Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Block Placer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

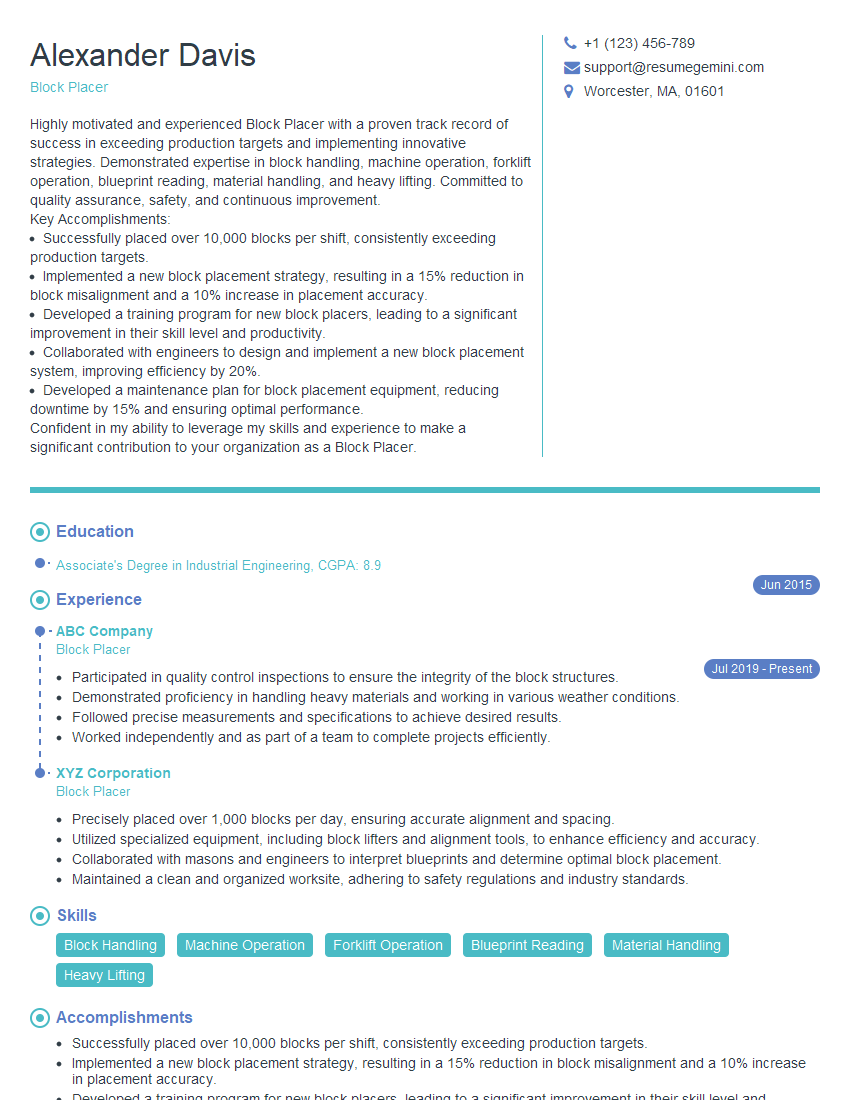

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Placer

1. What are the different types of blocks used in construction, and how do you choose the right block for a particular project?

- Concrete blocks: These are the most common type of block used in construction. They are made from a mixture of cement, sand, and gravel, and are available in a variety of sizes and shapes.

- Clay bricks: Clay bricks are made from clay that has been fired in a kiln. They are stronger and more durable than concrete blocks, but they are also more expensive.

- Stone blocks: Stone blocks are made from natural stone, such as granite or limestone. They are the most durable type of block, but they are also the most expensive.

- Foam blocks: Foam blocks are made from a lightweight material, such as polystyrene or polyurethane. They are not as strong as concrete blocks or clay bricks, but they are very lightweight and easy to install.

2. What are the different techniques for placing blocks?

- Laying blocks in a straight line: This is the most common technique for placing blocks. The blocks are laid in a straight line, one on top of the other, with mortar in between each block.

- Laying blocks in a staggered pattern: This technique is used to create a stronger wall. The blocks are laid in a staggered pattern, so that the joints between the blocks are not aligned.

- Laying blocks in a herringbone pattern: This technique is used to create a decorative wall. The blocks are laid in a herringbone pattern, so that they form a zig-zag pattern.

3. What are the different types of mortar used in block construction?

Types of mortar

- Type N mortar: This type of mortar is used for general purpose construction. It is made from a mixture of cement, sand, and lime.

- Type S mortar: This type of mortar is used for structural applications. It is made from a mixture of cement, sand, and fly ash.

- Type M mortar: This type of mortar is used for heavy-duty applications. It is made from a mixture of cement, sand, and crushed stone.

Uses of mortar

- Mortar is used to bond blocks together.

- Mortar is used to fill the joints between blocks.

- Mortar is used to level blocks.

- Mortar is used to create a weather-resistant seal.

4. What are the safety precautions that must be taken when working with blocks?

- Wear protective clothing, such as gloves, safety glasses, and a hard hat.

- Use proper lifting techniques when moving blocks.

- Be aware of the location of overhead power lines.

- Do not work on scaffolding that is not properly constructed.

- Follow all safety regulations.

5. What are the common problems that can occur when placing blocks?

- Uneven blocks: Uneven blocks can be caused by a variety of factors, such as improper leveling or settling of the foundation.

- Cracked blocks: Cracked blocks can be caused by a variety of factors, such as excessive weight or impact.

- Leaking mortar joints: Leaking mortar joints can be caused by a variety of factors, such as improper mixing or application of the mortar.

- Efflorescence: Efflorescence is a white or gray powder that can form on the surface of blocks. It is caused by the evaporation of water from the blocks.

6. What are the different tools and equipment used by block placers?

- Mason’s trowel

- Level

- Line level

- Mortar mixer

- Block cutter

- Safety glasses

- Gloves

- Hard hat

7. What are the qualities of a good block placer?

- Attention to detail

- Accuracy

- Precision

- Strength

- Endurance

- Teamwork

- Communication skills

8. What are the career opportunities for block placers?

- Block placer

- Mason

- Concrete finisher

- Construction supervisor

- Project manager

9. What are the salary expectations for block placers?

The salary expectations for block placers vary depending on the experience and location. According to the Bureau of Labor Statistics, the median annual salary for block placers was $39,810 in May 2021. The lowest 10 percent earned less than $22,700, and the highest 10 percent earned more than $66,580.

10. What is the job outlook for block placers?

The job outlook for block placers is expected to be good over the next few years. The construction industry is expected to grow, and this will create more demand for block placers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Placer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Placer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Block Placers are responsible for setting, aligning, and leveling blocks or bricks used in the construction of walls, partitions, and other structures.

1. Block and Brick Placement

Accurately place blocks or bricks according to blueprints or specifications.

- Set and level the first course of blocks or bricks.

- Build walls, partitions, and other structures by stacking and aligning blocks or bricks.

- Cut and shape blocks or bricks to fit specific dimensions.

2. Mortar Application

Apply mortar between blocks or bricks to bind them together.

- Prepare mortar by mixing sand, cement, and water.

- Spread and smooth mortar onto blocks or bricks.

- Strike off excess mortar to create a level surface.

3. Reinforcement Installation

Install reinforcement bars or mesh to strengthen structures.

- Position and secure reinforcement bars or mesh according to specifications.

- Inspect reinforcement for proper placement and alignment.

4. Quality Control

Ensure the quality of the finished product.

- Check for levelness, alignment, and plumbness throughout the construction process.

- Make adjustments as needed to maintain accuracy and meet specifications.

- Clean and finish surfaces as required.

Interview Tips

Preparing for a Block Placer interview requires a strong understanding of the job responsibilities and industry practices. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s culture, values, and recent projects.

- Visit the company website and social media pages.

- Read industry publications and news articles.

- Network with professionals in the field.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in block and bricklaying techniques, mortar application, and reinforcement installation.

- Quantify your accomplishments with specific examples.

- Showcase your ability to work independently and as part of a team.

- Demonstrate your attention to detail and commitment to quality.

3. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and motivation.

- Why are you interested in this position?

- Describe your experience in block and bricklaying.

- How do you ensure the accuracy and quality of your work?

4. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving for the interview on time.

- Wear clean, pressed clothing that is appropriate for a construction environment.

- Arrive 10-15 minutes early to demonstrate your punctuality and respect for the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Block Placer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!