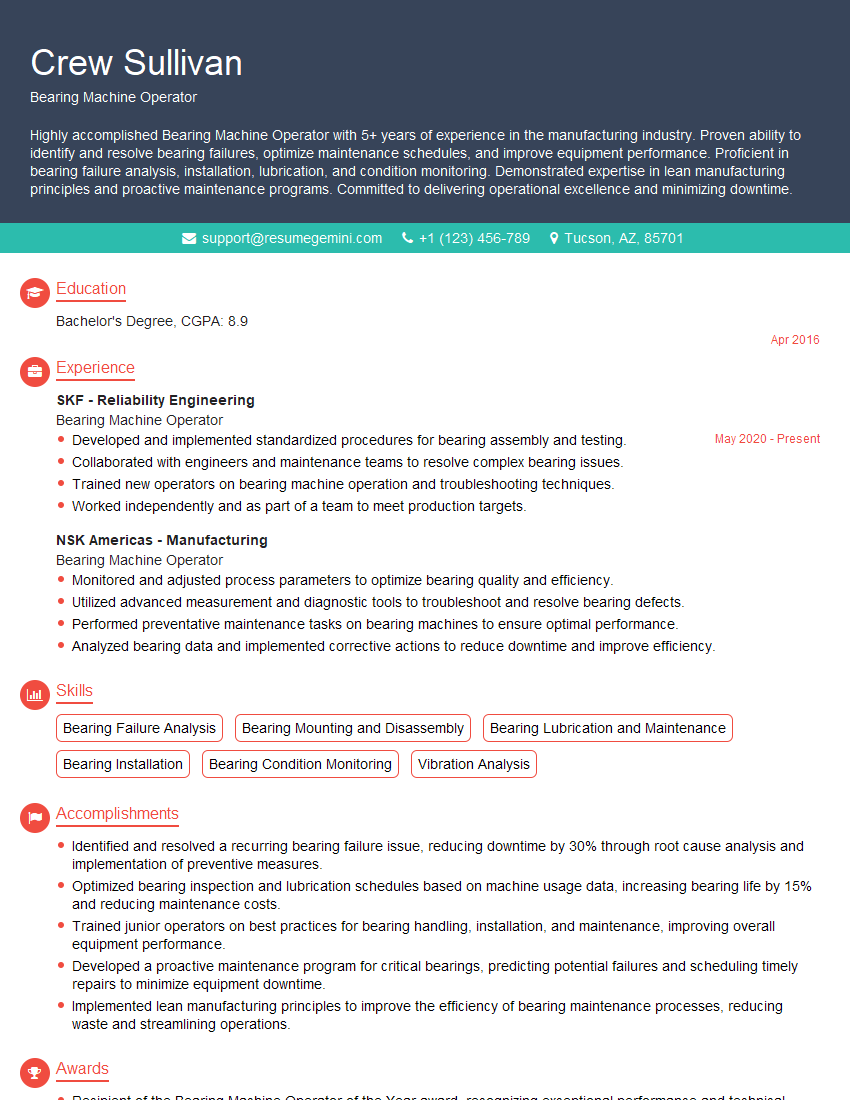

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bearing Machine Operator

1. What is the difference between a radial bearing and a thrust bearing?

- Radial bearings are designed to support radial loads, which are forces that act perpendicular to the shaft axis.

- Thrust bearings are designed to support thrust loads, which are forces that act parallel to the shaft axis.

2. What are the different types of radial bearings?

Ball bearings

- Ball bearings are the most common type of radial bearing.

- They consist of a set of balls that are held between an inner and outer race.

- Ball bearings are relatively inexpensive and can handle both radial and axial loads.

Roller bearings

- Roller bearings are another common type of radial bearing.

- They consist of a set of rollers that are held between an inner and outer race.

- Roller bearings are more expensive than ball bearings, but they can handle higher loads.

Tapered roller bearings

- Tapered roller bearings are a type of radial bearing that is designed to handle high thrust loads.

- They consist of a set of tapered rollers that are held between an inner and outer race.

- Tapered roller bearings are more expensive than ball bearings and roller bearings, but they can handle the highest loads.

3. What are the different types of thrust bearings?

Collar thrust bearings

- Collar thrust bearings are the most common type of thrust bearing.

- They consist of a collar that is held between two thrust washers.

- Collar thrust bearings are relatively inexpensive and can handle both radial and axial loads.

Tapered roller thrust bearings

- Tapered roller thrust bearings are a type of thrust bearing that is designed to handle high thrust loads.

- They consist of a set of tapered rollers that are held between an inner and outer race.

- Tapered roller thrust bearings are more expensive than collar thrust bearings, but they can handle higher loads.

Angular contact thrust bearings

- Angular contact thrust bearings are a type of thrust bearing that is designed to handle high thrust loads and moderate radial loads.

- They consist of a set of ball bearings that are held between an inner and outer race.

- Angular contact thrust bearings are more expensive than collar thrust bearings and tapered roller thrust bearings, but they can handle the highest loads.

4. What are the different factors that affect the selection of a bearing?

- Load capacity

- Speed

- Temperature

- Lubrication

- Environment

5. What are the different types of bearing failures?

- Fatigue failure

- Wear failure

- Corrosion failure

- Contamination failure

- Lubrication failure

6. What are the different methods of bearing maintenance?

- Lubrication

- Inspection

- Replacement

7. How do you measure the clearance of a bearing?

- Use a dial indicator to measure the distance between the inner and outer races.

- Place the dial indicator on the inner race and zero it out.

- Push the outer race towards the inner race until it contacts the dial indicator.

- Read the dial indicator to determine the clearance.

8. How do you adjust the preload of a bearing?

- Use a spanner wrench to tighten the locknut on the bearing.

- Turn the locknut until the desired preload is achieved.

- Check the preload using a dial indicator.

9. How do you troubleshoot a bearing problem?

- Listen for unusual noises.

- Check for vibration.

- Inspect the bearing for wear and damage.

- Check the lubrication.

- Check the clearance and preload.

10. What are the latest trends in bearing technology?

- The use of new materials, such as ceramic and plastic.

- The development of new bearing designs, such as the hybrid bearing.

- The use of new manufacturing techniques, such as 3D printing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bearing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bearing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Bearing Machine Operator is responsible for operating and maintaining bearing machines in order to manufacture bearings. This involves working with a variety of equipment, including lathes and grinders, to precise specifications.

1. Setup and operate bearing machines

The operator will typically start by setting up the bearing machine according to the specifications of the bearing that is to be manufactured. This involves setting up the tooling and the machine’s speed and feed rates.

- Operates bearing machines to manufacture bearings

- Sets up and maintains bearing machines

- Monitors bearing machine performance

2. Inspect bearings

The operator will then inspect the bearing to ensure that it meets the required specifications. This involves checking the bearing’s dimensions, surface finish, and other characteristics.

- Inspects bearings for defects

- Ensures that bearings meet specifications

- Rejects bearings that do not meet specifications

3. Troubleshoot bearing issues

If a bearing does not meet the required specifications, the operator will need to troubleshoot the issue. This involves identifying the root cause of the problem and taking corrective action.

- Troubleshoots bearing issues

- Repairs bearing machines

- Maintains bearing inventory

4. Maintain bearing machines

The operator will also be responsible for maintaining the bearing machines. This involves cleaning and lubricating the machines, as well as replacing worn parts.

- Maintains bearing machines

- Cleans and lubricates bearing machines

- Replaces worn parts

Interview Tips

Here are some tips to help you ace your interview for a Bearing Machine Operator position:

1. Research the company and the position

It is important to research the company and the position you are applying for before your interview. This will help you to understand the company’s culture, values, and goals. It will also help you to understand the specific requirements of the position and what the company is looking for in a candidate.

- Visit the company’s website

- Read the job description carefully

- Talk to people in your network who work for the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you can expect to be asked. It is important to practice your answers to these questions in advance so that you can deliver them confidently and clearly. Some common interview questions include:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “What is your experience with bearing machines?”

- “How do you troubleshoot bearing issues?”

3. Be prepared to talk about your experience

The interviewer will likely ask you about your experience in operating and maintaining bearing machines. Be prepared to talk about your specific skills and experience, and how they relate to the requirements of the position.

- Highlight your experience with similar equipment

- Quantify your accomplishments with specific examples

- Be prepared to discuss your troubleshooting skills

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the position and who is confident in their abilities. Be sure to convey your enthusiasm during the interview, and be positive about your skills and experience.

- Smile and make eye contact

- Speak clearly and confidently

- Be positive and enthusiastic about the position

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bearing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.