Feeling lost in a sea of interview questions? Landed that dream interview for Block Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Block Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

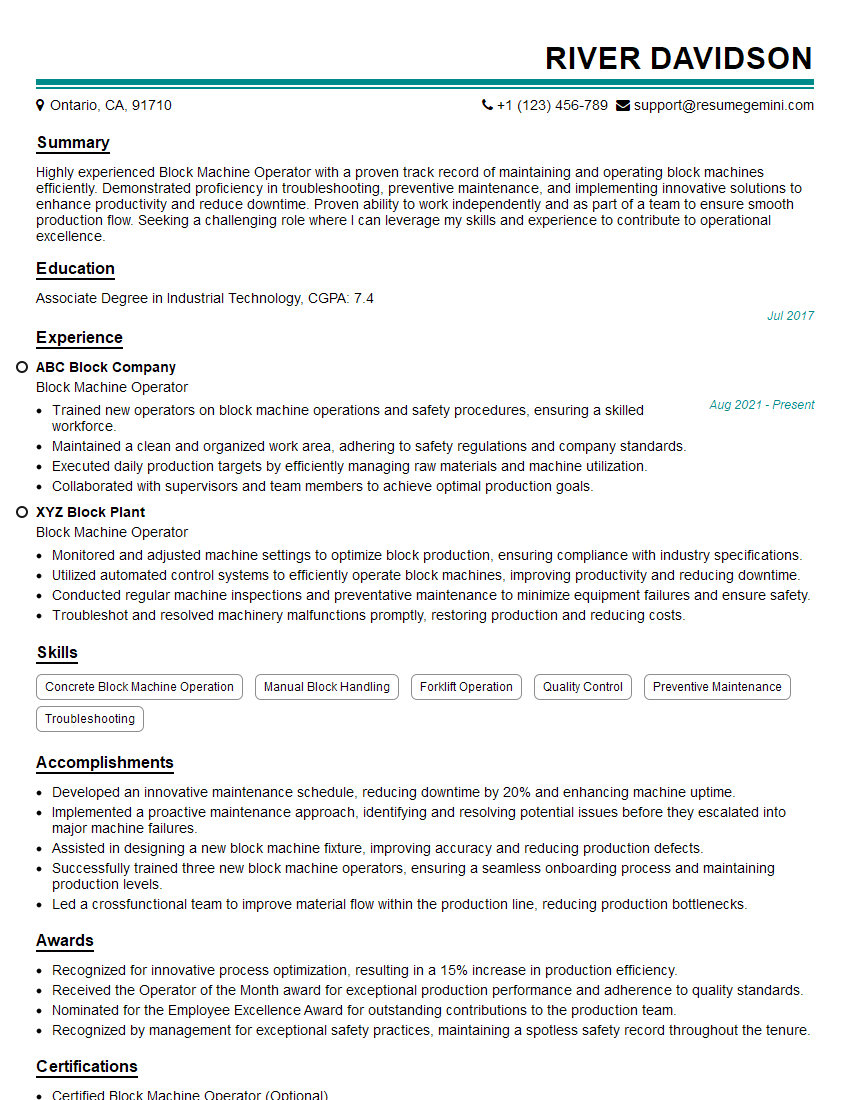

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Machine Operator

1. What are the different types of block machines and their applications?

- Hydraulic block machines: These machines use hydraulic pressure to compress the concrete mix into blocks.

- Mechanical block machines: These machines use mechanical force to compress the concrete mix into blocks.

- Automatic block machines: These machines are fully automated and can produce blocks at a high speed.

- Semi-automatic block machines: These machines require some manual operation, such as loading the concrete mix into the machine.

2. What are the main components of a block machine?

Drive system

- The drive system provides power to the machine.

- It consists of an electric motor, gearbox, and drive shaft.

Molding system

- The molding system shapes the concrete mix into blocks.

- It consists of a mold box, mold liners, and a tamper head.

Ejection system

- The ejection system pushes the finished blocks out of the mold box.

- It consists of an ejection plate, ejector pins, and a hydraulic cylinder.

3. What are the key factors to consider when selecting a block machine?

- The type of blocks you want to produce

- The production capacity you need

- The available space you have

- The budget you have

4. What are the common problems that can occur with block machines and how can they be solved?

- Block sticking to the mold: This can be caused by improper lubrication or worn mold liners.

- Blocks breaking during ejection: This can be caused by excessive force being applied during ejection or by weak concrete mix.

- Uneven block size: This can be caused by worn mold liners or by improper adjustment of the machine.

5. What are the safety precautions that should be taken when operating a block machine?

- Wear appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Keep the work area clean and free of debris.

- Inspect the machine regularly for any signs of damage.

- Do not operate the machine if you are tired or under the influence of alcohol or drugs.

6. What are the maintenance tasks that should be performed on a block machine?

- Lubricate the moving parts of the machine regularly.

- Inspect the mold liners for wear and replace them if necessary.

- Check the hydraulic system for leaks and repair any leaks that are found.

- Tighten all bolts and nuts on the machine.

7. What are the different types of concrete mixes that can be used in a block machine?

- Normal-weight concrete: This type of concrete is made with обычный aggregate, such as crushed stone or gravel.

- Lightweight concrete: This type of concrete is made with lightweight aggregate, such as expanded clay or shale.

- High-strength concrete: This type of concrete is made with a high proportion of cement and aggregate.

8. What are the different types of finishes that can be applied to concrete blocks?

- Smooth finish: This type of finish is achieved by troweling the surface of the concrete block.

- Textured finish: This type of finish is achieved by brushing or combing the surface of the concrete block.

- Split-face finish: This type of finish is achieved by splitting the surface of the concrete block.

9. What are the advantages of using concrete blocks for construction?

- Concrete blocks are strong and durable.

- Concrete blocks are fire-resistant.

- Concrete blocks are sound-proof.

- Concrete blocks are energy-efficient.

10. What are the disadvantages of using concrete blocks for construction?

- Concrete blocks are heavy.

- Concrete blocks can be expensive.

- Concrete blocks can be difficult to work with.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Block Machine Operator is responsible for the safe and efficient operation of a block making machine that produces concrete blocks.

1. Manage Overall Production

The primary responsibility of a Block Machine Operator is to manage the overall production process of concrete blocks. This involves:

- Setting up and calibrating the block machine

- Monitoring the production process to ensure that the machine is running smoothly

- Adjusting machine settings as needed to maintain optimal production levels

2. Quality Control

Block Machine Operators are also responsible for maintaining the quality of the concrete blocks produced. This includes:

- Inspecting blocks for defects

- Making adjustments to the machine or production process as needed to correct any quality issues

- Maintaining records of production and quality control

3. Equipment Maintenance

Block Machine Operators are also responsible for maintaining the equipment they use. This includes:

- Performing routine maintenance tasks

- Making minor repairs to equipment

- Reporting any major equipment issues to a supervisor

4. Safety and Compliance

Block Machine Operators must adhere to all safety regulations and company policies related to their work. This includes:

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures

- Maintaining a clean and organized work area

Interview Tips

To ace an interview for a Block Machine Operator position, it is important to prepare adequately. Here are some tips:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you better understand the company’s culture and the job requirements.

- Visit the company website to learn about their history, mission, and products or services.

- Look up the job description for the position you are applying for.

2. Prepare Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to prepare your answers to these questions ahead of time.

- When answering “Tell me about yourself,” focus on highlighting your relevant skills and experience.

- For “Why are you interested in this position?” explain how your skills and interests align with the job requirements and company culture.

3. Practice Your Answers

Once you have prepared your answers to common interview questions, practice delivering them out loud. This will help you become more comfortable and confident during the actual interview.

- You can practice with a friend, family member, or career counselor.

- Record yourself practicing and watch it back to identify areas for improvement.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your appointment.

- Choose clothing that is clean, pressed, and appropriate for an office environment.

- Plan your route to the interview location ahead of time to avoid getting lost or delayed.

Next Step:

Now that you’re armed with the knowledge of Block Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Block Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini